Proper maintenance of Down-The-Hole hammers is essential for ensuring optimal performance, extending equipment lifespan, and minimizing costly downtime in mining, water well drilling, or construction projects. DTH hammers are robust tools designed for hard rock drilling, but without regular care, they can suffer from wear, reduced efficiency, or even failure. This guide provides practical maintenance tips tailored for mining professionals, equipment operators, and fleet managers to keep DTH hammers in top condition.

1. Conduct Regular Inspections

Routine inspections are the foundation of effective DTH hammer maintenance. Catching issues early prevents minor problems from escalating into major repairs.

- Visual Checks: Before and after each use, inspect the hammer for visible damage, such as cracks, dents, or worn threads. Pay close attention to the chuck, piston, and drill bit shank.

- DTH Drill Bit Condition: Examine the drill bit for excessive wear, chipped carbide buttons, or uneven grinding. Replace drill bits if they show significant damage to avoid stressing the hammer.

- Seals and O-Rings: Check seals and O-rings for wear or leaks, as these components are critical for maintaining air pressure and preventing contamination.

Tip: Create a daily inspection checklist and train operators to follow it consistently. Document findings to track wear patterns over time.

2. Clean Thoroughly After Use

Dirt, dust, and debris can accumulate inside the hammer, reducing efficiency and causing internal damage. Proper cleaning is vital, especially in abrasive environments.

- Flush the Hammer: After drilling, flush the hammer with clean water or a manufacturer-recommended cleaning solution to remove dust and debris from internal components.

- Clear Air Passages: Use compressed air to blow out any remaining particles in the air tubes and exhaust ports. Clogged passages can reduce impact energy and penetration rates.

- Avoid Harsh Chemicals: Use only approved cleaning agents to prevent corrosion of internal parts, such as the piston or cylinder.

Tip: Clean the hammer immediately after use to prevent debris from hardening, which can make cleaning more difficult.

3. Lubricate Properly

Lubrication reduces friction, minimizes wear, and protects against corrosion, especially in high-pressure or wet drilling conditions.

- Use the Right Lubricant: Choose a high-quality, manufacturer-recommended rock drill oil designed for DTH hammers. Avoid using general-purpose oils, which may not withstand high temperatures or pressures.

- Lubrication Frequency: Lubricate the hammer before each shift or as specified by the manufacturer. For example, Kelleg recommends 2–4 ounces of oil per hour of operation for most models.

- Check Lubrication System: Ensure the rig’s lubricator is functioning correctly and delivering a consistent oil flow to the hammer.

Tip: Monitor oil consumption during operation. Excessive or insufficient oil can indicate issues with the lubrication system or hammer seals.

4. Monitor Operating Conditions

Incorrect operating conditions can accelerate wear and damage the hammer. Pay attention to the following:

- Air Pressure: Operate the hammer within the recommended air pressure range (e.g., 10–25 bar for high-pressure hammers). Excessive pressure can damage internal components, while low pressure reduces efficiency.

- Rotation Speed: Maintain the manufacturer’s recommended RPM to prevent excessive DTH drill bit wear or hammer vibration. For example, a typical DTH hammer operates at 20–60 RPM for optimal performance.

- Feed Force: Apply consistent feed pressure to avoid overloading the hammer or causing it to “bounce” in the hole, which can lead to premature failure.

Tip: Train operators to monitor gauges and adjust settings based on real-time feedback from the drilling rig.

5. Store Properly

Proper storage prevents corrosion and damage when the hammer is not in use.

- Dry and Clean Storage: Store hammers in a dry, clean environment to prevent rust. Coat external surfaces with a light layer of oil before storage.

- Protect Threads: Use thread protectors on the hammer and DTH drill bits to prevent damage to connection points during storage or transport.

- Vertical Storage: Store hammers vertically to avoid stress on internal components and to prevent oil pooling in one area.

Tip: Keep a storage log to track when hammers are stored and inspected, ensuring they’re ready for use when needed.

6. Replace Worn Parts Promptly

Worn or damaged parts can compromise the hammer’s performance and lead to costly repairs.

- Replace DTH drill bits: Monitor DTH drill bit wear and replace them when carbide buttons are worn or damaged. A worn DTH drill bit reduces penetration rates and stresses the hammer.

- Check Internal Components: During scheduled maintenance, inspect internal parts like the piston, valve, and chuck for wear. Replace them as needed to maintain performance.

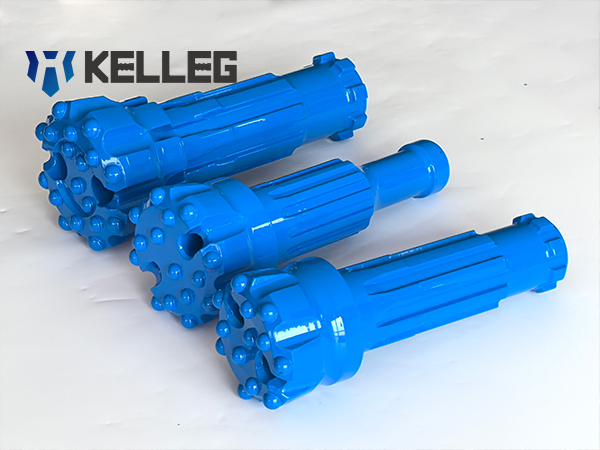

- Use OEM Parts: Always use original equipment manufacturer parts to ensure compatibility and reliability. For example, Kelleg’s OEM drill bits are designed to match their DTH hammers precisely.

Tip: Keep a stock of critical spare parts, such as drill bits, seals, and O-rings, to minimize downtime during repairs.

7. Schedule Professional Servicing

While daily maintenance can be handled on-site, periodic professional servicing ensures the hammer operates at peak performance.

- Manufacturer Servicing: Follow the manufacturer’s recommended service intervals (e.g., every 200–300 hours of operation). Professional servicing includes disassembling, cleaning, and inspecting internal components.

- Performance Testing: Have the hammer tested for impact energy, air consumption, and penetration rate to ensure it meets specifications.

- Record Keeping: Maintain detailed service records to track maintenance history and identify recurring issues.

Tip: Partner with a reputable service provider who specializes in DTH hammers to ensure high-quality repairs and maintenance.

Conclusion

Regular maintenance of DTH hammers is crucial for maximizing productivity and minimizing operational costs in mining and drilling projects. By conducting routine inspections, cleaning thoroughly, lubricating properly, monitoring operating conditions, storing correctly, replacing worn parts, and scheduling professional servicing, you can extend the lifespan of your DTH hammer and ensure reliable performance. Implement these tips consistently to keep your equipment in top shape and your projects on track.