Rock drill bits are specialized tools designed for drilling operations that break and penetrate hard rock layers. They are commonly utilized in industries such as mining, construction, oil and gas exploration, and quarrying. These bits work in conjunction with drill rods and a rock drill machine to effectively rock drilling. Its design and material characteristics ensure it can withstand extreme conditions, providing reliable and efficient performance in challenging environments.

Types of Rock Drill Bits

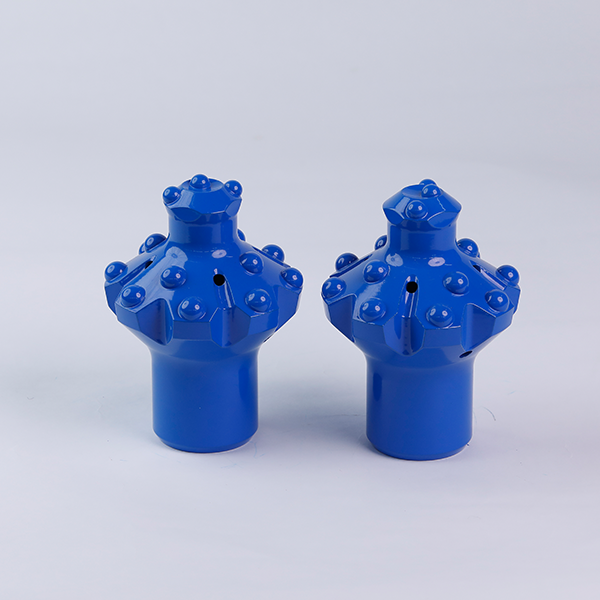

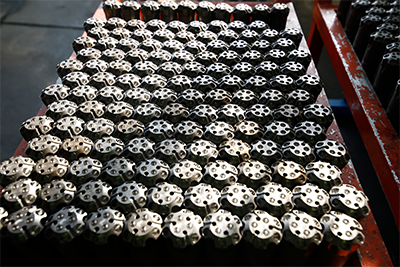

We offer a variety of rock drill bits, including Cross Bits and Button Bits. Among them, Button Bits include Threaded Button Bits, Retrac Button Bits, and Reaming Button Bits.

| Type | Brief Introduction | Application | Diameter |

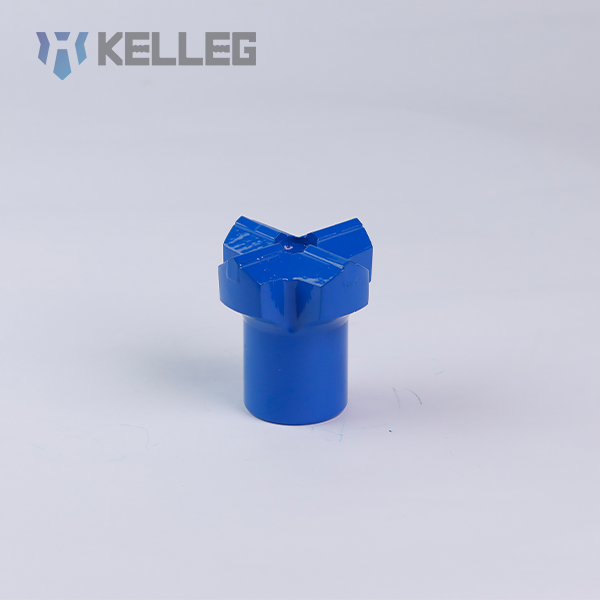

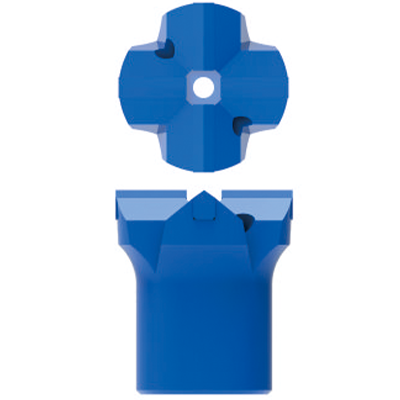

Cross Bit |

The design usually incorporates multiple cross blades arranged in a cross shape, enhancing its effectiveness in breaking rocks during drilling. | It is primarily utilized for drilling through fissured rocks and abrasive formations like limestone, granite, and marble. It is particularly suitable for high-impact rock drilling machines. | 34mm-65mm |

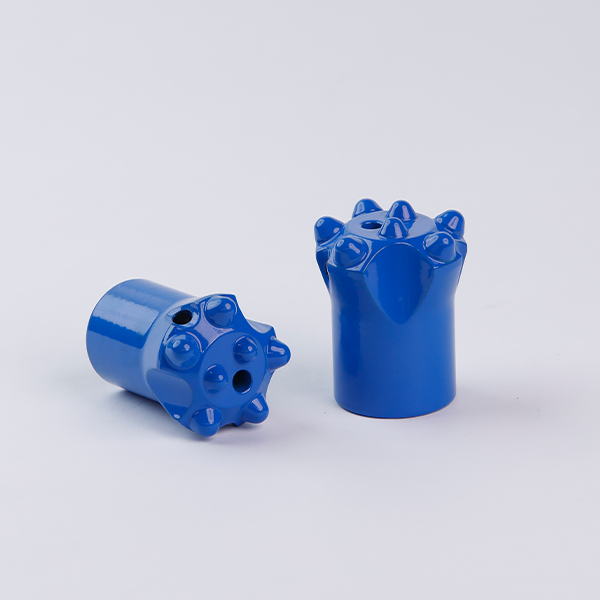

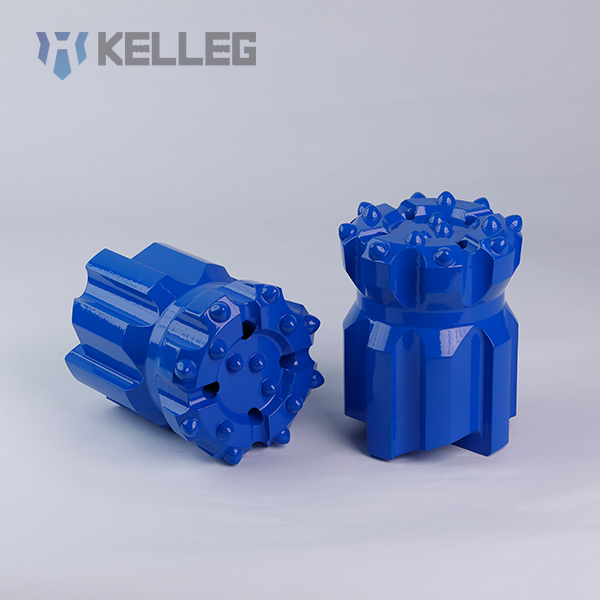

Button Bit |

This drill bit features carbide button inserts strategically arranged on its body. This design allows for multi-point rock breaking, which enhances efficiency and eliminates blind spots commonly encountered in rock-breaking operations. Additionally, it prevents the re-breaking of rock debris. | Various diameters of threaded button bits are utilized with drill jumbos to handle different types of hard and brittle rock formations. | 38mm-150mm |

| Button Bit Type | Brief Introduction | Application | Diameter |

Threaded Button Bit |

The rock drill bit connects to the threaded drill rod, transferring the impact and rotary torque from the rock drill to break rocks. | This rock drill bit is suitable for drilling under general geological conditions. It features a straightforward design with evenly distributed carbide buttons, making it suitable for various rock hardness levels. | 48mm-152mm |

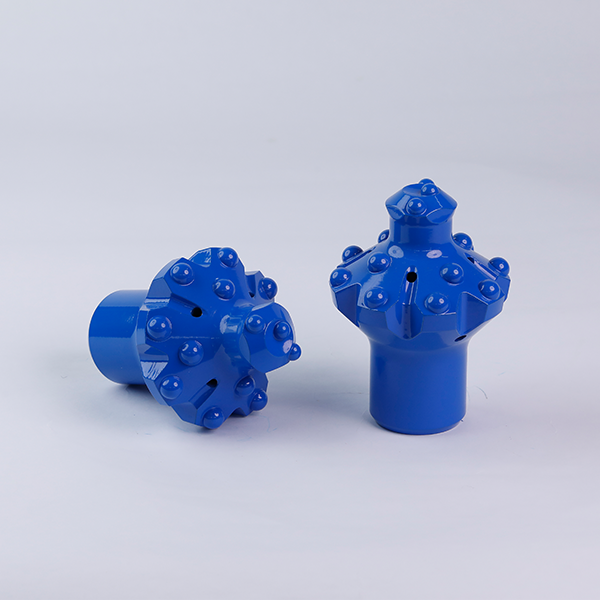

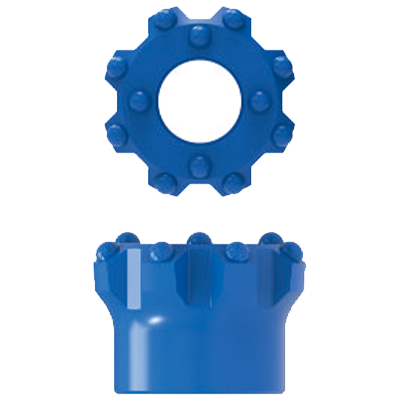

Retrac Button Bit |

Designed with a unique structure and manufacturing process, this bit improves drilling efficiency. It typically features a hollow design that helps expel rock cuttings from the drilling zone, reducing the risk of drill bit jamming. | It is mainly used in loose, fragmented rock formations and helps with the retrieval of rock drilling tools, reducing the risk of jamming and improving straightness in drilled holes. Commonly used in mining and tunnel excavation projects. | 45mm-152mm |

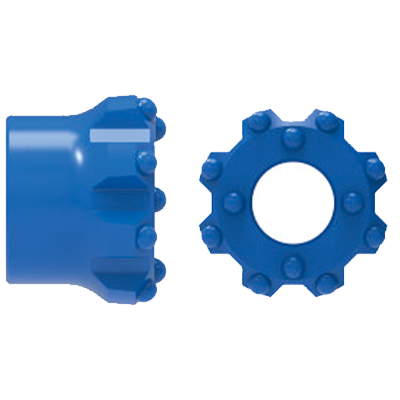

Reaming Button Bit |

This tool drills a pilot hole to a specific depth, then reams the hole to a larger diameter. | It is primarily used for reaming the central hole in deep hole drilling. | 64mm-152mm |

More Parameters

Rock drill bits are divided into R thread and T thread, models include R25, R28, R32, R38, T38, T45, T51, etc. Different product types and models can be selected according to different engineering requirements.

11° Tapered Bit

| Drill Bit | Bit Dia. | No.×Button Dia. | Flushing Hole | Skirt Type | Weight (kg) |

||||

| mm | inch | Front | Gauge | Angle | Front | Side | |||

| Button Bit  |

32 | 1 1/4 | 1×8 | 3×8 | 35° | 1 | 2 | Short Skirt | 0.24 |

| 32 | 1 1/4 | 2×7 | 5×7 | 40° | 1 | 1 | 0.24 | ||

| 33 | 1 19/64 | 2×7 | 4×7 | 40° | 1 | 1 | 0.25 | ||

| 34 | 1 11/32 | 2×7 | 4×7 | 40° | 1 | 1 | 0.29 | ||

| 35 | 1 3/8 | 2×7 | 5×7 | 35° | 1 | 1 | 0.33 | ||

| 35 | 1 3/8 | 2×7 | 5×8 | 35° | 1 | 1 | 0.33 | ||

| 36 | 1 27/64 | 1×8 | 3×9 | 40° | 1 | 1 | 0.36 | ||

| 36 | 1 27/64 | 2×7 | 4×7 | 40° | 1 | 1 | 0.36 | ||

| 36 | 1 27/64 | 2×7 | 5×8 | 35° | 1 | 1 | 0.36 | ||

| 38 | 1 1/2 | 1×9 | 3×9 | 40° | 1 | 1 | 0.39 | ||

| 38 | 1 1/2 | 2×8 | 3×9 | 40° | 1 | 1 | 0.39 | ||

| 38 | 1 1/2 | 2×7 | 5×8 | 35° | 1 | 1 | 0.39 | ||

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.39 | ||

| 40 | 1 37/64 | 1×9 | 3×9 | 40° | 1 | 1 | 0.40 | ||

| 40 | 1 37/64 | 2×8 | 3×9 | 40° | 1 | 1 | 0.40 | ||

| 40 | 1 37/64 | 2×9 | 3×9 | 40° | 1 | 2 | 0.40 | ||

| 40 | 1 37/64 | 2×7 | 5×9 | 35° | 1 | 1 | 0.40 | ||

| 40 | 1 37/64 | 2×8 | 5×9 | 35° | 1 | 1 | 0.40 | ||

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | ||

| 32 | 1 1/4 | 2×7 | 5×7 | 35° | 1 | 1 | Long Skirt | 0.30 | |

| 33 | 1 19/64 | 2×7 | 5×7 | 35° | 1 | 1 | 0.31 | ||

| 33 | 1 19/64 | 2×7 | 6×7 | 40° | 1 | 1 | 0.31 | ||

| 35 | 1 3/8 | 2×7 | 6×7 | 40° | 1 | 1 | 0.35 | ||

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | ||

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.42 | ||

| 35 | 1 3/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.38 | ||

| 36 | 1 27/64 | 2×7 | 5×9 | 35° | 1 | 1 | 0.39 | ||

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | ||

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.42 | ||

Cross-type Bit |

29 | 1 9/64 | 12×8 | - | 1 | 2 | - | 0.25 | |

| 30 | 1 3/16 | 12×8 | - | 1 | 2 | 0.26 | |||

| 32 | 1 1/4 | 12×8 | - | 1 | 2 | 0.30 | |||

| 33 | 1 19/64 | 12×8 | - | 1 | 2 | 0.32 | |||

| 35 | 1 3/8 | 12×8 | - | 1 | 2 | 0.36 | |||

| 36 | 1 27/64 | 12×8 | - | 1 | 2 | 0.39 | |||

| 38 | 1 1/2 | 12×8 | - | 1 | 2 | 0.43 | |||

| 41 | 1 5/8 | 14×8 | - | 1 | 2 | 0.49 | |||

R32

| Drill Bit | Bit Dia. | No.×Button Dia. | Flushing Hole | Weight (kg) | ||||

| mm | inch | Front | Gauge | Angle | Front | Side | ||

Button Bit |

Spherical Buttons | |||||||

| 41 | 1 5/8 | 2×9 | 4×9 | 35° | 1 | 1 | 0.6 | |

| 41 | 1 5/8 | 2×8 | 5×9 | 35° | 1 | 1 | 0.7 | |

| 43 | 1 11/16 | 2×9 | 5×9 | 35° | 1 | 2 | 0.7 | |

| 43 | 1 11/16 | 2×9 | 5×10 | 35° | 1 | 1 | 0.7 | |

| 43 | 1 11/16 | 2×9 | 6×9 | 40° | 2 | - | 0.7 | |

| 45 | 1 3/4 | 2×9 | 5×11 | 30° | 1 | 1 | 0.8 | |

| 45 | 1 3/4 | 2×9 | 6×10 | 35° | 2 | - | 0.8 | |

| 45 | 1 3/4 | 3×8 | 6×10 | 30° | 3 | - | 0.8 | |

| 48 | 1 7/8 | 2×9 | 5×11 | 35° | 1 | 1 | 0.9 | |

| 48 | 1 7/8 | 2×9 | 6×10 | 40° | 2 | - | 0.9 | |

| 48 | 1 7/8 | 3×8 | 6×10 | 40° | 3 | - | 0.9 | |

| 48 | 1 7/8 | 3×9 | 6×10 | 30° | 3 | - | 0.9 | |

| 51 | 2 | 2×10 | 5×11 | 35° | 1 | 1 | 1.0 | |

| 51 | 2 | 2×10 | 6×10 | 40° | 2 | - | 1.0 | |

| 51 | 2 | 3×9 | 6×10 | 35° | 3 | - | 1.0 | |

| 57 | 2 1/4 | 3×9 | 6×11 | 35° | 3 | - | 1.3 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | - | 1.6 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 1.6 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | - | 2.6 | |

| Parabolic Buttons | ||||||||

| 41 | 1 5/8 | 2×8 | 5×9 | 40° | 1 | 1 | 0.7 | |

| 43 | 1 11/16 | 2×9 | 5×9 | 40° | 1 | 2 | 0.7 | |

| 43 | 1 11/16 | 2×9 | 6×9 | 40° | 2 | - | 0.7 | |

| 43 | 1 11/16 | 3×8 | 6×8 | 40° | 3 | 1 | 0.7 | |

| 45 | 1 3/4 | 2×9 | 5×11 | 30° | 1 | 2 | 0.8 | |

| 45 | 1 3/4 | 2×9 | 6×9 | 40° | 2 | 2 | 0.8 | |

| 45 | 1 3/4 | 3×8 | 6×9 | 40° | 3 | 1 | 0.8 | |

| 48 | 1 7/8 | 2×9 | 5×11 | 35° | 1 | 1 | 0.9 | |

| 48 | 1 7/8 | 2×9 | 6×10 | 40° | 2 | - | 0.9 | |

| 48 | 1 7/8 | 3×8 | 6×10 | 40° | 3 | - | 0.9 | |

| 51 | 2 | 2×10 | 6×10 | 40° | 2 | - | 1.0 | |

| 51 | 2 | 3×9 | 6×10 | 40° | 3 | 1 | 1.0 | |

| 54 | 2 1/8 | 3×9 | 6×10 | 40° | 3 | 1 | 1.0 | |

| 57 | 2 1/4 | 3×9 | 6×11 | 35° | 3 | - | 1.3 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 1.6 | |

| Drill Bit | Bit Dia. | No.×Button Dia. | Flushing Hole | Weight (kg) | ||||

| mm | inch | Front | Gauge | Angle | Front | Side | ||

Retrac Button Bit |

Spherical Buttons | |||||||

| 45 | 1 3/4 | 3×8 | 6×9 | 40° | 3 | - | 1.1 | |

| 48 | 1 7/8 | 3×9 | 6×10 | 30° | 3 | - | 1.2 | |

| 51 | 2 | 3×9 | 6×10 | 30° | 3 | - | 1.4 | |

| 64 | 2 1/2 | 3×10, 1×10 | 6×11 | 35° | 3 | - | 2.2 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 2.2 | |

| 76 | 3 | 4×11,1×11 | 8×11 | 35° | 4 | 1 | 3.5 | |

| Parabolic Buttons | ||||||||

| 45 | 1 3/4 | 3×8 | 6×9 | 40° | 3 | - | 1.1 | |

| 48 | 1 7/8 | 3×9 | 6×10 | 30° | 3 | - | 1.2 | |

| 51 | 2 | 3×9 | 6×10 | 30° | 3 | - | 1.4 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | - | 2.2 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 2.2 | |

| 76 | 3 | 4×11,1×11 | 8×11 | 35° | 4 | 1 | 3.5 | |

Dome Bit for Reaming |

Spherical Buttons | |||||||

| 76 | 3 | 1×13 | 9×13 | 35° | 3 | 1 | 2.0 | |

| 89 | 3 1/2 | 1×13 | 14×13 | 35° | 2 | 2 | 2.6 | |

| 102 | 4 | 1 ×13 | 16×13 | 35° | 2 | 2 | 3.2 | |

| 127 | 5 | 1×13 | 18×13 | 35° | 3 | 1 | 4.8 | |

| Parabolic Buttons | ||||||||

| 76 | 3 | 1×13 | 9×13 | 35° | 3 | 1 | 2.0 | |

| 89 | 3 1/2 | 1×13 | 14×13 | 35° | 2 | 2 | 2.6 | |

| 102 | 4 | 1×13 | 16×13 | 35° | 2 | 2 | 3.2 | |

| 127 | 5 | 1×13 | 18×13 | 35° | 3 | 1 | 4.8 | |

Reaming Bit 6° |

64 | 2 1/2 | 2×10 | 8×9 | 35° | - | - | 0.8 |

| 64 | 2 1/2 | 4×8 | 8×9 | 25° | - | - | 0.8 | |

| 76 | 3 | 2×11 | 8×11 | 35° | - | - | 1.2 | |

| 76 | 3 | 4×10 | 8×10 | 30° | - | - | 1.2 | |

| 89 | 3 1/2 | 4×11 | 8×11 | 35° | - | - | 1.7 | |

| 89 | 3 1/2 | 4×10 | 8×10 | 30° | - | - | 1.7 | |

Pilot Adapter 6° |

26 | 1 1/32 | 12×8 | - | - | - | 1.5 | |

Reaming Bit 12° |

89 | 3 1/2 | 4×10 | 8×12 | 35° | - | - | 1.8 |

| 102 | 4 | 4×12 | 8×12 | 35° | - | - | 2.1 | |

| 127 | 5 | 4×12 | 8×12 | 35° | - | - | 4.0 | |

| 127 | 5 | 4×13 | 8×13 | 35° | - | - | 4.0 | |

Pilot Adapter 12° |

40 | 1 37/64 | 15×10 | - | - | - | 2.2 | |

Cross-type Bit |

41 | 1 5/8 | 16×10 | - | 1 | 4 | 0.7 | |

| 43 | 1 11/16 | 16×10 | - | 1 | 2 | 0.8 | ||

| 45 | 1 3/4 | 16×10 | - | 1 | 4 | 0.9 | ||

| 48 | 1 7/8 | 16×10 | - | 1 | 4 | 0.9 | ||

| 51 | 2 | 16×10 | - | 1 | 4 | 1.2 | ||

| 57 | 2 1/4 | 16×10 | - | 1 | 4 | 1.3 | ||

| 64 | 2 1/2 | 18×13 | - | 1 | 4 | 1.5 | ||

T38

| Drill Bit | Bit Dia. | No.×Button Dia. | Flushing Hole | Weight (kg) |

||||

| mm | inch | Front | Gauge | Angle | Front | Side | ||

Button Bit |

Spherical Buttons | |||||||

| 64 | 2 1/2 | 3×11 | 6×12 | 35° | 3 | - | 1.8 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 1.6 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | - | 1.7 | |

| 70 | 2 3/4 | 4×11 | 8×11 | 40° | 2 | - | 1.9 | |

| 70 | 2 3/4 | 4×10,1×10 | 8×11 | 30° | 4 | - | 1.9 | |

| 70 | 2 3/4 | 3×10,1×10 | 6×12 | 35° | 3 | - | 1.8 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | - | 2.4 | |

| 76 | 3 | 5×11 | 8×13 | 35° | 2 | 1 | 2.4 | |

| 76 | 3 | 3×11,1×11 | 6×12 | 35° | 3 | 1 | 2.6 | |

| 76 | 3 | 4×11,1×11 | 8×12 | 35° | 4 | - | 2.6 | |

| 76 | 3 | 4×11,1 ×11 | 8×11 | 40° | 4 | - | 2.6 | |

| 89 | 3 1/2 | 4×13 | 8×13 | 40° | 2 | - | 3.3 | |

| 89 | 3 1/2 | 5×13 | 8×13 | 35° | 2 | - | 3.3 | |

| 89 | 3 1/2 | 6×11 | 8×12 | 35° | 2 | - | 3.3 | |

| 89 | 3 1/2 | 3×11,2×11 | 6×13 | 35° | 3 | 1 | 3.3 | |

| 89 | 3 1/2 | 4×11,1×11 | 8×13 | 35° | 4 | - | 3.3 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | - | 3.3 | |

| Parabolic Buttons | ||||||||

| 64 | 2 1/2 | 3×11 | 6×12 | 35° | 3 | - | 1.8 | |

| 64 | 2 1/2 | 4×10 | 8×10 | 40° | 2 | - | 1.6 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | - | 1.7 | |

| 70 | 2 3/4 | 4×11 | 8×11 | 40° | 2 | - | 1.9 | |

| 70 | 2 3/4 | 3×10,1 ×10 | 6×12 | 35° | 3 | - | 1.8 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | - | 2.4 | |

| 76 | 3 | 5×11 | 8×13 | 35° | 2 | 1 | 2.4 | |

| 76 | 3 | 3×11,1×11 | 6×13 | 35° | 3 | 1 | 2.6 | |

| 76 | 3 | 4×11,1×11 | 8×12 | 35° | 4 | - | 2.6 | |

| 76 | 3 | 4×11,1 ×11 | 8×11 | 40° | 4 | - | 2.6 | |

| 89 | 3 1/2 | 5×13 | 8×13 | 35° | 2 | - | 3.3 | |

| 89 | 3 1/2 | 6×11 | 8×12 | 35° | 2 | - | 3.3 | |

| 89 | 3 1/2 | 3×11,2×11 | 6×13 | 35° | 3 | 1 | 3.3 | |

| 89 | 3 1/2 | 4×11,1×11 | 8×13 | 35° | 4 | - | 3.3 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | - | 3.3 | |

Retrac Button Bit |

Spherical Buttons | |||||||

| 64 | 2 1/2 | 4×10 | 8×10 | 30° | 2 | — | 2.2 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | — | 2.2 | |

| 70 | 2 3/4 | 4×11 | 8×11 | 40° | 2 | — | 2.4 | |

| 70 | 2 3/4 | 3×10,1×10 | 6×13 | 35° | 3 | — | 2.4 | |

| 70 | 2 3/4 | 4×10,1×10 | 8×11 | 35° | 4 | — | 2.4 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | — | 3.3 | |

| 76 | 3 | 4×11,1×11 | 8×11 | 35° | 4 | — | 3.3 | |

| 76 | 3 | 4×11, 1×11 | 8×12 | 35° | 4 | — | 3.3 | |

| 89 | 3 1/2 | 4×13 | 8×13 | 40° | 2 | — | 4.8 | |

| 89 | 3 1/2 | 5×13 | 8×13 | 35° | 2 | — | 4.8 | |

| 89 | 3 1/2 | 6×11 | 8×12 | 35° | 2 | — | 4.8 | |

| 89 | 3 1/2 | 4×11, 1×11 | 8×13 | 35° | 4 | — | 4.8 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | — | 4.8 | |

| Parabolic Buttons | ||||||||

| 64 | 2 1/2 | 4×10 | 8×10 | 30° | 2 | - | 2.2 | |

| 64 | 2 1/2 | 3×10,1×10 | 6×11 | 35° | 3 | - | 2.2 | |

| 70 | 2 3/4 | 4×11 | 8×11 | 40° | 2 | - | 2.4 | |

| 70 | 2 3/4 | 3×10,1 ×10 | 6×13 | 35° | 3 | - | 2.4 | |

| 70 | 2 3/4 | 4×10,1×10 | 8×11 | 35° | 4 | - | 2.4 | |

| 76 | 3 | 4×11 | 8×11 | 40° | 2 | - | 3.3 | |

| 76 | 3 | 4×11, 1 ×11 | 8×11 | 35° | 4 | - | 3.3 | |

| 76 | 3 | 4×11, 1 ×11 | 8×12 | 35° | 4 | - | 3.3 | |

| 89 | 3 1/2 | 4×13 | 8×13 | 40° | 2 | - | 4.8 | |

| 89 | 3 1/2 | 5×13 | 8×13 | 35° | 2 | - | 4.8 | |

| 89 | 3 1/2 | 6×11 | 8×12 | 35° | 2 | - | 4.8 | |

| 89 | 3 1/2 | 4×11,1 ×11 | 8×13 | 35° | 4 | - | 4.8 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | - | 4.8 | |

| X-type Bit | 64 | 2 1/2 | 25×13 | - | 1 | 2 | 1.9 | |

| 76 | 3 | 25×13 | - | 1 | 2 | 2.5 | ||

| 89 | 3 1/2 | 25×13 | - | 1 | 2 | 2.8 | ||

Dome Bit for Reaming |

Spherical Buttons | |||||||

| 102 | 4 | 1×13 | 16×13 | 35° | 2 | 2 | 3.8 | |

| 127 | 5 | 1×13 | 18×13 | 35° | 1 | 3 | 5.2 | |

| Parabolic Buttons | ||||||||

| 102 | 4 | 1×13 | 16×13 | 35° | 2 | 2 | 3.8 | |

| 127 | 5 | 1×13 | 18×13 | 35° | 1 | 3 | 5.2 | |

ST58

| Drill Bit | Bit Dia. | No.×Button Dia. | Flushing Hole | Weight (kg) |

||||

| mm | inch | Front | Gauge | Angle | Front | Side | ||

Button Bit |

Spherical Buttons | |||||||

| 89 | 3 1/2 | 6×12 | 8×12 | 35° | 2 | 1 | 4.1 | |

| 89 | 3 1/2 | 6×13 | 8×13 | 35° | 2 | 1 | 4.1 | |

| 89 | 3 1/2 | 4×13,1 ×13 | 8×13 | 35° | 4 | — | 4.1 | |

| 89 | 3 1/2 | 4×12,2×12 | 8×12 | 35° | 4 | — | 4.1 | |

| 95 | 3 3/4 | 4×13,1×13 | 8×14 | 35° | 4 | — | 4.6 | |

| 102 | 4 | 6×14 | 8×14 | 35° | 2 | — | 6.0 | |

| 102 | 4 | 6×13 | 8×16 | 35° | 2 | 1 | 6.0 | |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | — | 7.0 | |

| Parabolic Buttons | ||||||||

| 89 | 3 1/2 | 6×12 | 8×12 | 35° | 2 | 1 | 4.1 | |

| 89 | 3 1/2 | 6×13 | 8×13 | 35° | 2 | 1 | 4.1 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | — | 4.1 | |

| 89 | 3 1/2 | 4×12,2×12 | 8×12 | 35° | 4 | — | 4.1 | |

| 95 | 3 3/4 | 4×13,1 ×13 | 8×14 | 35° | 4 | — | 4.6 | |

| 102 | 4 | 6×14 | 8×14 | 35° | 2 | — | 6.0 | |

| 102 | 4 | 6×13 | 8×16 | 35° | 2 | 1 | 6.0 | |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | — | 7.0 | |

Retrac Button Bit |

Spherical Buttons | |||||||

| 89 | 3 1/2 | 6×12 | 8×14 | 35° | 2 | 1 | 5.1 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | — | 5.1 | |

| 102 | 4 | 7×12 | 8×14 | 35° | 2 | 1 | 6.5 | |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | — | 8.5 | |

| Parabolic Buttons | ||||||||

| 89 | 3 1/2 | 6×12 | 8×14 | 35° | 2 | 1 | 5.1 | |

| 89 | 3 1/2 | 4×13,1×13 | 8×13 | 35° | 4 | — | 5.1 | |

| 102 | 4 | 7×12 | 8×14 | 35° | 2 | 1 | 6.5 | |

| 115 | 4 1/2 | 6×14 | 8×16 | 35° | 2 | — | 8.5 | |

Dome Bit for Reaming |

Spherical Buttons | |||||||

| 152 | 6 | 6×16 | 9×16 | 35° | 3 | — | 13.0 | |

| 152 | 6 | 2×14 | 18×14 | 35° | 3 | 3 | 10.4 | |

| Parabolic Buttons | ||||||||

| 152 | 6 | 6×16 | 9×16 | 35° | 3 | — | 13.0 | |

| 152 | 6 | 2×14 | 18×14 | 35° | 3 | 3 | 10.4 | |

Can't find the parameters you want? Please get in touch with us!

Download BrochureAdvantages

Our rock drill bits are meticulously designed to meet the rigorous requirements of mining, construction, oil and gas exploration, and quarrying industries. These tools are designed to excel in the most challenging drilling environments, ensuring maximum performance, durability, and precision.

High-Quality Materials

Made from 45CrNiMo1V high-performance alloy steel, which provides high strength, good toughness, excellent wear resistance, and corrosion resistance. It ensures that the rock drill bit offers stable performance and long service life, even in harsh rock drilling conditions.

Ingenious Design

· The structural design ensures effective torque transmission and impact load resistance.

· The cutting edges are optimized to enhance drilling efficiency.

· Strong adaptability, suitable for various types of rock drill machines.

Advanced Manufacturing Process

· The alloy is bonded to the bit body using the best heat-sintering process, ensuring a strong bond between the alloy and the base material.

· The bit body undergoes heat treatment to improve the mechanical properties and microstructure of the material.

· The processing technology is mature, using advanced CNC equipment and inspection techniques to ensure product precision and consistency.

Strict Quality Control

· Raw materials are strictly tested to meet design specifications.

· Strict control and testing during the production process to ensure the consistency and stability of product quality.

· Finished products undergo stringent inspections for appearance quality, dimensional accuracy, and mechanical properties, ensuring they meet design requirements and customer needs.

Selection of Rock Drill Bit

Selection of Rock Drill Bit Face

| Bit face | Application | Rock Consolidation Condition | Drilling Speed |

flat face |

For use in all rock conditions, especially for harsh or abrasive conditions such as granite, basalt, and hard limestone | much | slow |

drop center |

Drill straighter holes in less consolidated rock | middle | middle |

semi-dome |

For soft rock, such as low-silica shale and limestone | less | fast |

Selection of Carbide Button

| Carbide Button | Picture | Advantages | Application |

| Conical Button |  |

High drilling efficiency | medium-hard rock such as limestone, gravel, marble, pyrite, etc. from f8 to f14. |

| Parabolic Button |  |

The button feeding speed is fast, which can not only ensure a certain rock drilling efficiency but also have a better service life. | medium hard rock moderately corrosive rock formations |

| Ogive Button |  |

Fast button feed speed and excellent rock drilling efficiency | soft rock such as shale, clay rock, sandstone, and rock salt below f8 |