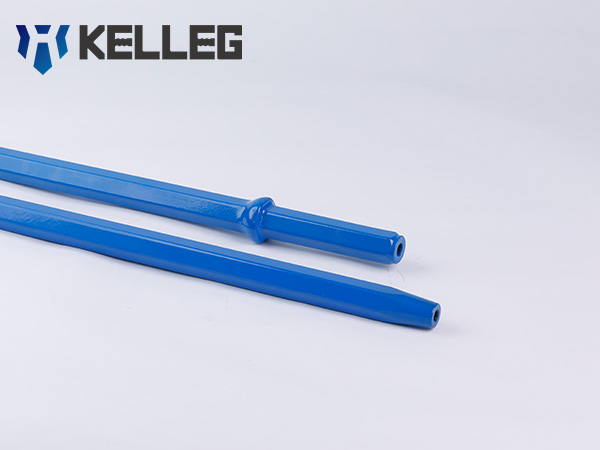

The drill rod is the core carrier for transmitting energy in rock drilling operations. It needs to connect the drill bit and work with rock-drilling machinery, enabling the rock drill to conduct drilling operations in rocks. Every size of the drill rod directly impacts the performance of the entire rock-drilling system. An appropriate diameter allows for the loss-free transmission of impact energy; an accurate length ensures precise control of the drilling depth; an optimized thread design guarantees reliable connections; and the choice of drill rod material is directly related to its impact resistance and durability.

This seemingly simple size determines rock-drilling operations'efficiency, accuracy, and safety . Therefore, in-depth research on the dimensional design of drill rods is of great practical value for improving rock-drilling efficiency, reducing energy consumption, and extending the service life of equipment.

First, let us understand the size requirements of the drill rod.

Four size requirements

Length

The length of the drill rod is determined by the length of the drilling rig of the feed beam. It should ensure the stability of the connection and ease of operation. Generally speaking, the drill rod length should be within the requirements of the connecting equipment. Too long a drill rod may cause instability during rotation and increase the risk of bending or breaking, especially when drilling in hard rock. On the other hand, shortening a drill rod may limit the drilling depth and affect the overall efficiency of the rock-drilling operation.

Diameter

The diameter of the drill rod directly affects its strength and stability. A proper drill rod diameter allows the rod to rotate freely and maintain a reasonable annular clearance for effective slag removal. An overly large annular clearance may lead to inefficient use of flushing fluid and reduced slag-removal efficiency, while too small one can easily cause slag accumulation and even cause jamming of the drill rod. In addition, the small diameter may cause the rod to bend or break easily under the impact load, while the large diameter may increase the consumption of raw materials and the weight of the equipment. Therefore, it is necessary to combine and consider the actual needs.

Material

The material of the drill rod has an important influence on its dimensional stability, corrosion resistance, and wear resistance. Choosing the appropriate material can ensure the dimensional accuracy of the drill rod and extend its service life. Different materials have different mechanical properties. Some special materials also have good corrosion resistance and are suitable for use in wet or corrosive rock drilling environments.

Tread Design

The thread dimensions of a drill rod are of utmost significance as they play a pivotal role in the overall performance of the rod during rock-drilling operations. Besides the thread at the shank adapter, the thread on the drill rod itself demands meticulous design in terms of its dimensions. When it comes to the thread at the drill bit, its dimensions need to be carefully determined based on the above-mentioned factors. It must be compatible with the drill bit size and type to ensure a secure connection and efficient power transfer from the drill rod to the drill bit. A well-designed drill bit thread with appropriate dimensions can improve the stability of the drill bit during operation, reduce the risk of bit breakage or detachment, and ultimately enhance the overall drilling performance.

Factors Influencing Drill Rod Size

After clarifying the four size requirements for drill rod selection, it is necessary to focus on the following key influencing factors:

Environment

A multitude of environmental factors, such as temperature, humidity, and corrosive media, can exert significant impacts on the drill rod.

Humidity, for instance, poses a considerable threat to the drill rod. In humid conditions, airborne moisture reacts with the drill rod's metal surface, triggering rust formation. Rust not only deteriorates the appearance of the drill rod but also weakens its structural integrity. In extreme cases, rust can even lead to the breakage of the drill rod during operation, resulting in costly downtime and potential safety hazards.

Corrosive media present another challenge. These corrosive agents can react with the material of the drill rod, gradually eating away at it. Similar to rust, corrosion can compromise the strength and dimensional stability of the drill rod. It may cause the drill rod to become thinner in some areas, leading to uneven stress distribution and an increased risk of failure.

Temperature

Temperature also plays a crucial role. In a high-temperature environment, the drill rod will expand due to thermal expansion. This expansion can cause several problems. Firstly, it may affect the fit and alignment of the drill rod within the drilling equipment. Secondly, the dimensional accuracy of the drill rod is reduced. In applications where precise drilling is required, this loss of accuracy can be unacceptable. On the other hand, in a low-temperature environment, the drill rod will contract. This contraction can affect the stability of the connection between the drill rod and other components. Loose connections can result in inefficient power transfer, vibrations, and potential damage to the drill rod and the associated equipment.

Working pressure

Changes in operating pressure are yet another important factor that can cause dimensional changes in the drill rod. When the drill rod is subjected to high pressure, it may undergo plastic deformation. This deformation can not only affect the performance of the drill rod but also pose safety risks. A bent drill rod may be more prone to breaking during operation, and a reduced diameter can weaken its load-bearing capacity.

On the other hand, under low-pressure conditions, the drill rod may elastically recover. To ensure the reliable operation of the drill rod under varying working pressures, proper material selection, design optimization, and regular inspection and maintenance are essential.

Measures for maintaining the size of the drill rod

To maintain the size stability of the drill rod, the following targeted protective measures should be focused on.

Corrosion Resistance: Apply protective coatings to protect against moisture and corrosive media.

Humidity Control: Implement humidity-controlled storage environments for drill rods to prevent rust. Regularly inspect and clean drill rods to remove corrosive residues.

Pressure Monitoring: Install sensors to track real-time working pressure and avoid overloading. Regularly check for plastic deformation.

Routine Inspection: Regularly inspect the surfaces of drill rods for corrosion, wear, or cracks. Apply anti-corrosive lubricants to threaded connections to reduce friction and prevent oxidation.

After understanding the drill rod size requirements, influencing factors, and solutions, in order to have a deeper understanding of the importance of drill rod size, let us explore the method of drill rod measurement.

Size measuring method

There are three main methods for measuring the size of drill rods: direct measurement, indirect measurement, and digital measurement.

Direct measurement

Direct measurement is a fundamental and straightforward approach to obtaining the dimensions of drill rods. In practical operations, the drill rod, which is an essential component in the realm of rock drilling tools, needs to be precisely positioned within specific measuring instruments.

Since the entire operation relies heavily on human hands, it is prone to human-induced errors. Variations in measurement techniques and reading habits among different operators can lead to discrepancies in the measurement results. Moreover, for drill rods with complex structures, direct measurement may not be able to accurately capture all the dimensional information comprehensively.

Indirect measurement

Indirect measurement is primarily employed for drill rods with complex shapes that are difficult to measure directly. Instead of directly reading the dimensions of the drill rod, this method involves measuring other parameters related to its size, such as weight and volume. Then, based on pre-established formulas and known material properties, the dimensions of the drill rod are calculated.

The accuracy of indirect measurement depends significantly on the accuracy of the selected calculation formulas and the precision of the measured parameters. Even a minor error in the input parameters can be magnified during the calculation process, resulting in a significant deviation between the calculated dimensions and the actual ones.

Digital measurement

Digital measurement represents a high-precision measurement approach that combines modern computer technology and advanced sensor technology. During the measurement process, sensors placed at key positions around the drill rod continuously collect various data, such as its outer contour and surface features. These data are then promptly transmitted to a computer system, where specialized measurement software processes and analyzes them.

Moreover, digital measurement offers the advantages of high efficiency and automation. It significantly reduces human-induced errors and labor intensity, thereby improving the efficiency of measurement and the level of quality control.

However, the high cost of research, acquisition, and maintenance of digital measurement equipment can be a significant financial burden for some enterprises with limited budgets.

Conclusion

The importance of the size of the drill rod is self-evident. The accuracy and stability of its size are directly related to the performance and safety of the equipment. In practical applications, many factors may affect the drill rod size. Therefore, the design of drill rods should fully consider these factors and take appropriate measures to minimize their effects. At the same time, using appropriate measurement methods is also the key to ensuring the dimensional accuracy of the drill rod.