Introduction

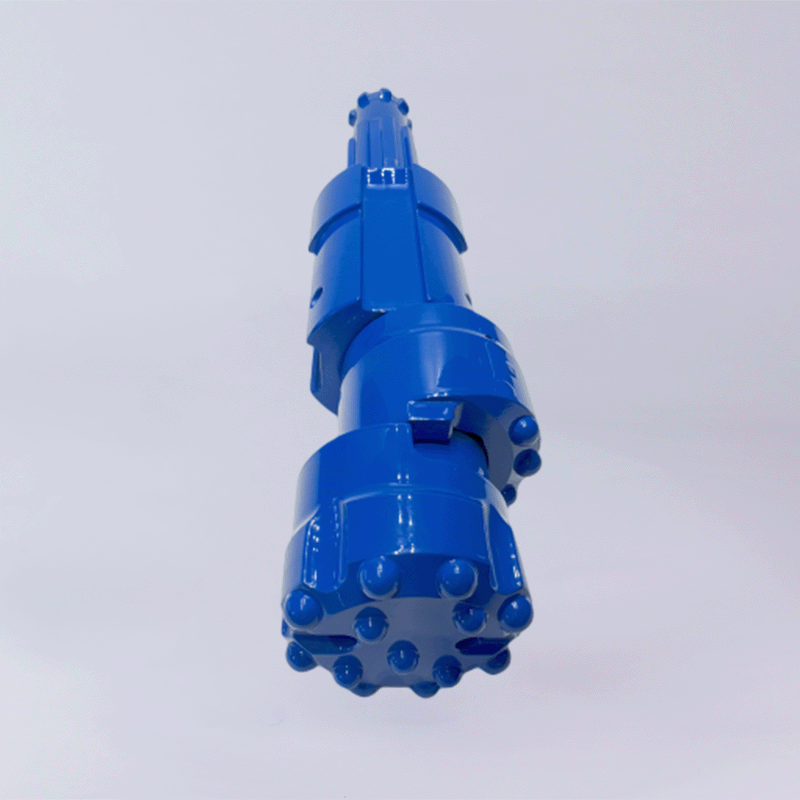

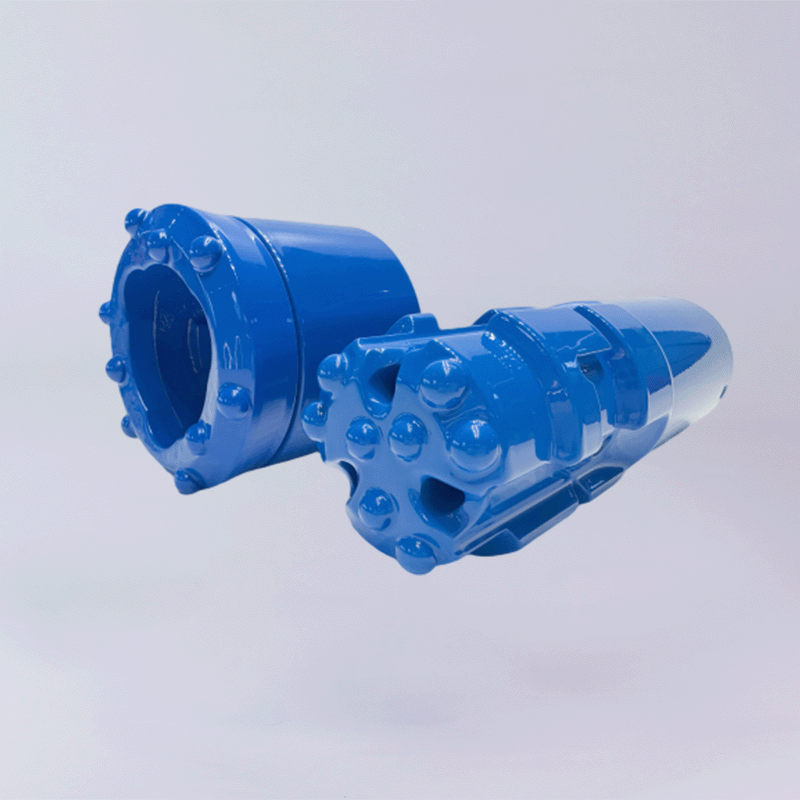

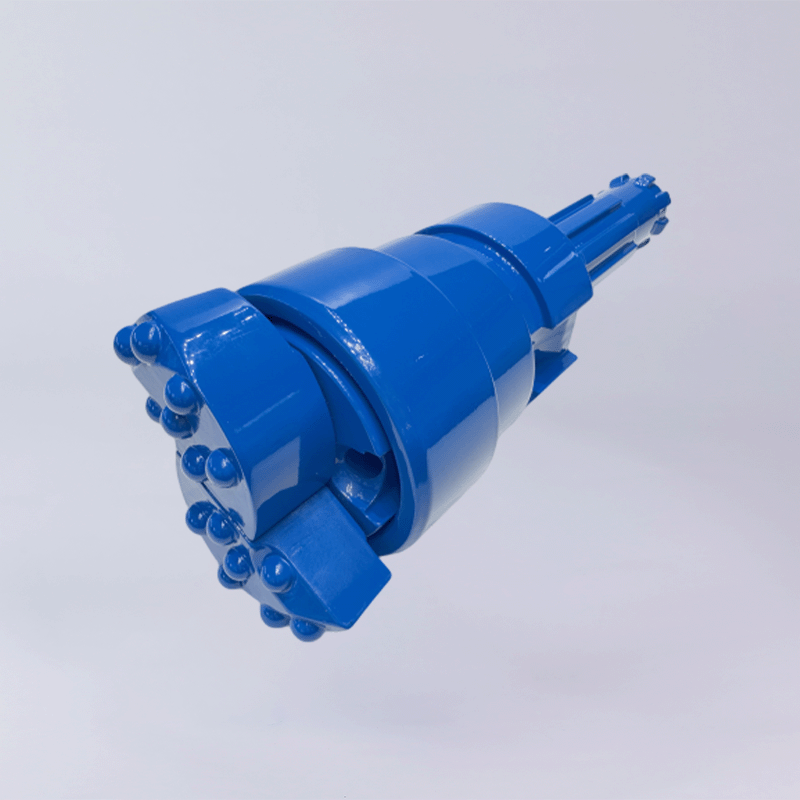

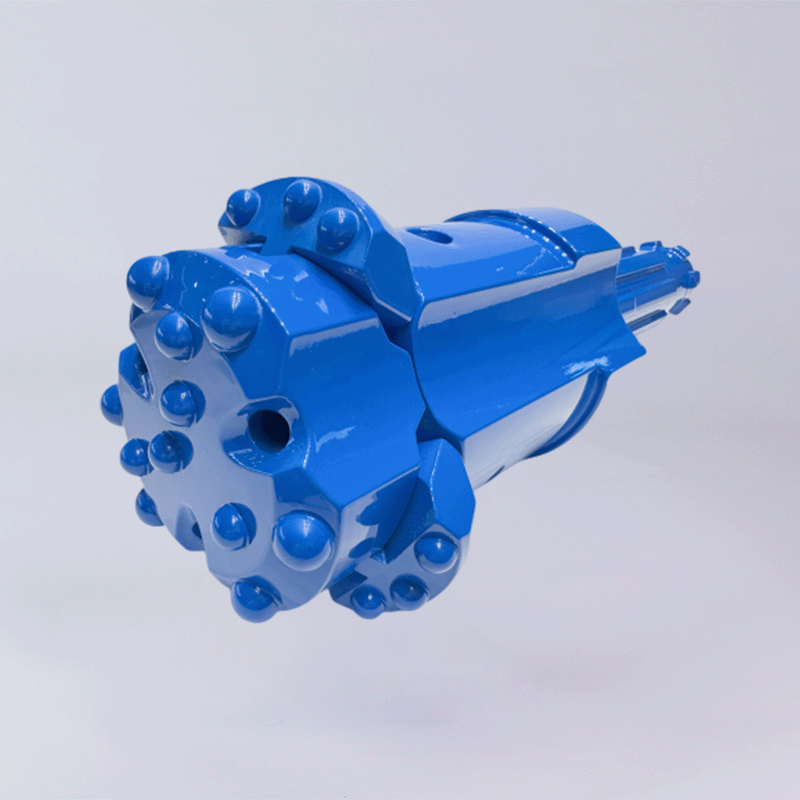

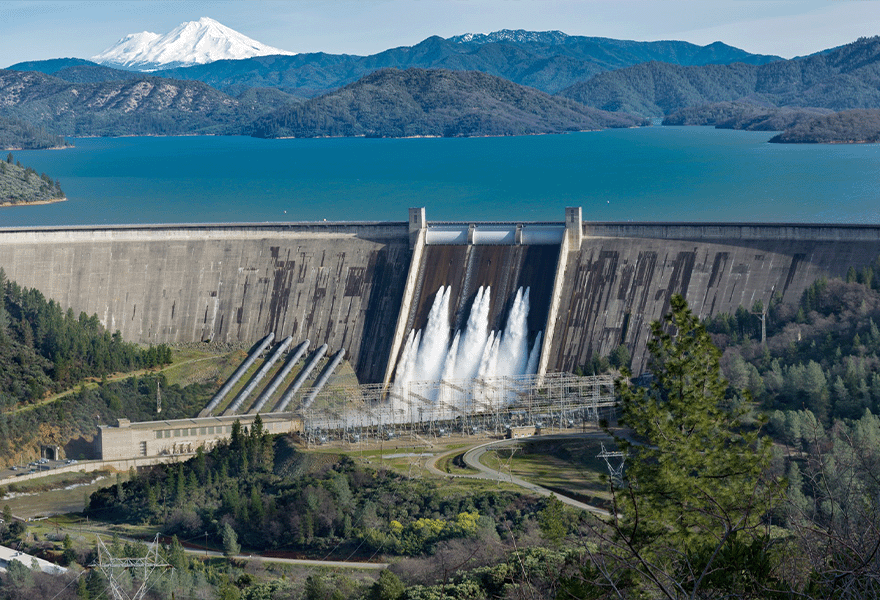

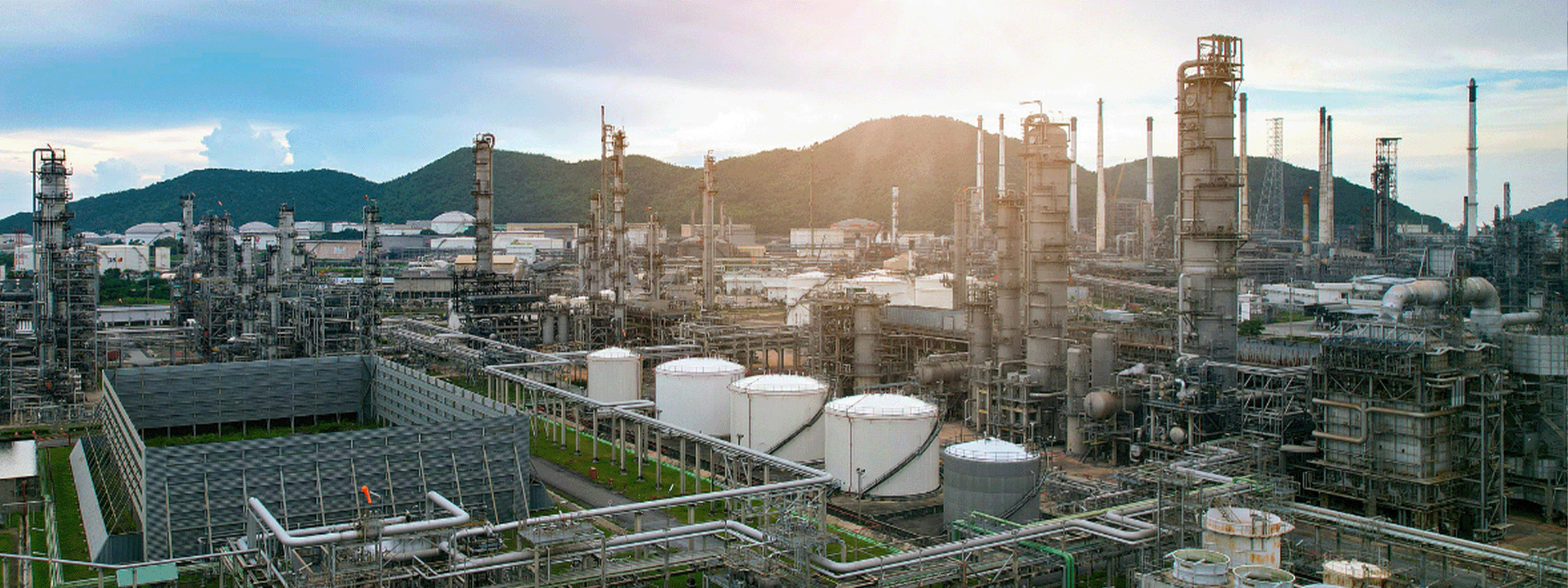

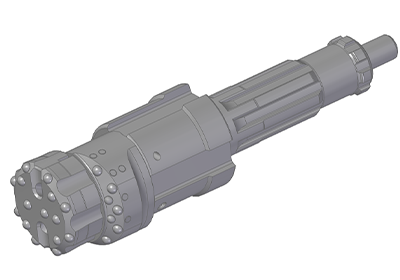

The casing system is a reliable solution for drilling in complex geological conditions, offering significant advantages in various engineering fields. Its versatile design and proven construction processes make it ideal for tough geological environments, including foundation projects, water wells, and geothermal wells. The system is compatible with DTH and top hammer drills, greatly expanding its application.

Casing systems enable large-diameter and deep drilling when combined with heavy construction equipment. They can drill diameters over 1 meter and depths up to several hundred meters, supporting large-scale excavation projects. The system ensures fast drilling speeds, high-quality hole formation, and effective wall support in challenging conditions, preventing drill pipe jamming and debris loss through fractures. This improves debris removal and extends drill bit life.

Depending on the project, the casing can be extracted and reused, reducing costs, or left in place as a permanent anchor. Whether dealing with complex geology or aiming for efficient drilling, casing systems provide solid support for project success.