Definition of Air Reverse Circulation (RC) Drilling

Air Reverse Circulation (RC) drilling is a rotary percussion drilling method that uses compressed air to transport rock cuttings from the drill bit to the surface through a dual-wall drill rod system. Unlike conventional air drilling, where cuttings travel upward in the annulus between the drill rod and the borehole wall, RC drilling reverses the airflow direction by forcing the cuttings to move upward through an inner tube inside the drill string.

At the surface, the cuttings are discharged into a cyclone separator, where they are collected as dry, representative rock samples. This controlled sample recovery process significantly reduces contamination and mixing between geological layers, making RC drilling especially suitable for mineral exploration and grade control programs.

RC drilling typically combines:

- A down-the-hole (DTH) hammer

- A dual-wall RC drill rod

- A high-capacity air compressor and booster

- A cyclone and sample collection system

Technical Overview of Air Reverse Circulation Drilling

Air Reverse Circulation (RC) drilling technology can be classified into different technical systems based on circulation mechanism and application scenarios. The two most representative and widely applied systems are:

- Air-Lift Reverse Circulation Drilling Technology

- Air Reverse Circulation Continuous Sampling Technology

Both technologies are designed to improve sample recovery quality, drilling efficiency, and adaptability to complex geological conditions, but they serve different depth ranges and exploration objectives.

Air-Lift Reverse Circulation Drilling Technology

Air-lift reverse circulation drilling is based on the air-lift pump principle. Compressed air is injected into the drilling system, where it mixes with the flushing fluid inside the drill string. As the air expands, it forms a low-density gas–liquid mixture, creating a pressure difference between the fluid columns inside and outside the drill pipe.

Driven by this pressure differential, the flushing fluid carries rock cuttings (or core fragments) upward through the center of the drill string, achieving true reverse circulation.

Key System Components

From top to bottom, the downhole drilling assembly consists of:

- High-pressure air distribution device

- Dual-wall drill rods

- Air–water mixing device

- Reverse circulation drill bit

At the surface, a dedicated sample separation system processes the returned three-phase flow of gas, liquid, and solid, enabling effective rock sample recovery and collection.

This technology is particularly suitable for deep-hole hard rock drilling, where conventional circulation methods face limitations in efficiency and sample integrity.

Air Reverse Circulation Continuous Sampling Technology

Air reverse circulation continuous sampling technology is an advanced mineral exploration sampling method, primarily applied in exploration drill holes up to 600 meters in depth.

The downhole drilling assembly typically includes:

- Dual-channel air–water swivel or air box

- Outer-flat dual-wall drill rods

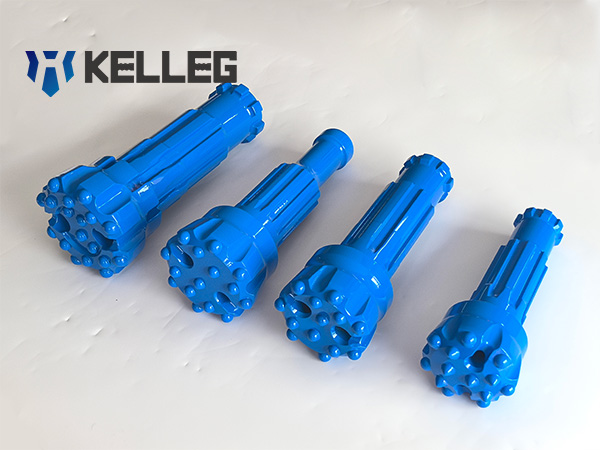

- Reverse circulation pneumatic DTH hammer

- Bottom-hole flow diverter (air RC adapter or cross adapter)

- Drill bit

At the surface, a cyclone separator reduces the velocity of the high-speed air stream carrying rock cuttings and efficiently separates the samples. A sample splitter then divides the samples according to geological requirements, ensuring representative and consistent sampling for analysis.

This system enables continuous, real-time sample collection during drilling, significantly improving exploration efficiency and data reliability.

While both air-lift RC drilling and air RC continuous sampling technologies share the same reverse circulation principle, their structural design, operational focus, and performance characteristics differ depending on depth, formation conditions, and sampling objectives. These differences are reflected in their distinct technical characteristics, which are outlined below.

Technical Characteristics of Air Reverse Circulation Drilling Technologies

Technical Characteristics of Air-Lift Reverse Circulation Drilling

High-Strength Dual-Wall Drill Tools for Deep Drilling

A high-strength dual-wall drilling system has been developed for deep-hole applications, with pressure resistance increased to over 30 MPa, effectively overcoming traditional depth limitations.

Key innovations include:

- Optimized inner-pipe sealing sleeves made of high-performance alloy steel to enhance wear resistance

- Introduction of a tapered guiding and centering structure to improve concentricity between inner and outer pipes

- Reduced uneven wear of outer pipe limit structures

- Optimized sealing components to improve radial sealing reliability

These improvements collectively raise the pressure-bearing capacity of dual-wall drill rods to above 30 MPa for the first time.

High Rig Compatibility and Simple System Integration

The technology is highly adaptable and can be used with:

- Full hydraulic power-head rigs

- Top-drive rigs

- Rotary table rigs

Without modifying the drilling rig structure, a compact, reliable, and well-sealed high-pressure air distribution device is used. The system employs tapered threaded connections and an internal inner tube to form dual flow channels, which are sealed using reliable rotary sealing mechanisms.

High Efficiency in Deep Hard Rock Drilling

The expansion work generated by the air-lift effect significantly increases the upward velocity of rock cuttings, keeping the borehole bottom clean and preventing repeated crushing of cuttings.

Compared with conventional mud positive circulation drilling:

- Drilling efficiency increases by more than 30%

- Circulation is unaffected by fractures or karst cavities in the target formation

- No drilling mud is used, eliminating formation contamination risks

Environmentally Friendly Three-Phase Flow Treatment

The returned gas–liquid–solid flow is centrally processed at the surface. Dedicated sample separation equipment enables efficient three-phase separation, improving site cleanliness and environmental performance while ensuring reliable sample collection.

Technical Characteristics of Air Reverse Circulation Continuous Sampling Technology

Optimized Dual-Wall Drill Rod Structure

The outer pipe joint has the same diameter as the pipe body, resulting in a simple structure with reliable sealing, suitable for complex formations.

Design features include:

- Internal thickening and upsetting of the outer pipe to enhance friction welding strength

- Small-taper threaded connections to allow large internal passages for cuttings return

- Outer flat structure enabling full-hole drilling, reducing rotational resistance

- These features help maintain borehole verticality and support fast drilling with small-diameter holes.

Modular Bottom-Hole Tool Combinations for Different Formations

Different bottom-hole flow diverters and rock-breaking tools are developed to match varying formation characteristics.

Examples include:

- Air RC adapters for sampling drag bits and tricone sampling bits

- Cross adapters designed for conventional pneumatic DTH hammers

- High-pressure air flows through the annular space of the dual-wall drill rod to the bottom-hole rock-breaking tools, enabling efficient continuous sampling across diverse geological conditions.

Dedicated Surface Sample Handling System

Specialized surface equipment—including cyclone separators and sample splitters—ensures efficient collection of returned cuttings and uniform sample splitting according to geological standards, improving the accuracy of sample analysis.

Integration of RC DTH Hammer Drilling with Continuous Sampling

By integrating reverse circulation DTH hammer drilling into the continuous sampling process:

- Drilling efficiency is significantly increased

- Sampling is performed simultaneously with drilling

This eliminates downtime associated with conventional coring operations, such as stopping drilling, retrieving core barrels, and pulling rods, greatly improving overall sampling efficiency.

High-Speed Sample Return and Borehole Stability

Rock cuttings return through the center of the dual-wall drill string at speeds of up to 20 m/s. The high-velocity airflow rapidly transports cuttings to the surface, preventing sample mixing between depth intervals and enabling fast, accurate identification of mineralized zones.

At the same time, circulation occurs within the annular space and center channel of the dual-wall drill rod, avoiding direct erosion of the borehole wall. This maintains borehole stability and reduces the risk of downhole accidents.

Conclusion

Air Reverse Circulation (RC) drilling has become a critical technology in modern mineral exploration due to its unique ability to balance drilling efficiency, cost control, and sample reliability. By utilizing a reverse airflow system within dual-wall drill rods, RC drilling delivers clean, representative samples while maintaining high penetration rates, making it especially valuable for early-stage exploration, infill drilling, and grade control programs.

Equally important is the choice of high-quality RC drilling tools and experienced suppliers. Well-designed dual-wall drill rods, reliable RC hammers and drill bits, and robust surface separation systems are essential to achieving consistent performance and minimizing downtime. Working with suppliers that possess strong engineering capabilities, proven field experience, and comprehensive technical support can significantly enhance drilling efficiency, sample accuracy, and overall project success.