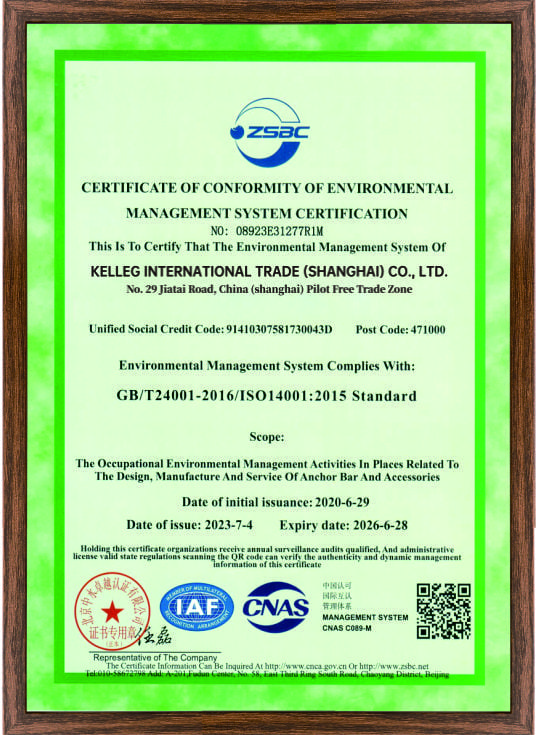

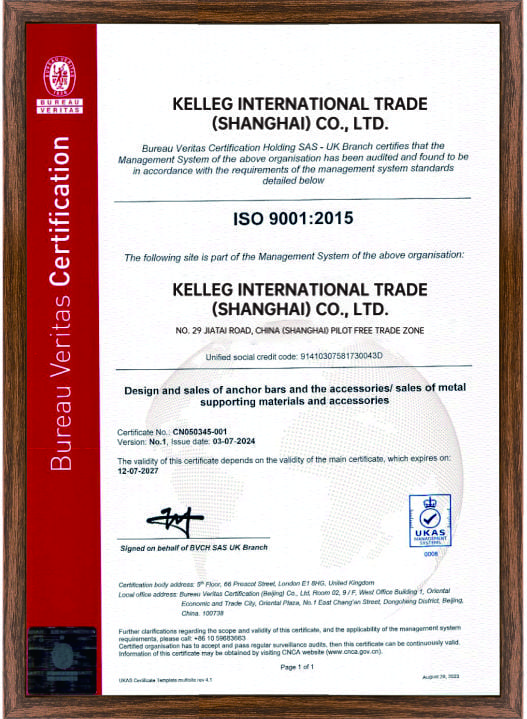

At Kelleg, we are committed to providing high-quality products and services through ongoing improvement and innovation. Our objective is to elevate quality standards and competitiveness to meet and surpass customer expectations. Over the years, we have established and maintained the ISO 9001 Quality Management System, ISO 14000 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System, ensuring the efficient operation of all management processes. Additionally, we collaborate with SGS, a third-party inspection agency, to drive continuous quality improvements.

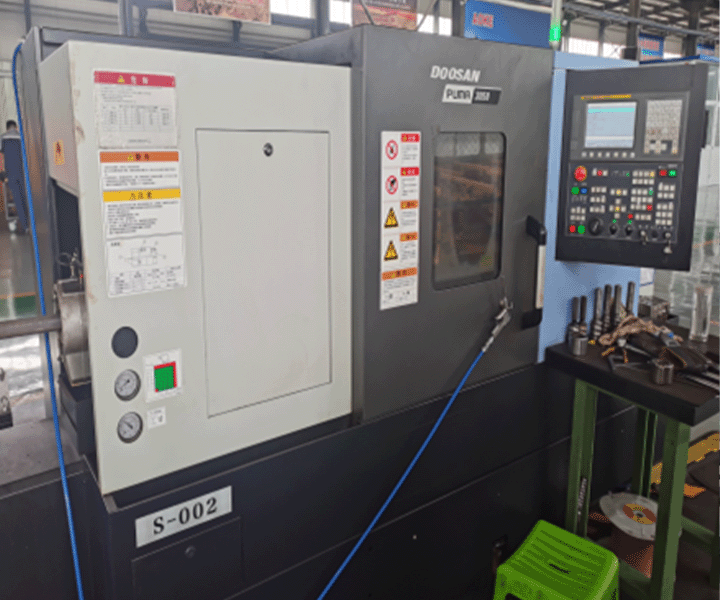

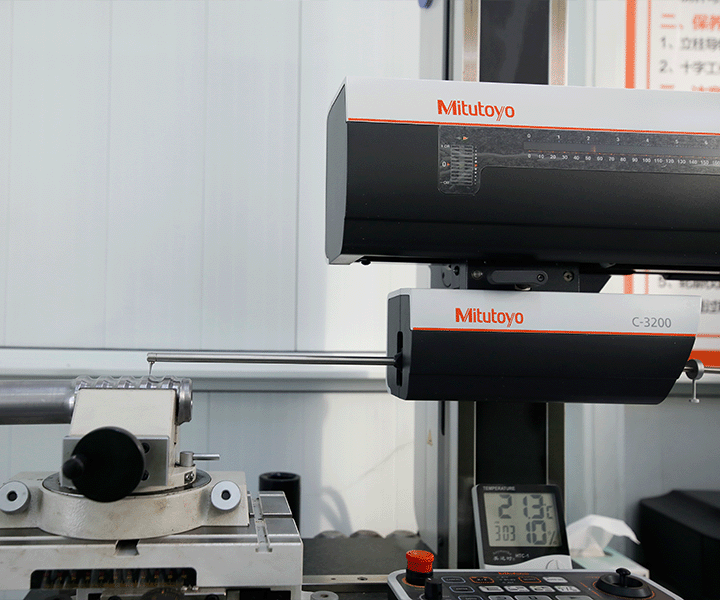

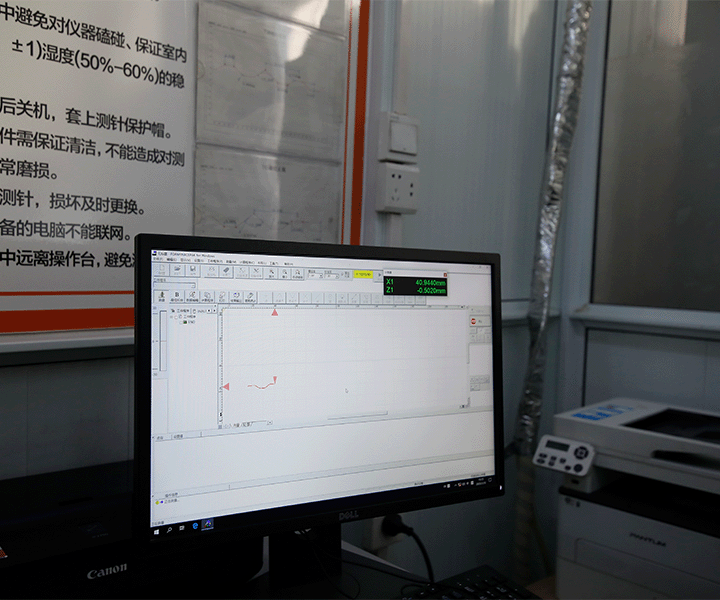

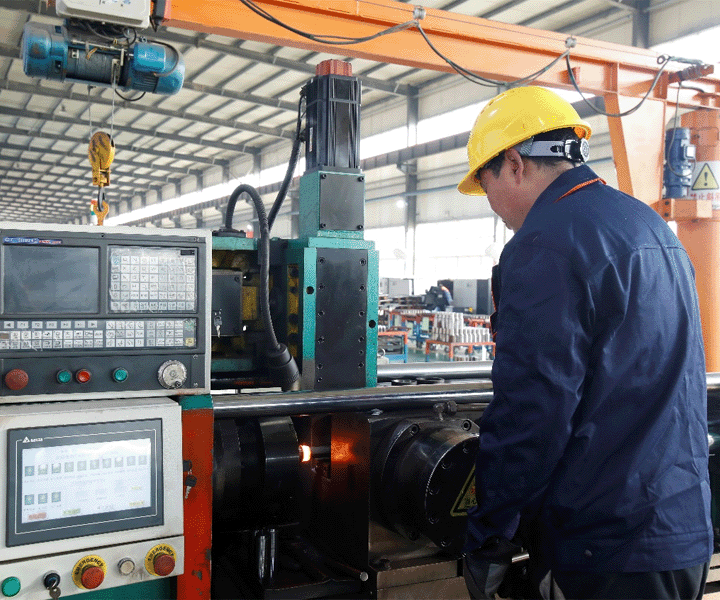

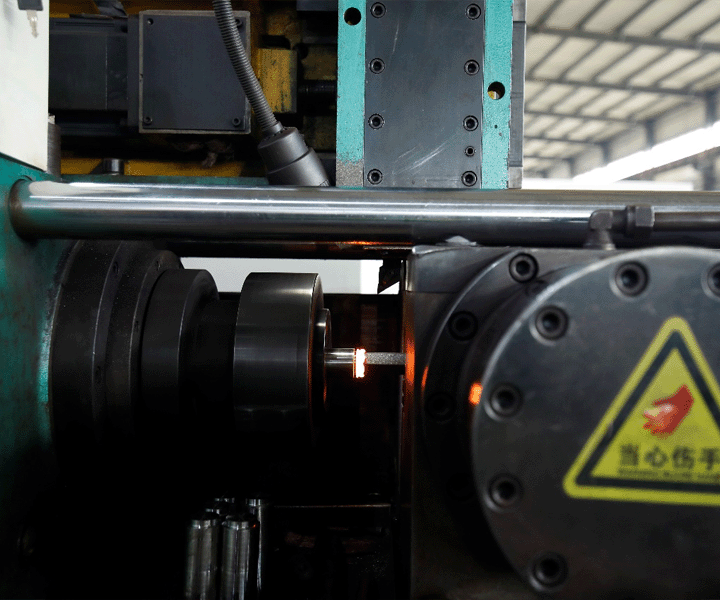

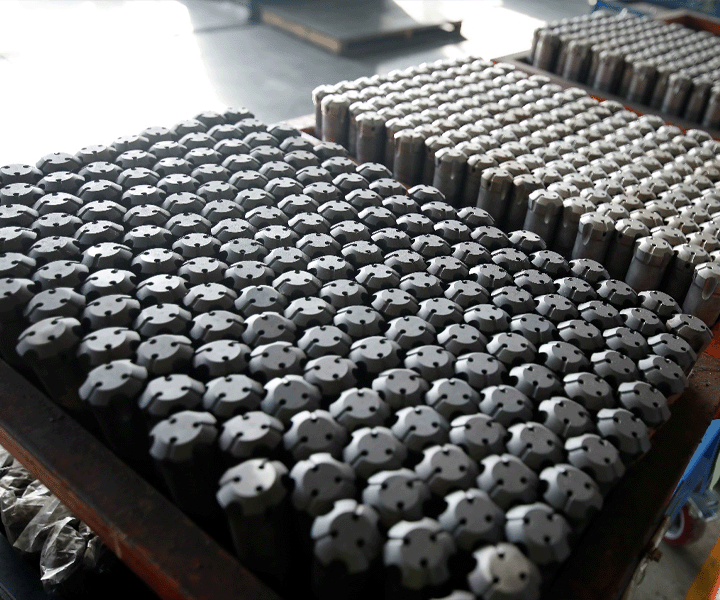

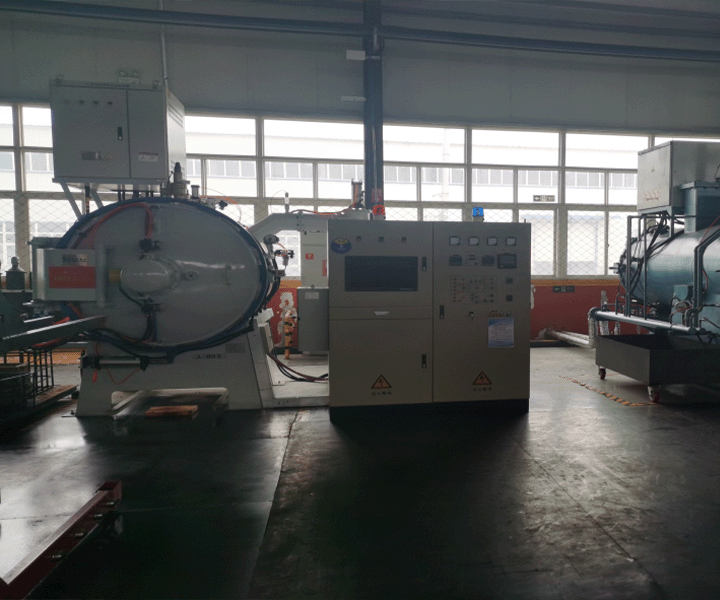

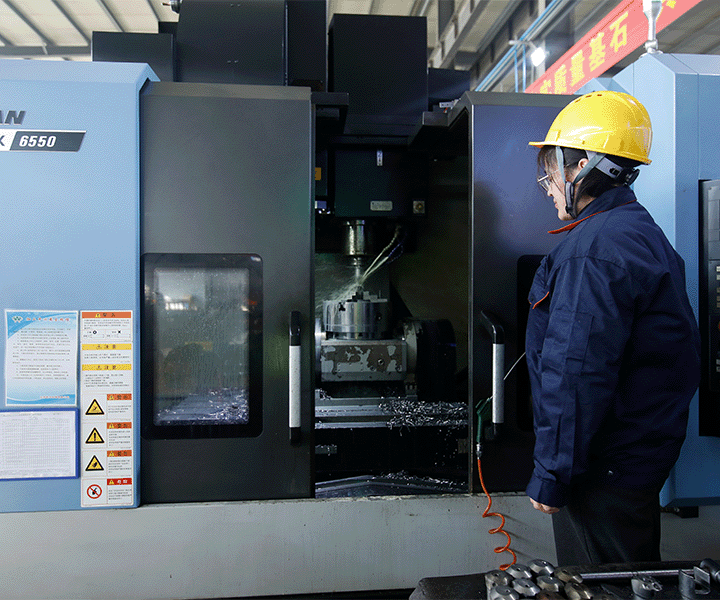

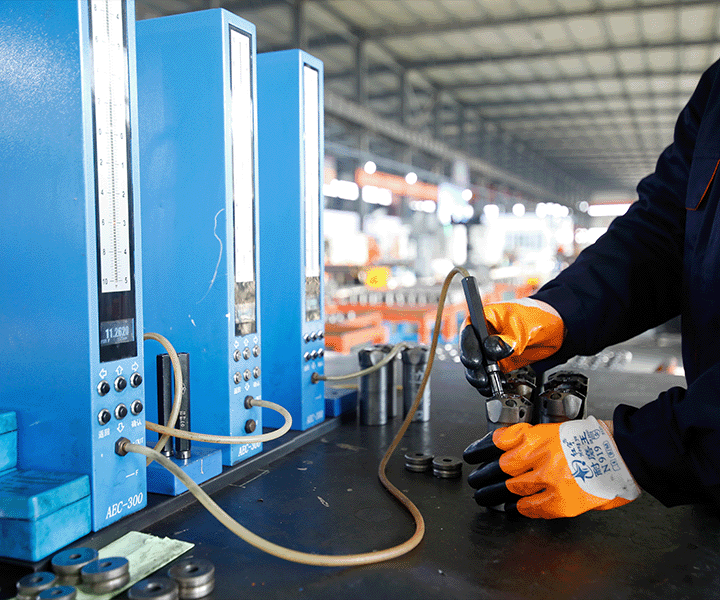

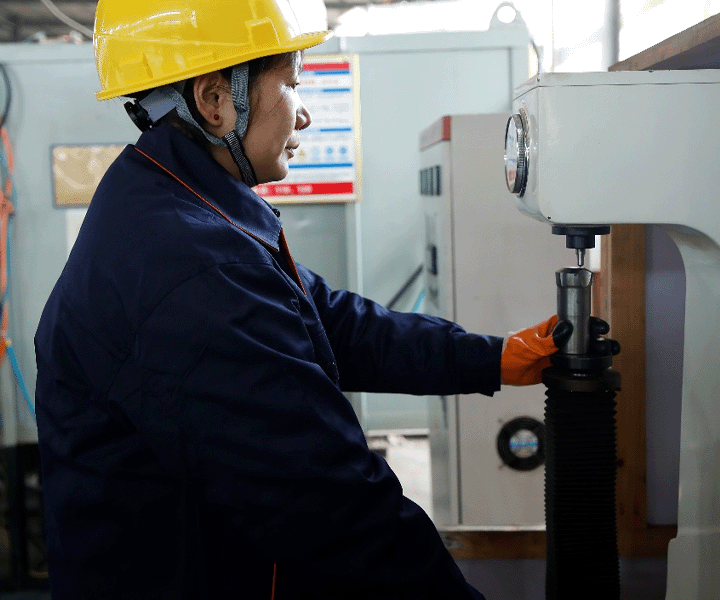

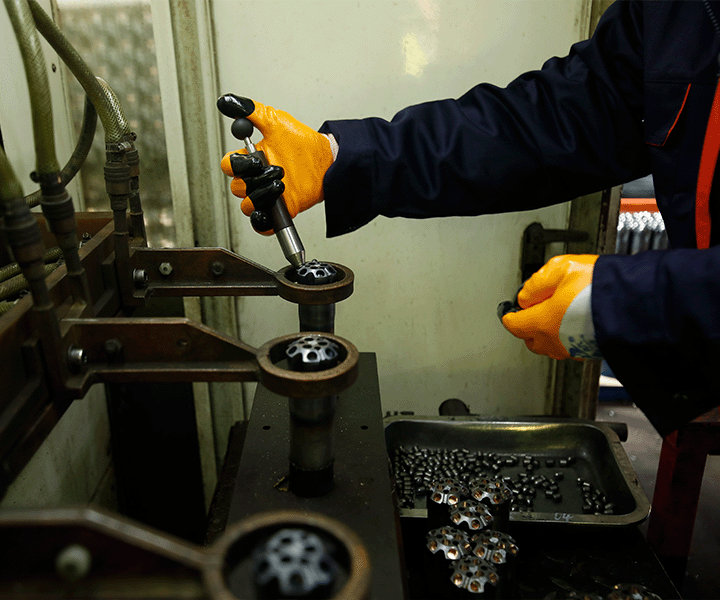

Our quality management process encompasses four key stages: supplier management, incoming material inspection, in-process inspection, and final product inspection. This comprehensive quality control process ensures meticulous monitoring at every stage, from raw materials to finished products, providing customers with reliable, high-performance items.