Introduction

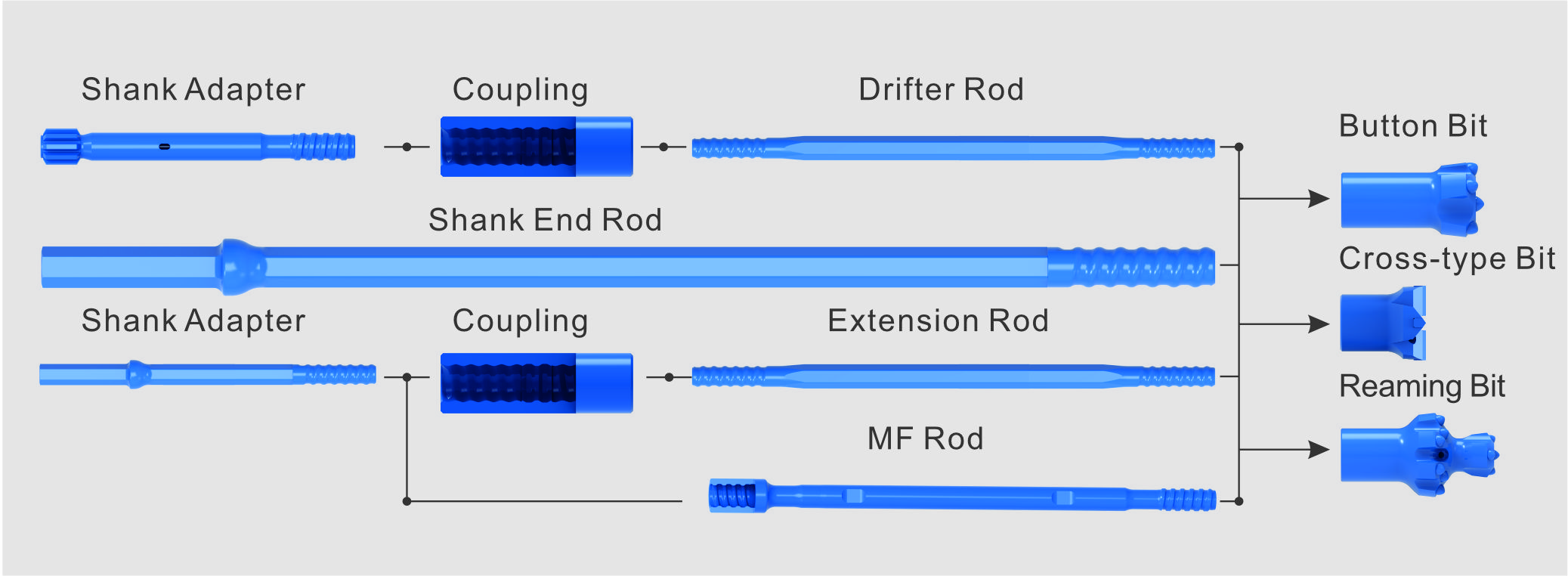

Top hammer rock drilling tools are designed for efficient operations in mining, tunnel construction, and other engineering projects. The tool set includes a rock drill bit, drill rod, shank adapter, and coupling sleeve.

· The rock drill bit is made of high-hardness alloy, offering strong wear resistance and high efficiency in breaking hard rocks, reducing replacement frequency and operational costs.

· The drill rods are forged for excellent fatigue strength and toughness, ensuring stable energy transmission and smooth operation under high-frequency impacts.

· The shank adapter ensures efficient power transfer by fitting perfectly with the rock drill.

· The coupling sleeve securely connects all parts for seamless operation.

In short, top hammer drilling tools deliver superior performance, improving both efficiency and stability, and ensuring the quality of your project. Choose these tools for an efficient, cost-effective, and reliable drilling solution.