Application of Air DTH Hammer Drilling Technology in Ventilation Shaft Construction for a Gold Mine

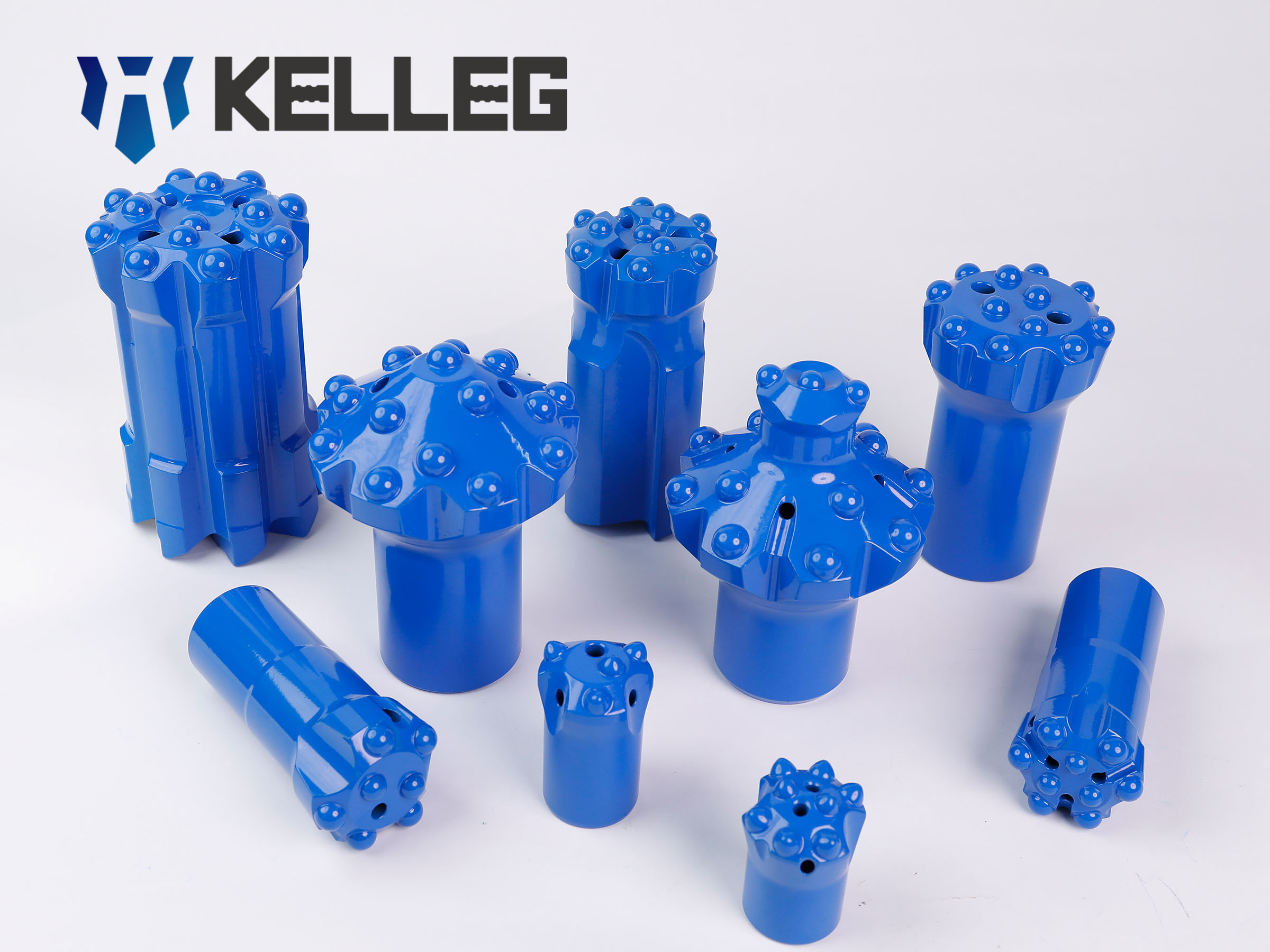

Air DTH hammer drilling improved ventilation hole efficiency in a gold mine, reducing costs and ensuring borehole quality under complex geology.

Know More