Rock drilling refers to the construction process of drilling holes in rocks, typically accomplished using specialized equipment such as a rock drill. It is widely applied in various fields, including mining, tunnel excavation, building foundation construction, and road building. In rock-drilling projects, to achieve an ideal drilling outcome, strict control of the drilling direction is essential. Any deviation in the drilling direction can affect the drilling results and even impact the overall quality and progress of the project. So, apart from the drilling direction, what other factors can influence the rock-drilling effect?

Construction Environment

The construction environment mainly includes two aspects: rock hardness and rock mass geological conditions.

Rock Hardness

Rock hardness has a significant impact on rock drilling. On the one hand, rock hardness is directly related to the efficiency of rock drilling. Higher-hardness rocks require greater impact and torque to break the rock formation, which significantly reduces the rock-drilling speed. In contrast, softer rocks have a relatively loose internal structure and require less energy to break, so the rock-drilling speed is relatively faster.

On the other hand, rocks of different hardness have different performance requirements for rock-drilling equipment. High-hardness rocks need greater impact force and torque to be broken, which places higher demands on the power and durability of rock drills. If the equipment is not properly selected, not only will the efficiency be low when drilling in hard rocks, but also the wear and tear of the equipment will be accelerated, increasing maintenance costs and time. In soft rocks, although the rock-drilling difficulty is relatively low, problems such as hole wall collapse may occur. It is also necessary to reasonably select construction techniques and equipment parameters to ensure the quality of rock drilling.

Rock Mass Geological Conditions

During the rock-drilling process, the actual drilling process has a crucial impact on drilling deviation, especially when drilling in rock formations with complex and variable geological conditions. Generally speaking, there is a close relationship between the degree of drilling deviation and the drilling depth, usually showing a positive correlation. That is, the greater the drilling depth, the greater the degree of drilling deviation tends to be. From practical experience, the drilling angle between the rock drill bit and the rock formation is an important factor that cannot be ignored.

When this angle is less than 15°, the drilling direction of the rock drill bit tends to be parallel to the rock joint surface. This is because in this case, the rock resistance acting on the rock drill bit during the drilling process is relatively evenly distributed in the direction parallel to the joint surface, making it easy for the rock drill bit to advance along the joint surface, resulting in a deviation in the drilling direction. For example, when drilling in a rock formation with a uniform texture, as long as the equipment performance is good and the operation is standardized, relatively accurate drilling can be achieved, effectively reducing the occurrence of deviation.

Construction Techniques and Tools

Construction Techniques

Construction techniques also play an important role in the rock-drilling process. In the actual construction process, if there are problems such as non-parallel construction procedures, mutual cross-influence, and poor coordination, these will restrict the rock-drilling efficiency. In the rock-drilling process, the parallelism of procedures is crucial. Reasonably arranging each procedure and reducing mutual interference can improve the overall operation efficiency. For example, if the construction procedures can be coordinated efficiently, time waste can be avoided and the tunneling speed can be accelerated. In addition, the quality of process coordination also affects the rock-drilling effect. Only when all links are closely coordinated can the rock-drilling operation be carried out smoothly.

Selection of Drill Rod

Suppose other drilling conditions are the same, the larger the diameter of the drill rod, the higher the straightness of the drill hole. In addition, the large-diameter drill rod can increase the rigidity of rock drilling tools, and ensure that the drill bit does not swing, which is conducive to the smooth discharge of cuttings from the hole. Therefore, a guide rod with a diameter larger than a drill rod is usually installed at the front of rock drilling tools to drill holes with a diameter larger than 127mm and is directly used to ensure that the hole is drilled with high straightness.

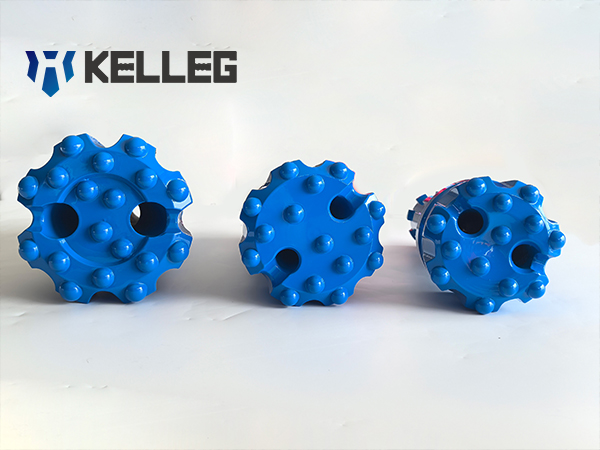

Selection of Rock Drill Bit

Rock drill bit structure and shape also affect drilling deviation. In drilling, regardless of rock drill bit shape, to obtain the best drilling straightness, the worn drill bit must be reground in time to restore the shape of the cemented carbide button and maintain the cemented carbide’s integrity. In particular, when grinding the spherical on the edge, not only the spherical, but also the steel of the skirt body should be ground, and the whole side of the skirt body should be ground down, instead of only grinding off the steel body near the spherical root.

Blasting and Methods

Blasting methods are also important factors affecting the rock-drilling effect. All parameters of the blasting scheme have a profound impact on rock drilling. Generally speaking, reasonable blasting methods, including cut-hole methods and charging methods, can effectively improve the rock-drilling effect, enhance the quality of rock fragmentation, and thus promote the efficient progress of tunneling work.

Labor Organization and Management

In rock-drilling projects, labor organization and management have a multi-faceted impact on the rock-drilling effect. For example, the configuration of the number of construction workers and equipment needs to be determined according to the actual construction situation. When there are too many workers and too little equipment, problems such as poor organizational coordination and non-standard handover are likely to occur. Conversely, if multiple types of equipment are blindly introduced but there are too few workers for the amount of equipment, due to the workers' unfamiliarity with the new equipment, problems such as untimely equipment maintenance, improper management methods, and non-standard operations will arise. These problems in labor organization and management will all harm the rock-drilling efficiency and the overall project effect.

Other factors

In addition to the above points, many other factors affect drilling. Although it is impossible to completely avoid drilling deviation, we can reduce the deviation through some methods so as not to affect the progress of the entire rock drilling project.

The specific method is as follows:

Use a drill rod with high hardness, good rigidity, and straightness, and make the diameter of the drill hole as close to the diameter of the drill rod as possible.

Use a new tubular guide rod to reduce the probability of the drill rod breaking.

Use rock drilling equipment with high drilling accuracy to reduce drilling deviation.

Ensure correct propulsion force, increasing the rotation speed of rock drilling tools can also reduce drilling deviation.

It can also reduce deviation by drilling shallow holes in sections.

Conclusion

In conclusion, the factors affecting rock drilling are multi-faceted, covering the construction environment, construction techniques, construction tools, blasting methods, labor organization and management, etc. These factors are intertwined and jointly affect the rock-drilling effect. In actual projects, only by comprehensively considering these factors, selecting appropriate equipment according to specific circumstances, optimizing the blasting scheme, and improving construction techniques can efficient and safe rock-drilling results be achieved and the rock-drilling project be smoothly promoted.