2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

In mining, rock drilling directly affects the speed, quality, safety and cost of engineering construction. Therefore, according to the characteristics of different projects, many tools and equipment are generally used on the construction site, such as rock drilling tools. What are rock drilling tools?

1. The meaning of rock drilling tools

The rock drilling tool is the working tool for rock drilling, that is, the collective name of the connecting rod shank, the drill rod, the connecting sleeve, the drill head, and the whole drill. The main products are: light-duty rock drilling tools, down-the-hole rock drilling tools, drilling tools for hydraulic rock drilling rigs and other types of drilling tools. Because the rock drilling tools include a wide range and are classified into many categories, we select the main parts of the rock drilling tools for a brief introduction.

Because the rock drilling tools include a wide range and are classified into many categories, we select the main parts of the rock drilling tools for a brief introduction.

2. Classification of rock drilling tools

A. Top hammer rock drilling tools The top hammer impact rock drilling is that the rock drilling machine is located at the top of the drill tool, and the rock drill piston directly hits the rear end of the drill tool, and the impact energy generated is in the form of stress wave through the rod body to reach the drill bit to do work on the rock. The rock drilling machine uses compressed gas or hydraulic oil as the power source, and the impact power can be designed according to the requirements of the equipment, so it has a higher rock drilling rate. It can be mainly divided into drill tools for light rock drills, drill tools for underground mining, drill tools for rock drilling and excavation, and drill tools for full hydraulic open-pit rock drilling rigs.

The top hammer impact rock drilling is that the rock drilling machine is located at the top of the drill tool, and the rock drill piston directly hits the rear end of the drill tool, and the impact energy generated is in the form of stress wave through the rod body to reach the drill bit to do work on the rock. The rock drilling machine uses compressed gas or hydraulic oil as the power source, and the impact power can be designed according to the requirements of the equipment, so it has a higher rock drilling rate. It can be mainly divided into drill tools for light rock drills, drill tools for underground mining, drill tools for rock drilling and excavation, and drill tools for full hydraulic open-pit rock drilling rigs.

B. Down-the-hole rock drilling tools

Different from the top hammer type rock drilling tool, the down-the-hole type rock drilling tool is a medium and large-diameter rock drilling machine that uses compressed air as the power source to enter the power part into the rock hole for rock drilling. The application of external rock drilling engineering is very extensive. Down-the-hole percussion rock drilling tools are usually composed of three parts: a drill bit, an impactor and a drill pipe, which are equipped on a drilling rig (drill stand) and equipped with an air compressor to form a rock drilling unit. According to the pressure of the compressed air used by DTH percussion drilling tools, it is usually divided into low-pressure DTH drilling tools (pressure 0.6-0.8MPa), medium and high pressure DTH drilling tools (pressure 1.0-2.0MPa), high pressure DTH drilling tools (pressure 1.0-2.0MPa).

C. Mining roller cone drill tools

Mining roller cone drilling tools are mainly used for vertical perforation operations in large-scale open-pit mines, earth-rock excavation, water wells and geothermal wells. During the drilling process, the roller cone drill drives the roller cone bit to rotate through the drill rod, and at the same time applies downward thrust to penetrate the hole. Under the rotational force, the roller cone drill drives three roller cones with carbide teeth or steel teeth to rotate around their respective claw journals, and at the same time, under the action of axial thrust, the alloy teeth or steel teeth It is embedded in the rock surface, and the rock is broken by the combined force of extrusion and shearing, so as to achieve the purpose of perforation.

D. (Reverse) Raise drilling tools

The rock drilling bit of the raise drilling tool is composed of a rolling scraping bit and a bracket inlaid with cemented carbide teeth, and the drilled hole diameter ranges from φ500 mm to 6000 mm.

F. Drilling tools for geological exploration

Geological exploration drilling tools are a type of rock drilling tools. Some well-known rock drilling tool manufacturers have their own complete production systems for geological exploration drilling tools.

G. Mechanical cutting drill

The mechanical cutting and drilling process is a non-drilling and blasting construction technology that uses the power generated by the drilling machine to drive the drilling tools to cut the rock and soil to complete the drilling and excavation construction. Mainly divided into trenchless engineering drilling tools, shearer picks, pavement cold milling machine picks, tunnel excavation shield machine tools, slotting machine picks and road grader picks.

The above is mainly classified according to the type of rock drilling machinery used in geotechnical drilling and excavation engineering. Since top hammer rock drilling tools are used more, we will mainly introduce the composition of the top hammer rock drilling tools to you.

3. Composition of top hammer rock drilling tools

A. Drill bit The drill bit is an indispensable tool in the field of drilling. According to different operation and construction requirements, the drill bit has different classification methods. According to the shape of the rock drilling alloy, the drill bit can be divided into sheet drill bit, ball-tooth drill bit and Chip-tooth composite drill bit, Sheet Drill Bit: in-line type, three-blade type, cross type/X type,Ball Tooth Bit: pants body, bit head, ball tooth,The applilcation of different drill bits varies.

The drill bit is an indispensable tool in the field of drilling. According to different operation and construction requirements, the drill bit has different classification methods. According to the shape of the rock drilling alloy, the drill bit can be divided into sheet drill bit, ball-tooth drill bit and Chip-tooth composite drill bit, Sheet Drill Bit: in-line type, three-blade type, cross type/X type,Ball Tooth Bit: pants body, bit head, ball tooth,The applilcation of different drill bits varies.

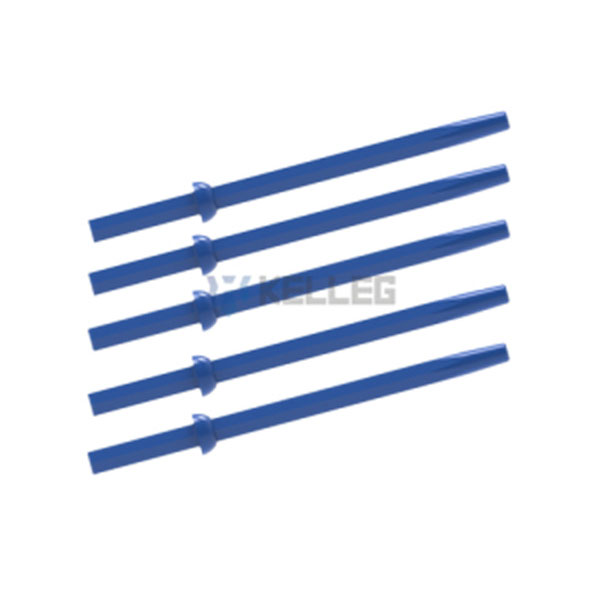

B. Drill rod The drill rod is also an indispensable part of the rock drilling tool. It is mainly used to connect the drill bit and the rock drilling tool. The drill rod also has different classifications, such as integral drill, quarry drill, cone connection drill rod, thread Connect the drill rod, etc.

The drill rod is also an indispensable part of the rock drilling tool. It is mainly used to connect the drill bit and the rock drilling tool. The drill rod also has different classifications, such as integral drill, quarry drill, cone connection drill rod, thread Connect the drill rod, etc.

C.Coupling sleeve  The coupling sleeve is used to connect the drill rod and the drill rod, and connect the drill rod and the drill tail, and has a sleeve with internal thread.

The coupling sleeve is used to connect the drill rod and the drill rod, and connect the drill rod and the drill tail, and has a sleeve with internal thread.

D. Drill adapter Can be a separate interface device, connected to the drill bit.

Can be a separate interface device, connected to the drill bit.

E.Shank sleeve  The shank sleeve has a certain gap in the equipment, and each impact of the drilling rig makes the shank sleeve stress, which is transmitted to the drill rod and drill bit through the force of the shank sleeve.

The shank sleeve has a certain gap in the equipment, and each impact of the drilling rig makes the shank sleeve stress, which is transmitted to the drill rod and drill bit through the force of the shank sleeve.

Rock drilling can be applied to many fields and can be produced in many ways. Rock drilling tools are the core products that everyone pays attention to in the industry. What are their specific applications in the field of rock drilling?

4. The application of rock drilling tools in the field of rock drilling

A. Hand-held rock drilling

Hand-held rock drilling is rock drilling performed with a hand-held light rock drill. It is mainly used in small construction sites or environments where larger equipment cannot be used in limited space.

B. Mechanical rock drilling

In mechanical rock drilling, operators often monitor two or three rock drills. Rock drills are mounted on thrusters or glide arms. Equipment that carries pushers or sliding arms for mechanized rock drilling is called a drilling rig.

C. Terrace rock drilling

Terrace rock drilling is a mining method in which blasting holes are drilled on terraces for terrace blasting. It is a relatively simple way of rock drilling.

D. Rock drilling for level road excavation

Rock drilling is a rock drilling operation method for blasting rock holes in tunnels or air-raid shelters.

E. Production of rock drilling (medium and deep holes)

Production rock drilling refers to the drilling of blasting rock holes in an ore body, or the extraction of production rock in a quarry. Therefore, this rock drilling method is suitable for open pit mines, quarries and underground mines. Usually for deep hole drilling or terrace mining.

F. Support rock drilling

Support rock drilling is used to prevent roadway and rock from slumping. First, a rock hole is drilled in the rock, and then the expansion bolt or grouting bolt is installed. The bolt reinforces the surrounding rock that may loosen and fall off.

G. Lifting and drilling rock

Vertical phase channels are often required in wells or other underground shelters. The vertical channel can now be drilled over the entire face using the lift-drilling method.

H. Overload rock drilling

When drilling foundation pile holes, anchor holes or water well holes (sometimes also used for blasting work holes), it may be more advantageous to use the overload rock drilling method.

As a supporting tool for rock drilling equipment, rock drilling tools have a wide range of product specifications and types, a wide range of application fields and different methods of use, so I cannot introduce them all in one article. Companies who are interested in this or have related product requirements can continue to pay attention and contact us, Kelleg will be happy to provide you with high-quality products and services.