Down-the-hole (DTH) drilling tools play a critical role in underground mining operations. Powered by compressed air, a DTH hammer delivers high-energy impacts directly to the drill bit, enabling fast penetration and excellent performance in hard rock formations. Compared with conventional rotary drilling, DTH technology offers higher drilling efficiency, superior hole straightness, and reliable operation in complex geological conditions.

In underground metal mines, non-metal mines, and coal mines, DTH drilling tools are widely used for different types of boreholes. This article provides a detailed explanation of the major hole types, their characteristics, and recommended DTH configurations, helping engineers select the right tools for safer and more efficient underground development.

1. How DTH Drilling Tools Work

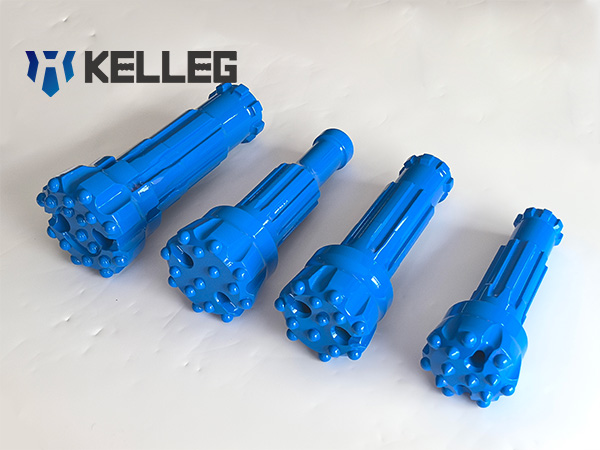

A DTH drilling system mainly consists of a hammer, drill bit, drill pipe, and coupling. Compressed air passes through the drill string into the DTH hammer, where it drives a piston that strikes the bit directly. This impact energy fractures the rock efficiently.

Unlike top hammer drilling, DTH tools deliver impact energy directly to the bit, minimizing energy loss and ensuring deeper, straighter holes even in hard rock formations.

2. Major Borehole Types Drilled with DTH Tools in Underground Mines

DTH drilling tools are used to create five primary categories of boreholes. Each type serves a distinct mining function and requires specific tool configurations.

2.1 Production Blasting Holes

Production blasting is the largest application of DTH drilling in underground mines. In underground mining, explosives are placed into these holes to fragment the rock and extract ore efficiently. DTH drills can produce hole diameters ranging from 90mm to over 200mm, reaching depths of tens of meters. The resulting straight holes ensure uniform blasting and higher ore recovery rates.

Typical Parameters

- Diameter: Ø89–Ø165 mm (medium-deep holes); Ø165–Ø254 mm (deep holes)

- Depth: 5–40 m (medium-deep), 40–100+ m (deep holes)

- Pattern: Fan-shaped or parallel drilling

- Spacing: 2.5–6 m depending on stope design

Application Scenario

Medium and deep blasting holes are drilled in stopes to fragment ore for extraction. Modern underground jumbos (e.g., Sandvik DD421) equipped with DTH modules drill long, straight holes that help ensure controlled blasting and high ore recovery.

Recommended DTH Configuration

- 1.5–2.5 MPa medium-pressure hammer

- Ø127 mm drill pipes

- Hard-rock DTH bit with spherical buttons

2.2 Rock Bolt Holes

To ensure the stability of tunnels and stopes, DTH drills are used to create holes for rock bolts and grouting. These reinforcement systems strengthen the rock mass and prevent collapses, enhancing overall mine safety.

Typical Parameters

- Diameter: Ø38–Ø51 mm

- Depth: 1.5–6 m

- Angle: Vertical or 15°–45° inclined

Application Scenario

Used for roadway and cavern support, especially where rock hardness or abrasiveness makes traditional top-hammer drilling inefficient.

Recommended DTH Configuration

- 0.5–0.7 MPa low-pressure hammer

- Ø22/25 mm hexagonal drill steel

- Small-diameter DTH bit

2.3 Exploration and Core Sampling Holes

Before mining begins, exploration holes are drilled to study geological formations and ore distribution. DTH tools are preferred for their fast drilling speed and accurate sampling, making them essential for geological surveys and resource evaluation.

Typical Parameters

- Diameter: Ø76–Ø127 mm

- Depth: 50–300 m

- Core Recovery Requirement: >85% with specialized core barrels

Application Scenario

Exploration holes are drilled horizontally or at an angle from internal drifts to verify mineralization, thickness, and grade continuity.

Recommended DTH Configuration

- High-pressure hammer

- Double-wall drill pipes

- DTH-compatible core bit and core barrel system

2.4 Dewatering and Pressure Relief Holes

Water accumulation in underground mines can cause instability and equipment damage. DTH drilling tools are used to create drainage or dewatering holes to remove excess water or test groundwater pressure and flow, preventing flooding incidents.

Typical Parameters

- Diameter: Ø89–Ø133 mm

- Depth: 20–150 m

- Angle: Upward drilling to reduce cuttings blockage

Application Scenario

- Gas drainage in coal mines

- Pre-drainage of water-bearing zones

- Pressure relief in high-stress rock masses

Recommended DTH Configuration

- High-pressure reverse-circulation hammer

- Ø114 mm casing advance system

- Bit designed for water-bearing strata

2.5 Ventilation Holes

Proper airflow is vital for underground mining safety. DTH tools are often used to drill large-diameter ventilation holes to improve air circulation, reduce dust, and remove harmful gases—providing a safer working environment for miners.

Technical Parameters

- Diameter: φ75–φ150 mm

- Depth: 10–80 m

- Pattern: Parallel holes, grouped holes, or connected to roadways

Applications

- Auxiliary Ventilation

- Local Ventilation

- Cross-Area Ventilation

- Emergency Ventilation

Recommended DTH Tools

- Medium–High Pressure DTH Hammer

- Large Air Flow Flushing System

- Ventilation Bit with Enhanced Wear Resistance

3. Key Advantages of DTH Drilling Tools

DTH systems offer several performance benefits that make them ideal for hard-rock underground environments:

3.1 High Impact Energy and Penetration Rate

A DTH hammer typically delivers 800–2500 blows per minute, with single-blow energy reaching 300–1500 joules, enabling rapid rock fragmentation even in high-strength formations.

3.2 Excellent Hole Straightness

Because the hammer is positioned directly behind the bit, the drill string remains stable. Hole deviation is often less than 1‰, making DTH ideal for deep-hole production and dewatering applications.

3.3 Strong Adaptability to Hard and Abrasive Rock

DTH achieves 0.5–2 m/min in formations with hardness f = 8–18. outperforming top hammer or rotary drilling in similar conditions.

3.4 Wide Range of Hole Diameters

Typical diameters range from Ø89 mm to Ø305 mm, with some systems capable of drilling holes up to Ø1000 mm for special applications.

4. Conclusion

In summary, DTH drilling tools in underground mining are primarily used for blastholes, ventilation holes, drainage holes, exploration holes, and reinforcement holes. Their ability to deliver powerful, precise, and efficient drilling makes them indispensable in modern mining operations.

If you are looking for reliable DTH drilling tools or hammers, KELLEG offers professional solutions to enhance your underground drilling performance with superior quality and durability.