In complex underground construction projects, layers of large-grained gravel have long been regarded as a significant challenge by construction teams. This geological layer, characterized by large particles, high permeability, and instability, often results in low efficiency and high costs when using traditional drilling techniques and may even fail to meet project requirements. However, with advances in technology, the Down-the-Hole (DTH) hammer has emerged as an efficient and reliable drilling tool. Its unique impact mechanism and effective cuttings discharge make it well-suited for penetrating large-grain pebble layers, offering a high-performance solution in complex geological conditions.

So, how exactly does the DTH hammer manage to drill efficiently in such difficult formations?

Challenges of Large-Grain Pebble Layers

Large-grain pebble layers consist of coarse, unevenly distributed pebbles and pose several specific challenges:

Large particle size: Oversized pebbles increase the difficulty of breaking and penetrating the formation.

High permeability: The gaps between pebbles allow water to seep through easily, introducing additional uncertainty.

Poor stability: The loose structure makes the layer prone to displacement or collapse, compromising safety.

In the face of these challenges, traditional drilling methods such as rotary drilling and percussion drilling are often inefficient, costly, and even unable to complete drilling tasks. Therefore, finding an efficient and reliable drilling technology has become a matter of urgency.

Working Principle of the DTH Hammer

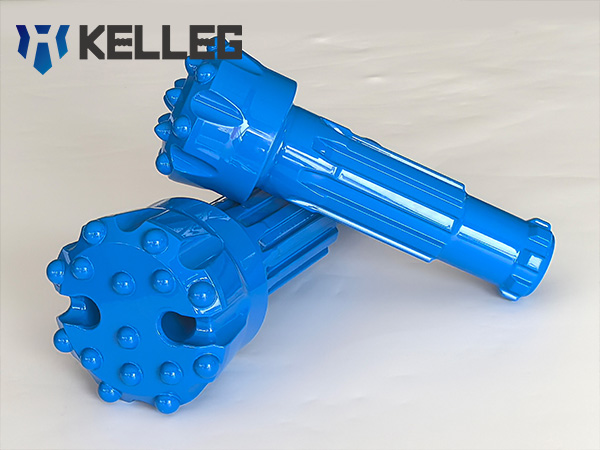

The DTH hammer is a pneumatic rock drilling tool powered by compressed air. High-pressure air enters the hammer through the drill rig’s air valve and travels down the drill rod. The airflow is divided by a valve system: one path directs air to the bottom of the hole to flush out cuttings, while the other activates the piston within the hammer. The piston strikes the drill bit with high-frequency impacts, breaking the rock. Simultaneously, air or drilling fluid removes debris and cools the tool, allowing continuous and efficient drilling.

Advantages in Large-Grain Pebble Layers

1. High-impact fragmentation

DTH hammers deliver high-frequency impacts directly onto the rock or pebbles, efficiently breaking large particles. Compared with rotary drilling, they are more effective in fracturing hard, oversized aggregates.

2. Powerful cuttings discharge

Using compressed air as a flushing medium, DTH hammers effectively remove debris from the hole. It is especially critical in permeable and collapse-prone formations where poor cleaning can cause stuck pipes or borehole deviation.

3. Strong adaptability

DTH hammers can be tuned—by adjusting impact frequency, rotation speed, and air pressure—to suit different rock sizes and hardness levels. This flexibility ensures consistent performance in highly variable geological conditions.

Application of DTH Hammers in Large-Grain Pebble Layers

Pre-drilling Preparation

Geological survey: Collect detailed data on pebble distribution, thickness, size, and hardness to inform equipment selection and parameter settings.

Equipment selection: Based on the results of geological surveys, select the appropriate model of down-the-hole hammers and supporting equipment, such as air compressors, drill rods, and drill bits.

Parameter setup: Based on the characteristics of the gravel layer, set reasonable parameters such as drilling pressure, rotation speed, air pressure, and air supply volume to ensure efficiency and safety during the drilling process.

Drilling Process Control

Low-speed startup: Begin drilling at low speed and gradually increase pressure and rotation to avoid sudden shocks that can cause jamming or deviation.

Real-time monitoring: Assign a dedicated person to closely monitor the sinking of the drill string and the debris removal inside the hole. If any abnormalities are detected, adjust the parameters or take other measures.

Adaptive adjustments: When encountering large-diameter pebbles or hard gravel, adjust the rotation speed and drilling scale of the drill bit to avoid forcing it forward, which could result in equipment damage or accidents inside the hole.

Borehole Cleaning and Casing Support

Collar cleaning: Keep the borehole collar clear of accumulated cuttings to maintain a safe and efficient worksite.

Casing advancement: Use casing while drilling to support the borehole wall, prevent collapse, and ensure hole integrity.

Key Factors for Efficient Drilling

1. Optimize Drilling Parameters

Drilling pressure: Controlling drilling pressure is key to ensuring close contact between the drill bit and the rock layer. In large-grained gravel layers, drilling pressure requires adjustment based on actual geological conditions, typically maintained around 60–80 kN. However, specific values must be flexibly adjusted according to on-site conditions to ensure efficient drill bit operation without causing kickback.

Rotation speed: Use a lower speed (15–20 rpm) in hard pebble layers to reduce bit wear and avoid tool disengagement.

Air pressure: Typically set at 0.8–1.0 MPa, based on bit type and formation hardness.

Air volume: The airflow must be sufficiently strong to ensure that debris and rock fragments inside the hole are blown to the ground. The airflow is generally between 8 and 12 m³/min, with the specific value adjusted according to the depth of the hole and the amount of debris.

2. Use Casing-While-Drilling Technique

This technique allows the casing to advance simultaneously with the drilling, achieving single-pass completion and preventing wall collapse—essential for stability in loose pebble layers.

3. Real-Time Strategy Adjustment

Drilling strategies must adapt to real-time conditions. For example, in extremely hard sections, reduce feed pressure and rotation speed to avoid tool jamming or borehole deviation. Constant supervision is critical.

4. Focus on Cuttings Removal and Borehole Support

Debris removal is an indispensable part of the drilling process. The compressed air generated by the down-the-hole hammer is not only used to drive the drill bit to break up pebbles but also serves as a washing medium to remove broken rock debris from the hole and accumulate it at the hole mouth. Therefore, it is necessary to assign dedicated personnel to promptly clear the rock debris at the hole mouth to ensure the safety and efficiency of the work site. At the same time, attention should be paid to wall protection measures, such as using casing for wall protection, to prevent adverse situations, such as hole collapse.

Conclusion

With its powerful impact force, adjustable parameters, and efficient cuttings removal, the DTH hammer excels in drilling through large-grain pebble layers. It not only boosts drilling speed and lowers operational costs but also enhances safety and hole quality. As DTH technology continues to evolve and its applications expand, it is poised to play an even greater role in overcoming complex geological challenges and advancing underground construction.