Conducting pile driving construction under complex and variable geological conditions poses a significant challenge to engineering technology. Especially when encountering obstacles such as hard interlayers or isolated rocks, traditional hammering methods often fail to achieve effective pile driving and may even lead to pile fatigue damage, making it difficult to ensure construction efficiency and quality. However, with technological advancement, an innovative solution has emerged—using Down-the-Hole (DTH) hammers to assist in driven pipe pile construction. This approach offers a high-efficiency, precision-driven alternative that helps tackle difficult subsurface conditions. So, how exactly does the DTH hammer contribute to this process?

Working Principle of the DTH Hammer

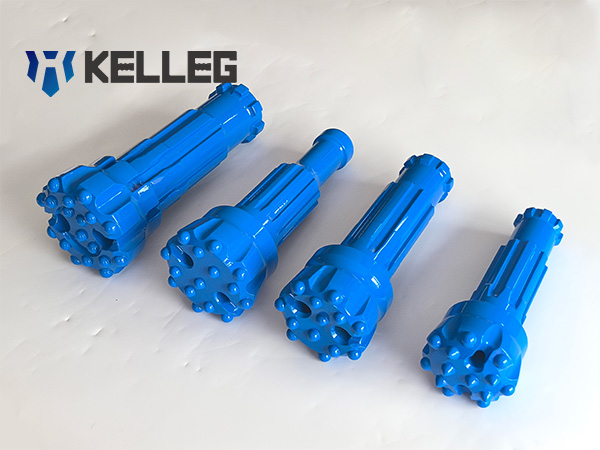

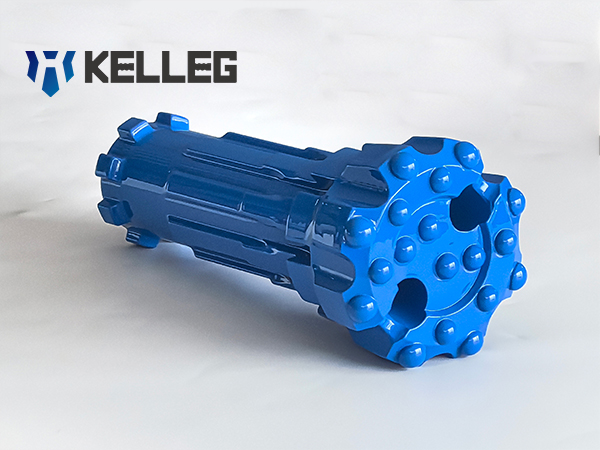

A pneumatic DTH hammer is a rock-drilling device powered by high-pressure air. The hammer drives a piston to perform high-frequency reciprocating motion, transferring energy to the drill bit. Under the combined action of drill pressure and torque, the bit impacts and fractures soil or rock layers. Simultaneously, compressed air clears debris from the borehole, keeping the drilling path clean and stable.

Key Roles of the DTH Hammer in Driven Pipe Pile Construction

Penetrating Hard Interlayers and Boulders

When encountering dense gravel layers or isolated rocks, traditional driving methods often fail. A DTH hammer, with its powerful impact energy and torque, can efficiently break through these obstacles, facilitating smooth pile advancement.

Reducing Soil Displacement (Bulging Effect)

Soil displacement during pile driving can cause ground upheaval and pose risks to nearby structures, especially in urban areas. Pre-drilling with a DTH hammer creates an initial borehole, relieving pore pressure and minimizing ground displacement.

Improving Construction Efficiency

Pneumatic down-the-hole hammers offer high construction efficiency and significant hole-drilling results. Compared to traditional long-spiral drilling rigs or rotary drilling rigs, down-the-hole hammers are faster and more efficient at penetrating hard layers and isolated rocks.

Ensuring Pile Integrity and Load-Bearing Performance

Pre-boring with a DTH hammer helps maintain pile straightness and alignment while reducing driving resistance, ultimately enhancing the quality and bearing capacity of the foundation.

Advantages of DTH-Assisted Pile Driving

Excellent Adaptability

DTH hammers perform well in various geological conditions, including hard rock and gravelly formations with scattered boulders. Their versatility makes them suitable for a wide range of construction projects.

Low Noise and Vibration

Compared to traditional impact pile drivers or rotary drilling rigs, DTH hammers generate less noise and vibration, making them ideal for environmentally sensitive or densely built environments.

Easy Operation and Maintenance

The pneumatic down-the-hole hammer is relatively easy to operate, and construction personnel can quickly learn how to use it after training. At the same time, the equipment is also relatively easy to maintain, reducing the failure rate and downtime during construction.

Conclusion

In complex geological settings, using DTH hammers to assist driven pipe pile construction proves to be an efficient, reliable solution. It offers significant advantages in penetrating hard layers and isolated rocks, reducing soil displacement effects, improving construction efficiency, and ensuring pile foundation quality, thereby providing strong support for the smooth progress of construction projects. This technology not only significantly enhances construction efficiency and effectively controls soil displacement effects but also ensures the quality and safety of pipe pile construction, opening up new avenues for pipe pile engineering in complex geological conditions. As technology continues to evolve and expand its applications, DTH hammers-assisted pile driving is poised to become an essential method in modern foundation engineering—helping the industry achieve higher performance standards and more sustainable outcomes.