High Efficiency & Durability

In the oil and gas drilling industry, where the extreme pressures and temperatures of deep and complex rock formations make it essential to have efficient and durable rock drilling tools, Kelleg, with its many years of experience and know-how in the industry, offers oil and gas drilling companies highly efficient solutions for top hammer rock drilling and DTH drilling tools, which are designed to meet the demanding requirements for tool performance and durability in extreme drilling conditions. We have developed highly effective solutions for oil and gas drilling companies.

1. Superior Adaptability to Extreme Environments

· High-strength, high-toughness carbide inserts, and wear-resistant materials, combined with advanced heat treatment processes, ensure that the drilling tools maintain excellent wear resistance and impact strength even under extreme pressure and temperature conditions.

· Designed for deep and complex rock formations, it can easily cope with rocks of various hardnesses and densities to ensure smooth drilling operations.

2. Enhanced Durability

· Optimized rock drill bit design and cutting structure reduces friction and wear between the rock drill bit and rock, significantly extending the service life of the drilling tools.

· Surface hardening treatments are applied to enhance the corrosion and wear resistance, ensuring long-term tool performance.

· Every drilling tool undergoes rigorous quality control and factory testing to meet the highest industry standards, ensuring reliable performance under harsh drilling conditions.

3. Improved Drilling Efficiency

· The structural design of the drilling tools is optimized to enhance operational safety and increase drilling efficiency.

· Provides customized rock drilling tool solutions, adapting bit shapes and sizes to specific drilling needs for optimal drilling results.

· We offer professional drilling guidance and technical support to help customers maximize the performance of their drilling tools in actual operations.

4. Why Choose Kelleg?

· Customized Solutions: Our strong R&D team and advanced production facilities enable us to provide tailor-made drilling tool designs that perfectly match your drilling needs and site conditions.

· Quality Assurance: We strictly adhere to international and industry standards for production and testing, ensuring that every product meets the highest quality requirements for safe and efficient use.

· Technical Support: We offer extensive technical support and after-sales services, including on-site guidance, operator training, and maintenance of equipment, to ensure that our customers maximize the use of their drilling tools.

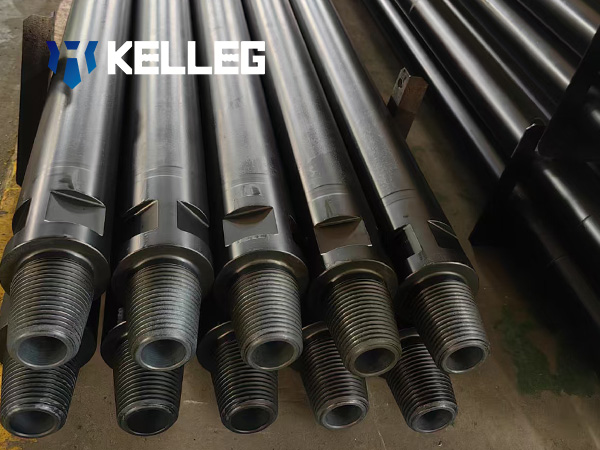

5. Commonly Used Rock Drilling Tools in Oil and Gas Drilling

DTH Drilling Tools |

|

Our company's down-the-hole drilling tools can achieve a low-pressure drilling diameter of 70~250mm; medium-high pressure drilling diameter of 90~254mm. Other drilling diameters can also be customized. |

Choosing Kelleg's rock drilling tool solutions means equipping yourself with reliable tools capable of drilling through deep, complex rock formations under extreme pressure and temperature conditions. We are committed to providing you with high-durability, high-efficiency drilling tools that help maximize productivity and ensure outstanding results in your oil and gas drilling operations.