2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

-Light weight and high tensile strength: The GFRP bolt has high tensile load, but the weight is only one quarter of metal product. It is especially suitable for projects that need to reduce the weight of structure, such as replacing steel bars to make glass fiber cages, glass fiber reinforced walls and glass fiber reinforced beams.

-Corrosion resistance: GFRP is a good corrosion-resistant material, and has good resistance to atmosphere, water and general concentrations of acids, alkalis, salts, and a variety of oils and solvents.

-Good safety performance: It doesn’t produce sparks when be cut due to flame-retardant and anti-static, and it can be safely constructed in flammable and explosive environments such as roadway engineering.

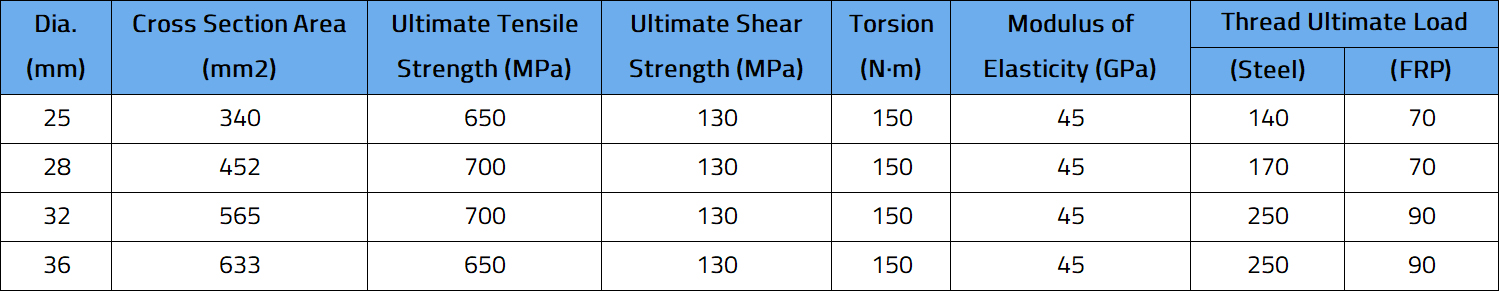

GFRP Solid Bolt in Civil Engineering

In civil engineering, GFRP solid bolt can be widely used in foundation, slopes, mines, tunnels, etc., and can also be used as reinforcements for building concrete.

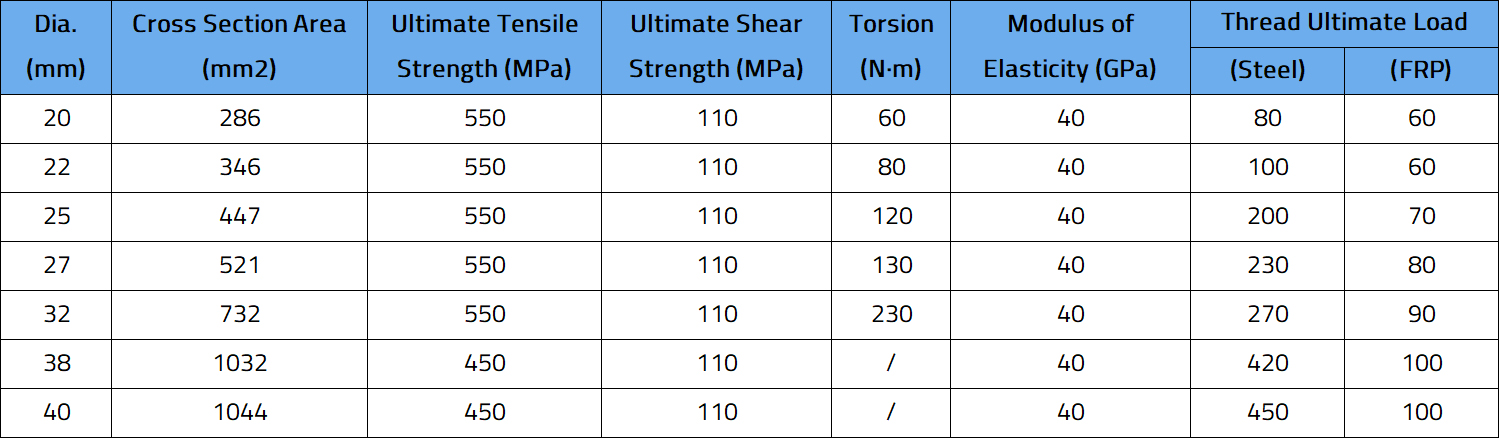

GFRP Hollow Bolt in Support Engineering

In supporting projects, the GFRP hollow bolt has the function of grouting, which can be injected with cement grout or other materials as anchoring agent to increase the bonding area of the rod and grout, and make the supporting effect more excellent.