Introduction

Down-the-hole (DTH) hammers are essential tools in modern rock drilling, widely used in mining, quarrying, water well drilling, and foundation construction projects. Operating directly at the bottom of the borehole, a DTH hammer delivers high-frequency impact energy straight to the drill bit, making it especially effective in hard and abrasive rock formations where drilling efficiency and hole accuracy are essential.

Because the hammer operates under extreme conditions—high impact loads, repeated stress cycles, abrasive cuttings, and continuous air pressure—its construction quality plays a decisive role in overall drilling performance. Unlike surface drilling tools, any weakness in a DTH hammer’s internal structure is amplified during operation, leading to rapid wear, energy loss, or even catastrophic failure.

Manufacturing quality directly affects the penetration rate by determining how efficiently impact energy is generated, transferred, and converted into rock-breaking force. Precise machining of internal components ensures smooth piston movement and minimal air leakage, while optimized airflow design maximizes energy output with lower air consumption. Even small deviations in tolerances can reduce impact efficiency and slow drilling progress.

At the same time, the service life of a DTH hammer is largely defined by material selection, heat treatment, and assembly accuracy. High-quality alloy steels, properly controlled heat treatment processes, and consistent quality control help the hammer resist fatigue, impact cracking, and abrasive wear. In contrast, poor manufacturing practices often result in premature failures, increased downtime, and higher cost per drilled meter.

For drilling contractors and mining operators, understanding the DTH hammer construction process is therefore not just a technical detail—it is a key factor in selecting reliable tools, optimizing drilling performance, and achieving long-term cost efficiency.

Structure of a Down-the-Hole (DTH) Hammer

A down-the-hole (DTH) hammer is a precision-engineered pneumatic tool designed to deliver high-impact energy efficiently at the bottom of the borehole. Its performance and reliability depend on the coordinated function of multiple internal components. A typical DTH hammer consists of the following key parts:

Outer Casing (Outer Sleeve):

Encloses and protects all internal components while withstanding high external pressure, impact loads, and abrasive conditions during drilling.

Check Valve:

Regulates compressed air flow into the hammer, ensuring correct pressure distribution and stable piston operation during each impact cycle.

Spring:

Provides restoring force to assist valve movement and maintain consistent timing of the air distribution system.

Valve Rod (Gas Distribution Rod):

Controls the inlet and exhaust of compressed air through internal air ducts and exhaust ports, enabling precise switching between the forward and return strokes of the piston.

Cylinder

Houses the piston and forms the front air chamber and rear air chamber, which alternately control the piston’s return and impact strokes through air pressure changes.

Piston:

The core energy-transmitting component, driven by compressed air to perform high-frequency reciprocating motion and deliver impact energy directly to the drill bit.

Guide Sleeve:

Guides piston movement, maintains axial alignment, and reduces side wear to ensure stable operation and long service life.

O-Rings:

Critical sealing elements that prevent air leakage, maintain pressure efficiency, and protect internal components from contamination.

Retaining Ring:

Secures internal parts in position, maintaining structural integrity under repeated impact and vibration.

Front Joint (Chuck):

Connects the hammer to the DTH drill bit and transmits impact energy from the piston to the bit with minimal energy loss.

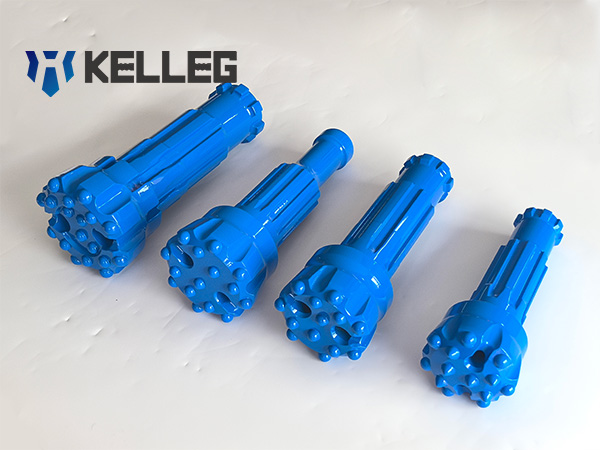

DTH Drill Bit:

Directly contacts and fractures the rock, converting impact energy into efficient rock-breaking action.

This integrated structure allows the DTH hammer to deliver powerful, consistent impacts with high energy efficiency, making it a preferred drilling solution for hard rock applications in mining, quarrying, water well, and construction projects.

Design and Engineering Considerations Before Manufacturing

Before a DTH hammer enters production, careful design and engineering are essential to ensure optimal drilling performance, energy efficiency, and durability. Decisions made at this stage directly influence penetration rate, air consumption, and overall service life.

Impact Energy and Air Efficiency Design

The primary objective of DTH hammer design is to maximize impact energy while minimizing compressed air consumption. Engineers must determine the optimal piston stroke length, diameter, and operating pressure to deliver sufficient impact force without wasting air. Efficient energy conversion not only improves penetration rates but also reduces compressor load and operating costs.

Internal Airflow Channel Optimization

Internal air channels and exhaust ports are designed to ensure smooth, rapid air distribution between the front and rear chambers of the hammer. Well-optimized airflow reduces pressure loss, improves piston response time, and stabilizes impact frequency. Poor airflow design can lead to energy loss, irregular impacts, and increased wear of internal components.

Compatibility with DTH Drill Bits

A DTH hammer must be precisely matched with the corresponding drill bit in terms of shank design, spline geometry, and diameter tolerance. Proper compatibility ensures effective transfer of impact energy from the piston to the bit, reduces stress concentration, and prevents premature wear or failure of both the hammer and the bit.

Balancing Impact Frequency and Piston Weight

Impact frequency and piston weight must be carefully balanced according to drilling conditions. A heavier piston delivers higher single-impact energy, which is advantageous in hard rock, while a lighter piston allows higher impact frequency and smoother operation in medium formations. An optimized balance ensures stable drilling performance across a wide range of geological conditions.

Raw Material Selection for DTH Hammers

Material selection is a critical factor in determining the durability, reliability, and cost-effectiveness of a DTH hammer. Since the hammer operates under repeated high-impact and high-stress conditions, only carefully selected alloy steels can meet performance requirements.

Common Alloy Steel Grades Used

- Pistons: High-strength alloy steels with excellent fatigue resistance and impact toughness to withstand repeated удар loads.

- Cylinders: Wear-resistant alloy steels with good hardenability to maintain internal surface integrity and dimensional stability.

- Chucks (Front Joints): Tough, impact-resistant steels capable of absorbing shock while maintaining precise bit engagement.

Key Material Requirements

- High Fatigue Strength: To resist cracking under millions of impact cycles.

- Wear Resistance: To minimize abrasion from rock cuttings and internal friction.

- Impact Toughness: To prevent brittle failure under sudden load changes.

How Material Quality Affects Hammer Lifespan

High-quality raw materials with consistent chemical composition and controlled impurity levels respond better to heat treatment, resulting in uniform hardness and reliable core toughness. In contrast, inferior materials often lead to uneven wear, micro-cracking, and premature failure, significantly reducing hammer service life and increasing drilling costs.

By combining sound engineering design with proper material selection, manufacturers can produce DTH hammers that deliver stable performance, long service life, and lower cost per drilled meter.

Precision Machining and Forming Processes

Forging vs. Bar Stock Machining

Key load-bearing components such as pistons and cylinders are often forged to improve grain structure, density, and impact strength. Forging enhances fatigue resistance and reduces the risk of internal defects. Bar stock machining, on the other hand, offers higher dimensional consistency and is commonly used for parts requiring tight tolerance control. High-quality manufacturers select the process based on component function rather than cost alone.

CNC Turning and Milling for Tight Tolerances

Advanced CNC turning and milling are essential to achieve precise diameters, concentricity, and alignment of internal components. Tight tolerances ensure correct piston-to-cylinder clearance, stable airflow switching, and minimal energy loss during operation. Even minor deviations can cause air leakage, unstable impacts, or accelerated wear.

Internal Bore and Airflow Channel Accuracy

The accuracy of the internal bore and airflow channels determines how efficiently compressed air is distributed within the hammer. Smooth, correctly sized air passages reduce pressure loss and ensure fast response during piston stroke reversal. Poorly machined air channels can lead to uneven impact energy and reduced drilling performance.

Importance of Surface Finish for Piston Movement

Surface finish inside the cylinder and on the piston directly affects friction, heat generation, and wear. A finely finished surface allows smooth piston movement, reduces seizure risk, and extends component life under high-frequency impact conditions.

Heat Treatment Process in DTH Hammer Manufacturing

Carburizing, Nitriding, Quenching, and Tempering

Different components require different heat treatment methods. Carburizing and nitriding are commonly used to create a hard, wear-resistant surface layer, while quenching and tempering improve overall strength and toughness. Selecting the correct process depends on component function and operating stress.

Target Hardness Zones for Different Components

- Pistons: High surface hardness with sufficient core toughness to withstand repeated impact loads.

- Cylinders: Wear-resistant internal surfaces with stable dimensional properties.

- Chucks and Front Joints: Tough cores combined with hardened contact surfaces to resist impact and abrasion.

Surface Treatment and Wear Protection

Shot Blasting and Polishing

Shot blasting removes surface impurities and improves surface uniformity, while polishing reduces friction and enhances component fit during assembly.

Surface Hardening for Wear Zones

Critical wear areas such as the chuck, bit interface, and internal sliding surfaces are often surface-hardened to resist abrasion and prolong operational life.

Corrosion Protection for Harsh Environments

Protective coatings or surface treatments are applied to reduce corrosion in wet, acidic, or chemically aggressive drilling conditions, helping maintain structural integrity over time.

Quality Control

Dimensional Inspection and Tolerance Checks

Precision measuring instruments are used to verify critical dimensions, clearances, and concentricity, ensuring all components meet design specifications.

Hardness and Metallographic Testing

Hardness testing confirms that heat treatment targets have been achieved, while metallographic analysis verifies microstructure quality, case depth, and absence of internal defects.

Air Pressure and Impact Performance Testing

Functional tests under simulated operating conditions evaluate air consumption, impact frequency, and energy output to ensure stable and efficient performance.

How to Choose a Reliable DTH Hammer Manufacturer

Selecting a reliable DTH hammer manufacturer is as important as choosing the right hammer model. The manufacturer’s technical capability, process control, and service support directly determine product consistency, drilling performance, and long-term operating cost.

Manufacturing Transparency

A trustworthy manufacturer is willing to clearly explain its production processes, from raw material sourcing and machining to heat treatment and final testing. Transparent manufacturers typically provide detailed technical documentation, process descriptions, and performance data, allowing customers to understand how product quality is achieved rather than relying solely on specifications or price.

Quality Certifications and Testing Standards

Reliable manufacturers follow recognized quality management systems and industry testing standards. Certifications such as ISO-based quality systems, along with documented inspection procedures, hardness testing, and performance validation, demonstrate a commitment to consistent manufacturing quality and traceable production control.

Technical Support and Customization Ability

Strong technical support is a key indicator of a professional manufacturer. The ability to recommend suitable hammer models, adjust designs for specific rock formations, compressor capacities, or drilling conditions, and provide after-sales technical guidance adds significant value. Customization capabilities also reflect the manufacturer’s engineering strength and practical drilling experience.

By evaluating these factors together, drilling contractors and mining operators can identify DTH hammer manufacturers that offer not only competitive products but also long-term reliability, performance stability, and professional technical partnership.

Conclusion

The construction process of a down-the-hole (DTH) hammer is the foundation of its performance, reliability, and service life. From engineering design and material selection to precision machining, heat treatment, surface protection, and final testing, every manufacturing step directly influences impact energy efficiency, penetration rate, and resistance to wear and fatigue. A well-designed and properly manufactured DTH hammer delivers consistent impact power, stable operation, and predictable performance across demanding drilling conditions.

For drilling contractors and mining operators, the most effective purchasing decisions are made by evaluating how a DTH hammer is manufactured—not just the specifications listed on a datasheet. By focusing on construction quality, process control, and manufacturer capability, buyers can select tools that deliver long-term value, operational reliability, and sustainable drilling performance.