In mining engineering, rock drilling is a fundamental operation that critically governs construction progress, structural integrity, occupational safety, and project budgeting. To address diverse geological conditions and operational objectives, construction sites deploy specialized rock drilling systems comprising multiple coordinated components. These purpose-engineered tools are collectively referred to as rock drilling tools. What exactly are rock drilling tools?

This article will provide a detailed introduction to rock drilling tools from four key dimensions: meaning, classification, components, and applications. Before delving into the specifics of rock drilling tools, it is essential to first explore their significance in drilling operations. Let us begin by exploring the Importance of Rock Drilling Tools.

Understanding the Importance of Rock Drilling Tools

Rock drilling tools are indispensable in industries such as construction, mining, and geological exploration. Their significance can be emphasized through the following key aspects:

A. Efficiency and Productivity

Speed: High-quality rock drilling tools significantly enhance drilling speed, reducing project timelines.

Precision: Accurate drilling minimizes errors and the need for rework, optimizing resource utilization.

B. Cost-Effectiveness

Durability: Durable tools reduce the frequency of replacements, offering long-term cost savings.

Reduced Downtime: Reliable tools decrease equipment failures and downtime, boosting productivity and lowering operational costs.

C. Safety

Reliability: High-quality tools are less prone to failure, reducing the risk of accidents and injuries.

Reasonable Design: Well-designed tools ensure safer operations, protecting workers from potential hazards.

D. Quality of Work

Consistency: Reliable rock drilling tools deliver consistent performance, ensuring high-quality results in construction and mining projects.

Accuracy: Trustworthy tools enhance alignment and fit, which are critical for structural integrity and resource extraction.

By understanding the importance of rock drilling tools, industries can make informed decisions to improve efficiency, safety, and overall project outcomes. At the same time, understanding the importance of rock drilling tools will help you understand their specific meaning in more depth. Next, we will get to the point and discuss the meaning of rock drilling tools in detail.

Classification of rock drilling tools

A. Top hammer rock drilling Tools

The top hammer impact rock drilling is that the rock drilling machine is located at the top of the rock drilling tool, and the rock drill piston directly hits the rear end of the rock drilling tool, and the impact energy generated is in the form of stress wave through the rod body to reach the drill bit to do work on the rock. The rock drilling machine uses compressed gas or hydraulic oil as the power source, and the impact power can be designed according to the requirements of the equipment, so it has a higher rock drilling rate. It can be mainly divided into rock drilling tools for light rock drills, rock drilling tools for underground mining, rock drillingtools for rock drilling and excavation, and rock drilling tools for full hydraulic open-pit rock drilling rigs.

B. Down-the-hole rock drilling tools

Different from the top hammer type rock drilling tool, the down-the-hole type rock drilling tool is a medium and large-diameter rock drilling machine that uses compressed air as the power source to enter the power part into the rock hole for rock drilling. The application of external rock drilling engineering is very extensive. Down-the-hole rock drilling tools are usually composed of three parts: a DTH hammer, a DTH drill bit and a drill pipe, which are equipped on a drilling rig (drill stand) and equipped with an air compressor to form a rock drilling unit. According to the pressure of the compressed air used by DTH drilling tools, it is usually divided into low-pressure DTH drilling tools (pressure 0.6-0.8MPa), medium and high-pressure DTH drilling tools (pressure 1.0-2.0MPa).

C. Mining roller cone rock drilling tools

Mining roller cone drilling tools are mainly used for vertical perforation operations in large-scale open-pit mines, earth-rock excavation, water wells, and geothermal wells. During the drilling process, the roller cone rock drilling drives the roller cone bit to rotate through the drill rod, and at the same time applies downward thrust to penetrate the hole. Under the rotational force, the roller cone rock drilling drives three roller cones with carbide teeth or steel teeth to rotate around their respective claw journals, and at the same time, under the action of axial thrust, the carbide teeth or steel teeth It is embedded in the rock surface, and the rock is broken by the combined force of extrusion and shearing, so as to achieve the purpose of perforation.

D. (Reverse) Raise drilling tools

The rock drill bit of the raise drilling tool is composed of a rolling scraping bit and a bracket inlaid with cemented carbide teeth, and the drilled hole diameter ranges from φ500 mm to 6000 mm.

E. Drilling tools for geological exploration

Geological exploration drilling tools are a type of rock drilling tools. Some well-known rock drilling tool manufacturers have their own complete production systems for geological exploration drilling tools.

F. Mechanical cutting drilling tools

The mechanical cutting and drilling process is a non-drilling and blasting construction technology that uses the power generated by the drilling machine to drive the drilling tools to cut the rock and soil to complete the drilling and excavation construction. They are mainly divided into trenchless engineering drilling tools, shearer picks, pavement cold milling machine picks, tunnel excavation shield machine tools, slotting machine picks, and road grader picks.

The aforementioned categorization framework corresponds to the operational classifications of rock drilling machinery in geotechnical drilling and excavation engineering. In consideration of the prevalent application of top hammer rock drilling tools within industry practices, the following section will introduce the composition of top hammer rock drilling tools.

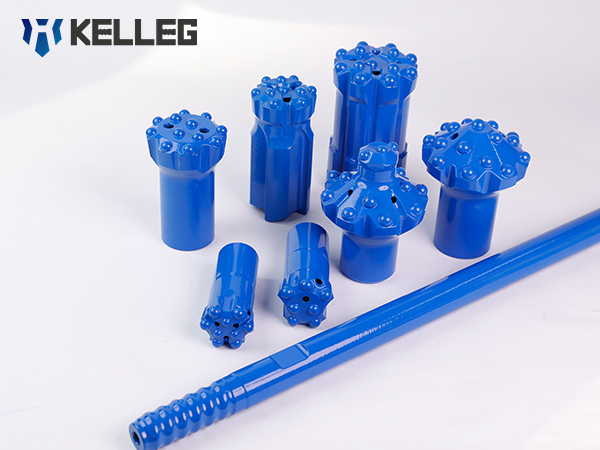

Composition of top hammer rock drilling tools

A. Rock drill bit

The rock drill bit is an indispensable tool in the field of drilling. According to different operation and construction requirements, the drill bit has different classification methods. According to the shape of the rock drilling alloy, the drill bit can be divided into a sheet drill bit, button bit, and Chip-tooth composite drill bit, Sheet Drill Bit: in-line type, three-blade type, cross type/X type, The application of different rock drill bits varies.

B. Drill rod

Drill rods are tools used to connect the rock drill bits to drilling equipment for rock or soil excavation. The drill rod also has different classifications, such as integral drill rod, tapered drill rod, shank rod, extension rod,me rod etc.

C. Coupling sleeve

The coupling sleeve is used to connect the drill rod and the drill rod, connect the drill rod and the shank adapter, and has a sleeve with internal thread.

D. Drill adapter

Can be a separate interface device, connected to the drill bit.coupling sleeve

E. Shank adapter

The shank adapter is a component that connects one end to the rock drill and the other end to the drill rod. Its primary function is to directly bear the impact energy and torque from the rock drill. During the drilling process, the shank adapter transfers the energy from the rock drill to the drill rod and drill bit, enabling the rock to be fractured.

Rock drilling serves as a foundational technology across diverse engineering disciplines, with operational methodologies spanning percussive, rotary, and hybrid drilling systems. As critical enablers of subsurface operations, rock drilling tools constitute the industry's technological focal point due to their direct impact on operational efficiency and project economics. What are their specific applications in the field of rock drilling?

The application of rock drilling tools

A. Hand-held rock drilling

Hand-held rock drilling is rock drilling performed with a hand-held light rock drill. It is mainly used in small construction sites or environments where larger equipment cannot be used in limited space.

B. Mechanical rock drilling

In mechanical rock drilling, operators often monitor two or three rock drills. Rock drills are mounted on thrusters or glide arms. Equipment that carries pushers or sliding arms for mechanized rock drilling is called a drilling rig.

C. Terrace rock drilling

Terrace rock drilling is a mining method in which blasting holes are drilled on terraces for terrace blasting. It is a relatively simple way of rock drilling.

D. Rock drilling for level road excavation

Rock drilling is a rock drilling operation method for blasting rock holes in tunnels or air-raid shelters.

E. Production of rock drilling (medium and deep holes)

Production rock drilling refers to the drilling of blasting rock holes in an ore body or the extraction of production rock in a quarry. Therefore, this rock drilling method is suitable for open pit mines, quarries, and underground mines. Usually for deep-hole drilling or terrace mining.

F. Support rock drilling

Support rock drilling is used to prevent roadway and rock from slumping. First, a rock hole is drilled in the rock, and then the expansion bolt or grouting bolt is installed. The bolt reinforces the surrounding rock that may loosen and fall off.

G. Lifting and drilling rock

Vertical phase channels are often required in wells or other underground shelters. The vertical channel can now be drilled over the entire face using the lift-drilling method.

H. Overload rock drilling

When drilling foundation pile holes, anchor holes, or water well holes (sometimes also used for blasting work holes), it may be more advantageous to use the overload rock drilling method.

Key Factors in Selecting Appropriate Rock Drilling Tools

In various rock drilling projects, choosing the right rock drilling tools is crucial for ensuring the smooth progress of the project, improving work efficiency, and controlling costs. The following are the key factors that need to be carefully considered when selecting rock drilling tools:

A. Rock Type and Hardness

Rock type and hardness serve as the fundamental basis for selecting rock drilling tools. Different rock types and hardness levels have vastly different requirements for tool wear resistance and cutting performance.

B. Drilling Methods

The choice of drilling method directly determines the type of applicable rock drilling tools.Down-the-Hole drilling is commonly used for large-diameter and deep-hole drilling operations. In this case, down-the-hole drilling tools are required, including down-the-hole drill bits, down-the-hole hammers, and the matching drill pipes. Rotary drilling is generally used for drilling in soft or medium-hard rocks. The drill bits cut the rock through high-speed rotation and can achieve efficient cutting and slag removal during the rotation process due to their structural features.

C. Operational Efficiency and Cost Considerations

Operational efficiency and cost are non-negligible important factors when selecting rock drilling tools. High-efficiency rock drilling tools can shorten the operation time and accelerate the overall project progress. Therefore, when making a selection, a comprehensive trade-off should be made to choose tools with high cost-effectiveness.

D. Durability

Durability is a key indicator for measuring the quality and performance of rock drilling tools. In the harsh rock drilling environment, tools need to withstand significant pressure, friction, and impact. Therefore, good durability is essential to ensure stable operation. Rock drilling tools with high durability can not only reduce the time and cost losses caused by frequent tool replacements but also ensure the continuity and stability of the operation process, which is of great significance for improving project quality and efficiency.

Conclusion

As critical auxiliary components for rock drilling equipment systems, rock drilling tools demonstrate comprehensive product specifications, diversified configurations, and are suitable for various scenarios.

Companies who are interested in this or have related product requirements can continue to pay attention and contact us.Kelleg will be happy to provide you with high-quality products and services.