Casing systems are used for drilling in hard, loose, fractured, or gravel-rich formations where simultaneous casing advancement is required. These tools allow for drilling while advancing the casing or pre-advancing the casing before continuing drilling, effectively preventing borehole collapse and sand inflow. This method ensures excellent borehole stability and high drilling efficiency.

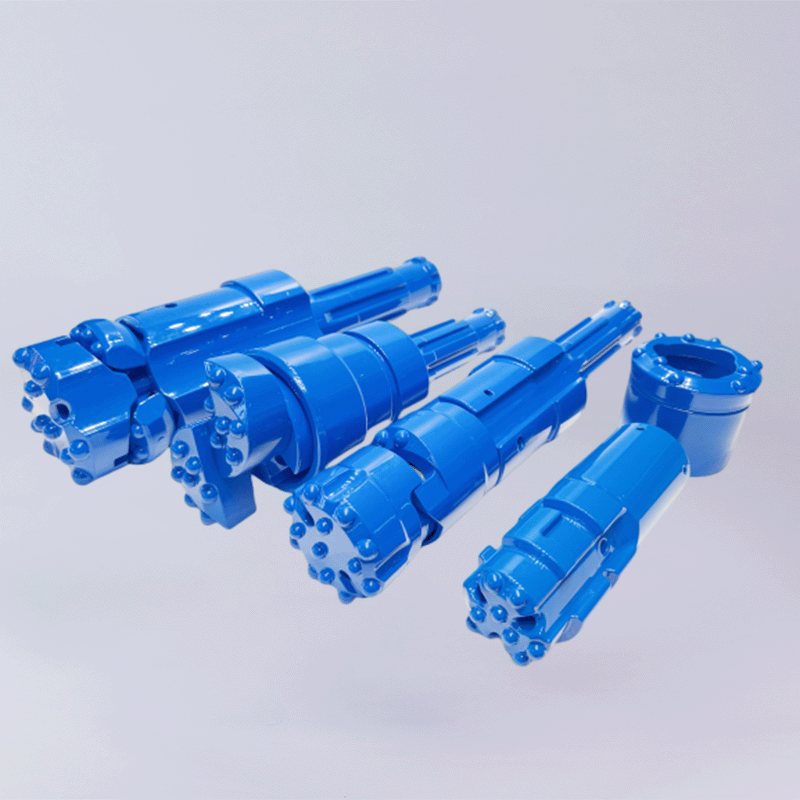

Types of Casing Systems

Classified by Drilling Equipment

| Type | Composition | Application |

| Top hammer casing systems | casing drill bit + casing shoe + casing + coupling (Note: MF casing needn't coupling) + drill pipe (including a coupling sleeve) + centralizer, etc. | It is mostly used for small and medium-sized shallow hole construction with a hole diameter of φ90-150mm and a hole depth of fewer than 30 meters. |

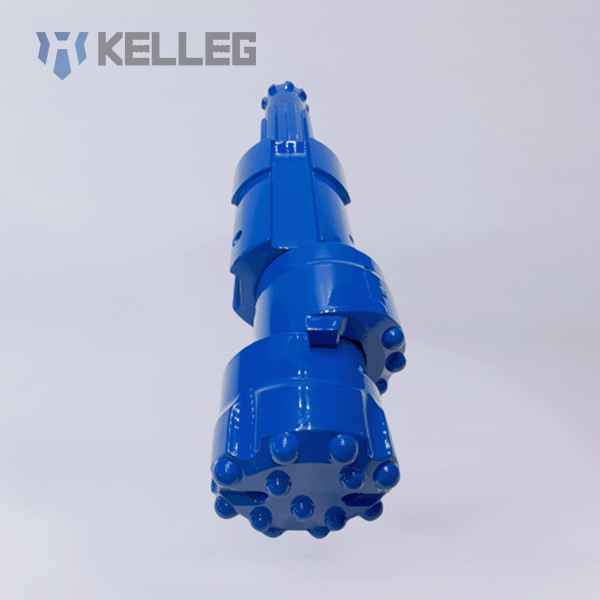

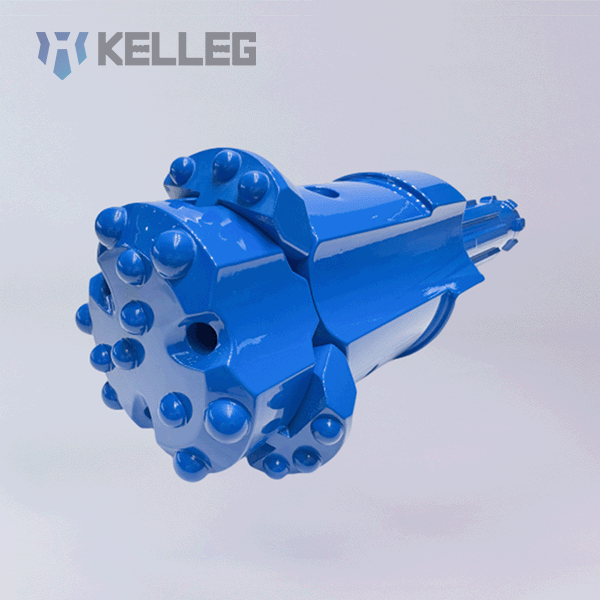

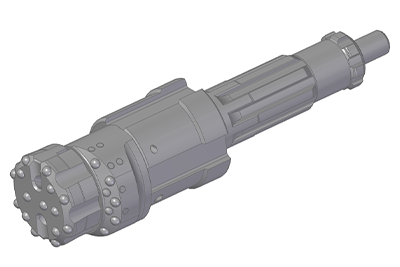

| DTH casing systems | casing drill bit + casing shoe + casing + coupling (note: MF casing needn't coupling) + DTH hammer + drill pipe + centralizer, etc. | It is commonly used for borehole diameters ranging from φ600mm to φ800mm (though the exact range may vary depending on the drill bit and geological conditions) and borehole depths between 40m and 80m. |

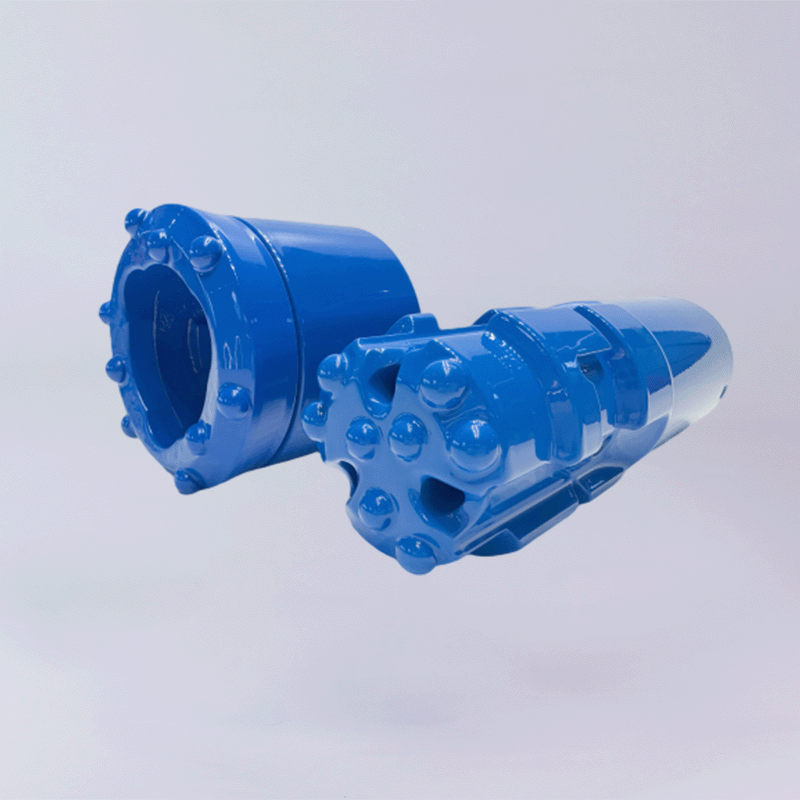

Classification by Drill Bit Structure

| Type | Applicable Geology | Scope of Work | Application |

| Eccentric casing system | It is suitable for covering layers with mostly loose materials on the surface of the formation, such as soil, clay, weathered rock, sand and gravel, etc. | It is suitable for drilling geothermal wells, water wells, small and medium-sized grouting holes for construction, mini-piles, etc. | It is suitable for small to medium-diameter (≤350mm) water wells, geothermal wells, and other shallow borehole (≤40m) projects, though it has relatively poor borehole straightness. |

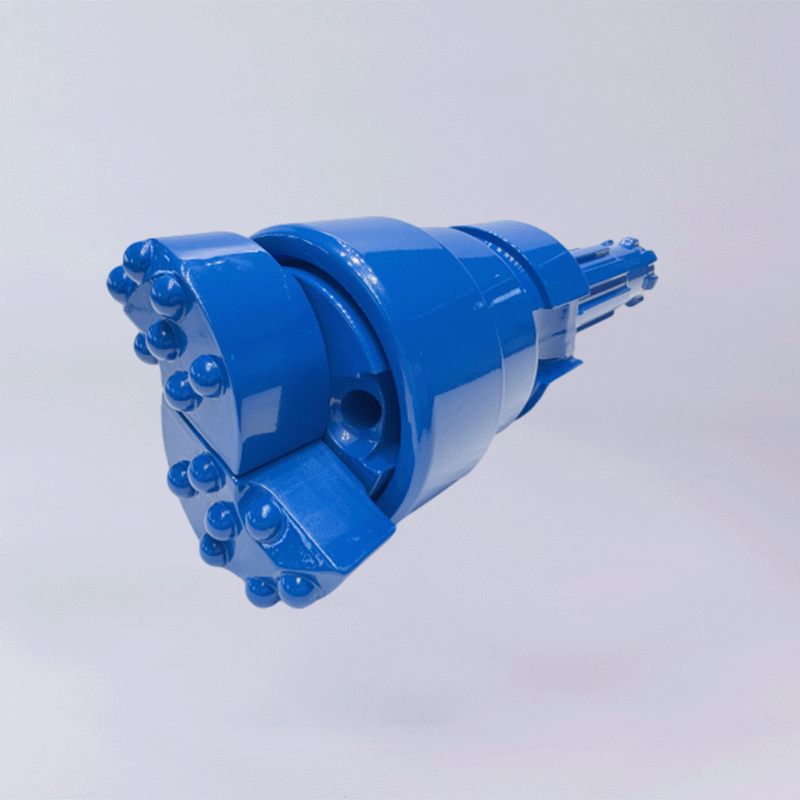

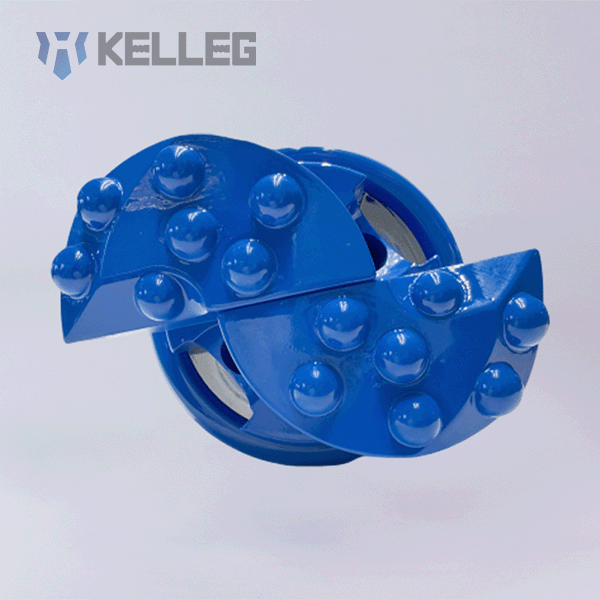

| Symmetric casing system with reamer | It is suitable for covering layers with complex geological conditions, such as pebble layers, cracks, boulders, construction backfills, etc. | It is mainly used for pile foundation and anchoring projects. | Provides stable drilling, low noise, and excellent borehole straightness, making it ideal for large-diameter, medium to deep boreholes. |

| Symmetric casing system with wings | It is suitable for covering layers with mostly loose materials on the surface of the formation, such as soil, clay, weathered rock, sand and gravel, etc. | It is suitable for drilling geothermal wells, water wells, small and medium-sized grouting holes in buildings, micro piles, etc. | Ensures even drilling force and excellent borehole straightness, making it suitable for construction with diameters up to φ600mm. |

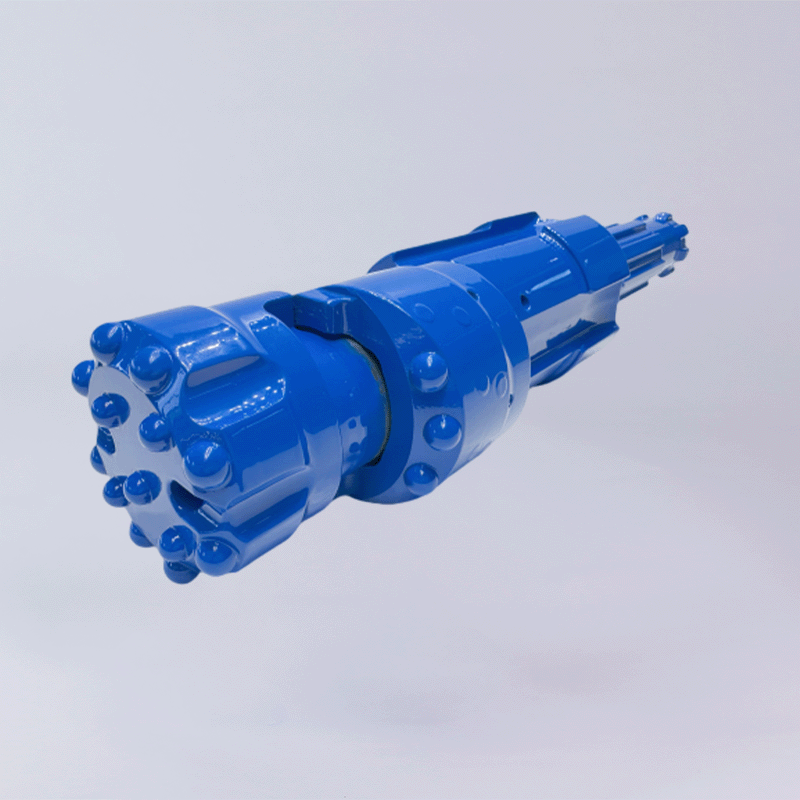

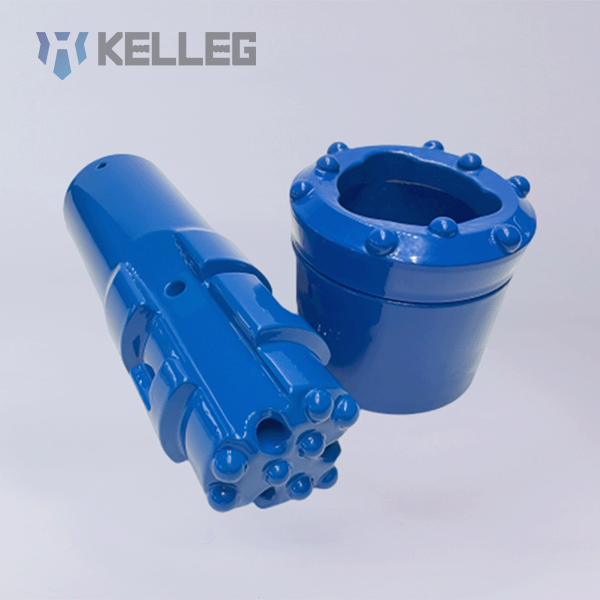

| Symmetric casing system with slide blocks | It is suitable for covering layers with mostly loose materials on the surface of the formation, such as soil, clay, weathered rock, sand and gravel, etc. | It is suitable for drilling geothermal wells, water wells, small and medium-sized grouting holes in buildings, micro piles, etc. | Ensures even drilling force and excellent borehole straightness, making it suitable for construction with diameters up to φ800mm. |

More Parameters

| Connection Type | Outer Dia.(mm) | Slide Blocks No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 168 | 2 | 185 | DHD350/SD5/QL50/M50 | 30 |

| Left-handed | 178 | 2 | 195 | DHD350/SD5/QL50/M50 | 35 |

| Left-handed | 183 | 2 | 200 | DHD350/SD5/QL50/M50 | 39 |

| Left-handed | 194 | 2 | 209 | DHD360/SD6/QL60/M60 | 48 |

| Left-handed | 219 | 3 | 234 | DHD360/SD6/QL60/M60 | 61 |

| Left-handed | 245 | 3 | 260 | DHD380/SD8/QL80 | 88 |

| Left-handed | 273 | 3 | 305 | DHD380/SD8/QL80 | 96.5 |

| Left-handed | 325 | 3 | 346 | DHD380/SD8/QL80 | 115 |

| Left-handed | 355 | 3 | 376 | DHD112/NUMA120 | 214 |

| Left-handed | 406 | 4 | 432 | DHD112/NUMA125/QL120 | 254 |

| Left-handed | 460 | 4 | 485 | TH14/NUMA125 | 415 |

| Left-handed | 480 | 4 | 505 | TH14 | 455 |

| Left-handed | 508 | 4 | 534 | NUMA125/TH18K | 630 |

| Left-handed | 560 | 4 | 590 | NUMA125/TH18K | 730 |

| Outer Dia.(mm) | Pilot Bit Dia.(mm) | Reamed Dia.(mm) | Type of Hammer | Connection Type | Weight (kg) |

| 76 | 57 | 88 | R32 | Sleeve Weld | 3.2 |

| 89 | 70 | 102 | T38/R38 | Sleeve Weld | 5.8 |

| 114 | 94 | 128 | T38/R38 | Sleeve Weld | 7.5 |

| 114 | 92 | 128 | DHD3.5 | Sleeve Weld | 10 |

| 127 | 105 | 142 | T45 | Sleeve Weld | 10 |

| 127 | 105 | 142 | DHD3.5 | Sleeve Weld | 16 |

| 140 | 116.5 | 161 | T46/T51 | Sleeve Weld | 15 |

| 140 | 116.5 | 161 | DHD340/SD4/QL40 | Sleeve Weld | 21 |

| 146 | 123 | 165 | DHD340/SD4/QL40 | Sleeve Weld | 22 |

| 168 | 141 | 188 | DHD350/SD5/QL50/M50 | Sleeve Weld | 27 |

| 178 | 155 | 198 | DHD350/SD5/QL50/M50 | Sleeve Weld | 32.5 |

| 194 | 166 | 214 | DHD360/SD6/QL60/M60 | Sleeve Weld | 42.5 |

| 219 | 191 | 243 | DHD360/SD6/QL60/M60 | Sleeve Weld | 58 |

| 76 | 58 | 86 | R32 | Butt Weld | 3.2 |

| 89 | 70 | 95 | T38/R38 | Butt Weld | 5.8 |

| 114 | 92 | 122 | T38/R38 | Butt Weld | 7.5 |

| 114 | 92 | 122 | DHD3.5 | Butt Weld | 10 |

| 127 | 105 | 138 | T45 | Butt Weld | 10 |

| 127 | 105 | 138 | DHD3.5 | Butt Weld | 16 |

| 140 | 118 | 152 | T45/T51 | Butt Weld | 15 |

| 140 | 118 | 152 | DHD340/SD4/QL40 | Butt Weld | 21 |

| 146 | 124 | 158 | DHD340/SD4/QL40 | Butt Weld | 22 |

| 168 | 146 | 184 | DHD350/SD5/QL50/M50 | Butt Weld | 27 |

| 108 | 92 | 118 | DHD3.5 | Left-handed | 10.1 |

| 114 | 99 | 126 | DHD3.5 | Left-handed | 13.8 |

| 127 | 106 | 138 | DHD3.5 | Left-handed | 18 |

| 140 | 120 | 151 | DHD340/SD4/QL40 | Left-handed | 21 |

| 146 | 124 | 156 | DHD340/SD4/QL40 | Left-handed | 23.5 |

| 168 | 146 | 184 | DHD350/SD5/QL50/M50 | Left-handed | 27.5 |

| 178 | 156 | 192 | DHD350/SD5/QL50/M50 | Left-handed | 42 |

| 194 | 172 | 206 | DHD360/SD6/QL60/M60 | Left-handed | 57.5 |

| 219 | 196 | 234 | DHD360/SD6/QL60/M60 | Left-handed | 75 |

| 245 | 218 | 260 | DHD380/SD80/QL80 | Left-handed | 105 |

| 273 | 245 | 298 | DHD380/SD80/QL80 | Left-handed | 122 |

| 325 | 295 | 350 | DHD380/NUMA100 | Left-handed | 135 |

| 406 | 378 | 438 | DHD112/QL120/SD12 | Left-handed | 420 |

| 508 | 478 | 538 | SD18/NUMA180/TH18K | Left-handed | 522 |

| Connection Type | Outer Dia.(mm) | Wall Thickness(mm) | Wings No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 114 | 6.5 | 2 | 125 | DHD3.5 | 15 |

| Left-handed | 146 | 10 | 2 | 157 | DHD340/SD4/QL40 | 20.3 |

| Left-handed | 168 | 10 | 2 | 180 | DHD350/SD5/QL50 | 33.4 |

| Left-handed | 178 | 10 | 2 | 195 | DHD350/SD5/QL50 | 38.8 |

| Left-handed | 194 | 10 | 2 | 206 | DHD350/SD5/QL50 | 46.4 |

| Left-handed | 219 | 10 | 2 | 237 | DHD360/SD6/QL60/M60 | 72 |

| Left-handed | 240 | 10 | 2 | 265 | DHD380/SD8/QL80 | 102 |

| Left-handed | 273 | 10 | 2 | 308 | DHD380/SD8/QL80 | 125 |

| Left-handed | 323 | 10 | 3 | 360 | DHD380/NUMA100 | 138 |

| Connection Type | Outer Dia.(mm) | Slide Blocks No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 168 | 2 | 185 | DHD350/SD5/QL50/M50 | 30 |

| Left-handed | 178 | 2 | 195 | DHD350/SD5/QL50/M50 | 35 |

| Left-handed | 183 | 2 | 200 | DHD350/SD5/QL50/M50 | 39 |

| Left-handed | 194 | 2 | 209 | DHD360/SD6/QL60/M60 | 48 |

| Left-handed | 219 | 3 | 234 | DHD360/SD6/QL60/M60 | 61 |

| Left-handed | 245 | 3 | 260 | DHD380/SD8/QL80 | 88 |

| Left-handed | 273 | 3 | 305 | DHD380/SD8/QL80 | 96.5 |

| Left-handed | 325 | 3 | 346 | DHD380/SD8/QL80 | 115 |

| Left-handed | 355 | 3 | 376 | DHD112/NUMA120 | 214 |

| Left-handed | 406 | 4 | 432 | DHD112/NUMA125/QL120 | 254 |

| Left-handed | 460 | 4 | 485 | TH14/NUMA125 | 415 |

| Left-handed | 480 | 4 | 505 | TH14 | 455 |

| Left-handed | 508 | 4 | 534 | NUMA125/TH18K | 630 |

| Left-handed | 560 | 4 | 590 | NUMA125/TH18K | 730 |

Casing shoe

| Outer Dia.(mm) | Wall Thickness(mm) | Inside Diameter(mm) | Connection Type |

| 76 | 8 | 47 | Sleeve Weld |

| 89 | 8 | 51 | Sleeve Weld |

| 108 | 7 | 86 | Sleeve Weld |

| 114 | 6.5 | 91 | Sleeve Weld |

| 127 | 9.5 | 100 | Sleeve Weld |

| 146 | 10 | 117 | Sleeve Weld |

| 168 | 10 | 138 | Sleeve Weld |

| 178 | 10 | 148 | Sleeve Weld |

| 183 | 10 | 153 | Sleeve Weld |

| 194 | 10 | 162 | Sleeve Weld |

| 219 | 10 | 187 | Sleeve Weld |

Casing

| Outer Dia.(mm) | Wall Thickness(mm) | Length(mm) | Thread Direction | Connection Type |

| 76 | 8 | 3000 | Right-handed | MF thread or joint connection |

| 89 | 8 | 3000 | Right-handed | MF thread or joint connection |

| 108 | 7 | 1500 | Left-handed | Joint connection |

| 114 | 6.5 | 1500 | Left-handed | MF thread or joint connection |

| 127 | 9.5 | 1500 | Left-handed | MF thread or joint connection |

| 146 | 10 | 1500 | Left-handed | MF thread or joint connection |

| 168 | 10 | 1500 | Left-handed | MF thread or joint connection |

| 178 | 10 | 1500 | Left-handed | MF thread or joint connection |

| 183 | 10 | 1500 | Left-handed | MF thread or joint connection |

| 194 | 10 | 1500 | Left-handed | MF thread or joint connection |

| 219 | 10 | 1500 | Left-handed | MF thread or joint connection |

Can't find the parameters you want? Please get in touch with us!

Download BrochureAdvantages

High-Efficiency Drilling

Kelleg’s casing systems incorporate advanced drilling technology and design, enabling efficient performance even in challenging formations, such as hard rock, loose ground, fractured zones, and gravel layers. With a compact structure and user-friendly operation, our tools significantly enhance construction efficiency, shorten project timelines, and reduce costs.

Stable and Reliable

Designed for intensity and durability, Kelleg’s casing systems are manufactured using high-quality materials and undergo rigorous testing to ensure consistent performance in harsh working conditions.

Versatile Adaptability

Kelleg’s casing systems offer broad adaptability to accommodate various geological conditions and project requirements. Our product range includes eccentric and concentric casing drilling systems with customizable solutions to meet specific customer needs.

Superior Borehole Stability

With a unique structural design, Kelleg’s casing systems provide borehole support during drilling, preventing collapse and sand inflow issues. This not only improves the safety of the construction but also ensures the quality and stability of the drilled holes.

Construction Process

of Casing System