High Efficiency and Reliability

In the construction industry, where complex and variable soil and rock conditions are common, having reliable rock drilling tools is crucial for ensuring smooth operations in foundation drilling, tunnel excavation, and other construction projects. With extensive industry experience, Kelleg offers high-performance top hammer drilling tools and down-the-hole (DTH) drilling tools designed for construction companies, ensuring versatility, precision, and prolonged service life.

1. Reliable Performance and Strong Adaptability

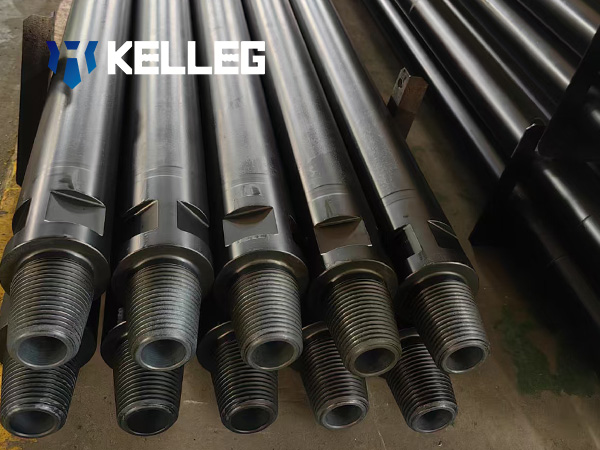

· Durable Materials: Our drilling tools are made from premium-grade carbide and wear-resistant materials, combined with advanced heat treatment technology. It ensures excellent wear resistance and impact toughness, allowing our tools to perform consistently in various soil and rock conditions.

· Adaptability: Specifically designed for construction operations, our tools adapt to different geological formations, ensuring stable performance in complex environments.

2. Versatility and High Precision

·Optimized Drill Bit Design: Our drill bits are engineered for optimal accuracy and efficiency, reducing deviation during operation.

·Multiple Specifications Available: We provide a variety of drilling tool specifications to accommodate various operational needs, from foundation drilling to tunnel excavation, facilitating multi-purpose usage.

3. Extended Service Life and Exceptional Reliability

· Superior Material and Craftsmanship: Using premium materials and advanced manufacturing processes, our drilling tools maintain high accuracy and stability during operation.

· Surface Strengthening Treatment: Each tool undergoes a specialized surface hardening process to enhance corrosion and wear resistance, significantly extending the service life.

· Strict Quality Control: Every product undergoes rigorous factory inspection and quality control to meet the highest industry standards, ensuring maximum service life and reliability.

4. Why Choose Kelleg?

· Professional R&D Team: Our robust research and development team is equipped with advanced facilities, enabling us to tailor drilling tools to meet your specific construction needs.

· Guaranteed Quality: Our products are manufactured and tested strictly by international and industry standards, ensuring outstanding quality and reliability.

· Comprehensive Customer Support: We offer complete pre-sales consultation, on-site guidance, and after-sales service, ensuring our customers receive prompt and professional support throughout the drilling process.

5. Recommended Rock Drilling Tools for Tunnel Construction

Top Hammer Drilling Tools |

|

|

Product |

Details |

|

R32 |

|

|

Button Bit |

R32 Thread, 48mm, Spherical buttons, 6 Gauge buttons |

|

R32 Thread, 51mm, Spherical buttons, 6 Gauge buttons |

|

|

R32 Thread, 57mm, Spherical buttons, 6 Gauge buttons |

|

|

R32 Thread, 64mm, Spherical buttons, 8 Gauge buttons |

|

|

MF Rod |

T38-R32 Thread, Length 4305mm, Hexagonal rod |

|

R38-R32 Thread, Length 4915mm, Hexagonal rod |

|

|

T38-R32 Thread, Length 5525mm, Hexagonal rod |

|

|

R38-R32 Thread, Length 6400mm, Hexagonal rod |

|

|

Coupling Sleeve |

R38-R38 Thread, Length 190mm, Semi-bridge type |

|

T38-T38 Thread, Length 190mm, Full-bridge type |

|

DTH Drilling Tools |

| Our company's down-the-hole drilling tools can achieve a low-pressure drilling diameter of 70~250mm; medium-high pressure drilling diameter of 90~254mm. Other drilling diameters can also be customized. |

Choosing Kelleg's rock drilling tool solutions means gaining access to high-performance, versatile, highly precise, and long-lasting drilling tools. We are committed to being your trusted partner in construction projects, helping you overcome various challenges, and ensuring the successful completion of your projects.