2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

In mining, tunnel construction, geological exploration, and other projects, top hammer rock drills are essential equipment. As a core component of a top hammer rock drill, the selection of the rock drill bit directly impacts the project’s efficiency and quality. This article will introduce you to the classification of top hammer rock drill bits in detail, helping you easily choose a suitable bit and improve project efficiency.

What is a top hammer rock drill bit?

The top hammer rock drill bit is a crucial component of the top hammer rock drilling tool. Its function is to transfer the impact energy of the rock drill to the rock to achieve rock crushing and drilling. Due to different rock characteristics and engineering requirements, top hammer rock drill bits have different classifications.

Types of top hammer rock drill bits

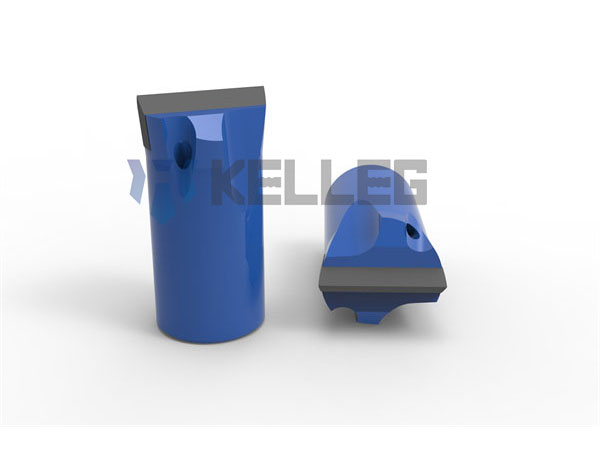

Chisel bit

It has a relatively simple manufacturing process, convenient regrinding, reliable work, and strong adaptability to rock mass performance. It is often used with light internal combustion, electric, pneumatic, and hydraulic rock drills to drill rock holes with a diameter of less than 50mm in various types of rock.

Cross bit

The diameter of the drill bit is in the range of 29-48mm, and it has strong adaptability to rock drilling conditions and is almost not limited by the rock drilling type and rock mass.

Button bit

The button bit consists of a tungsten carbide button inlaid on the drill bit body. It can break at multiple points and has higher rock-breaking efficiency. It can not only effectively eliminate the blind area of rock breaking but also avoid repeated breaking of rock debris. Common button bits are as follows:

Standard button bit

The standard button bit is suitable for drilling operations under typical geological conditions. It features a simple structure with evenly distributed buttons, making it suitable for various hardness levels of rock formations.

Retrac button bit

The retract button bit is mainly used in a loose rock mass with relatively broken rocks. The retract skirt body design can assist in retracting the drilling tool, reduce the phenomenon of drill sticking and buried drill, and help improve the straightness of drilling.

Reaming button bit

The reaming button bit, also known as the reaming guide bit, is a drilling tool used for reaming operations. It initially drills a pilot hole to a certain depth and reaches a larger hole diameter, mainly used for center hole reaming in deep hole drilling.

How to choose a suitable top hammer rock drill bit?

When choosing a suitable top hammer drill bit, you need to consider the following factors:

Rock characteristics: select the appropriate drill bit material and shape according to the hardness, toughness, abrasiveness, and other characteristics of the rock.

Project requirements: select the appropriate drill bit type and specifications based on the project’s specific needs. For instance, for projects requiring rapid drilling, a carbide drill bit is ideal; for projects needing to enlarge the hole diameter, a reaming button bit is suitable.

Rock drill type: different rock drills have different impact forces and frequencies. We should choose a drill bit that matches the rock drill to ensure that it matches the model and specifications of the rock drill.

Cost budget: select the appropriate drill bit material and specifications based on the cost budget.

Maintenance of top hammer rock drill bit

To prolong the service life of the top hammer rock drill bits and to improve drilling efficiency, they should be maintained and serviced regularly. Here are some suggestions:

1.Regularly check the wear of the drill bit, and promptly replace seriously worn carbide buttons or drill bits.

2.Clean the impurities and oil on the surface of the bit and the drill hole before use to ensure good cooperation between the bit and the rock drill.

3.Avoid excessive impact and overload during use to avoid damaging the bit.

4.Lubricate and anti-rust the drill bit regularly to maintain its good working condition.

Conclusion

Top hammer rock drill bits are an indispensable and vital tool in mining, tunnel construction, geological exploration, and other projects. Selecting the right drill bit is crucial for enhancing engineering efficiency and quality. By understanding the classification of top hammer rock drill bits, we can more clearly and accurately select products suitable for the project.