2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Pneumatic rock drills are indispensable equipment in engineering fields such as mines and tunnels. The noise issue arising from their operation has consistently been a focal point within the industry. In particular, the noise of the drill rod not only affects the physical and mental health of the operator but may also cause interference with the surrounding environment. Therefore, it is crucial to control the noise of the drill rod of a pneumatic rock drill. This article will introduce some simple and easy-to-understand methods to help you effectively control the noise of the drill rod of your pneumatic rock drill.

Understand the sources of noise

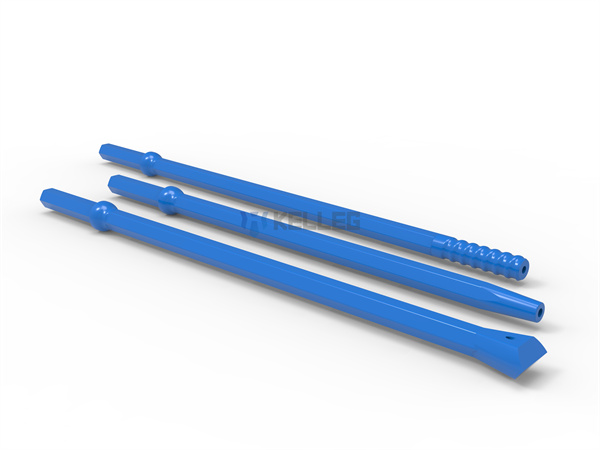

To effectively control the noise emitted by the drill rod of the pneumatic rock drill, it’s essential to understand its source. The noise primarily stems from the lateral vibration of the drill rod, with its frequency range concentrated in the high-frequency spectrum. Noise mitigation for the drill rod focuses on two key aspects: 1) minimizing bending waves and 2) reducing the acoustic radiation of these bending waves.

Methods to reduce bending waves

1.Reduce the matching gap between the shank sleeve and the shank adapter.

2.Increase the length of the shank adapter.

3.Ensure that the rotating sleeve is aligned with the inner hole of the cylinder in the rock drill.

4.Cancel the forged drill shoulder on the drill rod.

5.Best shaft thrust.

6.Use low-noise alloy steel to make drill rods.

Reduce the acoustic radiation of bending waves

1.Use rubber drill shoulder to attenuate bending waves.

2.Drill rod shielding sleeve.

3.Use concentric drill rod.

4.Paste elastic damping material on the drill rod.

Choose low-noise equipment

Choosing a low-noise pneumatic rock drill is the fundamental measure to control noise. When purchasing equipment, you can pay attention to the equipment’s noise indicators and choose low-noise equipment that meets national or industry standards. At the same time, we can also consider purchasing rock drills with noise-reduction devices to further reduce the noise level.

Optimize working environment

Optimizing the working environment is also an effective way to reduce the noise of the drill rod of pneumatic rock drills. At the construction site, sound barriers or walls can be set up to reduce the spread of noise. At the same time, work hours should be reasonably arranged to avoid high-noise operations during rest periods or at night, reducing the impact on surrounding residents.

Improve the rock drilling process

Reasonable rock drilling technology can also reduce the noise of the drill rod to a certain extent. For example, adjusting the impact frequency and force of the rock drill can ensure smoother impact on the rock, thereby reducing vibration and noise. Also, a well-planned arrangement of rock drilling sequence and depth can help avoid excessive impact, further reducing noise levels.

Regularly inspect and maintain the drill rods

As a critical component of the pneumatic rock drill, the condition of the drill rod directly affects the generation of noise. Regularly checking the wear and damage of the drill rods and timely replacing the badly worn ones can keep the equipment in the best working condition and reduce noise generation. At the same time, lubricating and cleaning the drill rod can ensure its surface is smooth and reduce the noise level to a certain extent.

Proper use and maintenance of equipment

Proper use and maintenance of pneumatic rock drills are equally vital in controlling drill rod noise. During use, ensure the drill rod is firmly connected to the rock drill to avoid additional noise caused by looseness or vibration. In addition, regular maintenance and upkeep of the equipment to keep the equipment in good condition can also reduce noise generation to a certain extent.

Strengthen operator protection

In addition to the above methods, the operator still needs to take definite protective measures. We wear personal protective equipment such as earplugs or earmuffs, which can effectively isolate noise and protect hearing. At the same time, regular hearing checks are conducted on operators to detect and deal with hearing loss problems promptly.

Training and guidance

Relevant training and guidance for operators is also an essential part of noise control. Through training, operators can understand the principles of noise generation and control methods and master correct operating skills and maintenance methods. Additionally, organizing regular safety education and publicity activities to raise operators’ awareness of safety and noise control is also an effective measure to reduce noise.

Innovative noise reduction technology

With the advancement of science and technology, more and more innovative noise reduction technologies are applied in engineering. We can consider adopting advanced noise reduction technologies to reduce drill rod noise. For example, develop new silencing materials or silencing structures to improve the design of rock drills; research new vibration control technologies to reduce the vibration noise of the drill rod during the rock drilling process, etc.

Conclusion

Controlling the noise of the drill rod of a pneumatic rock drill requires starting from many aspects. Through the comprehensive application of these measures, we can effectively reduce the noise level of the drill rod and protect the physical and mental health of the operator and the tranquility of the surrounding environment. At the same time, this will also help improve the safety and efficiency of projects and promote sustainable development in mining, tunnels, and other engineering fields.