Introduction — Why Low-Headroom Pile Driving is Difficult

Low-headroom or restricted-height construction refers to foundation and piling work carried out in spaces where the available vertical clearance is limited. In these environments, standard piling and drilling rigs cannot be fully erected or operated, which creates significant technical and logistical challenges for contractors and equipment suppliers.

Low-headroom piling is commonly required in projects such as:

- Metro and underground railway stations where piling must be completed beneath existing structures

- Tunnels, where the height of the excavation or lining restricts machine operation

- Under-bridge piling works, especially during structural reinforcement or widening projects

- Underground caverns and mining chambers where space is narrow, and access is difficult

- Industrial plants and brownfield sites where machinery must operate inside existing buildings

In these working environments, contractors must deal with multiple constraints at the same time. Machine height is limited, meaning conventional rotary drilling rigs, cranes, and pile drivers cannot be installed or operated safely. Ventilation conditions are often poor, increasing the risks associated with dust, fumes, and engine exhaust. Visibility is restricted, which raises operational safety risks and requires precise equipment control. On top of this, standard piling methods generate vibration, noise, or structural disturbance, which may not be acceptable in sensitive underground or urban environments.

Because of these limitations, many conventional piling technologies become inefficient, unsafe, or completely unsuitable for low-headroom applications. This has driven the industry to search for alternative drilling and pile-driving technologies that can deliver high penetration efficiency, strong rock-breaking capability, low vibration, and compact equipment dimensions.

One of the effective solutions that has emerged is cluster-type circumferential Down-the-Hole (DTH) hammer technology — a system specifically engineered to achieve large-diameter pile drilling in restricted-height working conditions.

What Is Cluster-Type Circumferential DTH Hammer Technology?

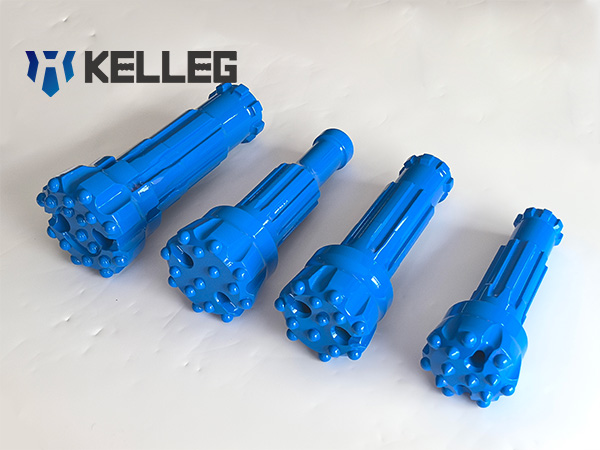

Cluster-type circumferential Down-the-Hole (DTH) hammer technology is an advanced drilling solution designed for low-headroom and hard-rock environments, enabling efficient pile driving where conventional rigs cannot operate. This technology integrates multiple functional systems into a compact and highly efficient drilling unit, providing both high penetration performance and enhanced operational safety.

Key Components and Function

The cluster-type circumferential DTH hammer consists of several interconnected systems, each designed to optimize drilling performance:

1. Air Supply System

- Delivers high-pressure compressed air to the hammer

- Powers the hammer body to convert air energy into percussive force

- Ensures consistent drilling speed even under varying rock hardness

2. Cuttings Removal System

- Efficiently removes rock debris from the borehole

- Reduces dust and prevents clogging

- Maintains stable drilling conditions in confined spaces

3. Rock Breaking System

- The hammer body is engineered to fracture rock effectively

- Converts air energy into impact energy for high-efficiency penetration

- Works in combination with a circumferential drill rod array to maximize bore coverage

4. Core Splitting System

- Allows partial or complete splitting of the rock core

- Facilitates extraction in cases where full coring is not required

- Improves overall drilling efficiency in heterogeneous rock formations

5. Core Retrieval System

- Includes core-taking drill components and specialized grippers for rock fragments

- Simplifies the removal of rock cores or debris from the borehole

- Reduces operational downtime and improves safety

Main Structural Components

- Hammer Body – Converts air pressure into percussive energy to break rock

- Circumferential Drill Rods – Firmly connected around the hammer to provide structural stability and uniform drilling

- Oil Atomizer – Allows real-time lubrication and monitoring to reduce wear

- Core Drill / Grippers – For rock fragment or core extraction

- Dust & Debris Collector – Minimizes dust pollution and improves environmental safety

How the Technology Works

- Multiple hammers are arranged in a circular “cluster” around a central axis.

- Each hammer impacts simultaneously, forming a large-diameter borehole even in tight spaces.

- Air-driven percussive energy breaks rock efficiently, while the debris removal system keeps the borehole clean.

- Core-splitting and retrieval systems allow precise extraction of rock samples or debris without interrupting operations.

Advantages of Cluster-Type Circumferential DTH Hammer Technology

- Compact layout suitable for restricted-height environments

- High drilling efficiency in hard rock conditions

- Reduced vibration and structural disturbance

- Precise borehole control for high-quality piles

- Enhanced safety, lower dust, and improved operator monitoring

Construction Process

The low-headroom pile construction process involves three main stages: drilling, reinforcement cage installation, and concrete pouring. Each stage is carefully designed to maximize efficiency, ensure safety, and maintain high-quality piles under restricted-height conditions.

Borehole Drilling

Equipment Setup

- Alignment: Position the drilling rig so that the DTH hammer cluster is perfectly aligned with the pile center, ensuring an accuracy within 20 mm.

- DTH Hammer Installation: Using a low-headroom crane, lift and place the DTH hammer into the rotary drilling rig. Secure the hammer body with the full-rotation main clamping system.

- Drill Rod Assembly: Attach the first drill rod section with the splitting device to the hammer top, tighten bolts, and connect all air and lubrication lines.

- System Testing: Test all functions and movements of the hammer and drill system. Use the rig leveling device and a plumb line to verify vertical alignment before starting the hammer.

Drilling Procedure

- Sequential Rod Installation: Drill until the bolt hole of the first drill rod section approaches the top of the rotary rig. Stop drilling and detach the air hose. Install the second drill rod section using the low-headroom crane, reconnect the air hose, and continue drilling.

- Intermediate Core Extraction: When approximately 2.4 m of rock remains, stop drilling. Activate the splitting device to break the rock core at the hammer top. Remove the rock core using the core drill and crane.

- Continuous Drilling: Raise the hammer slightly using the rotary rig clamp, connect the next drill rod section, and repeat the process until the target depth is reached.

- Borehole Cleaning & Verification: Clear all cuttings, measure borehole depth, and verify verticality. Disconnect the hammer air supply and remove drill rods section by section. Move the rig to the next pile location to repeat the process.

Reinforcement Cage Installation

- Prefabrication: Reinforcement cages are pre-manufactured in 2.5 m sections, with mechanical sleeve connections staggered by 50 cm to maintain structural continuity. All stirrup and main bar connections are welded for maximum strength.

- Assembly in Borehole: Place the first cage section into the borehole using a cage work platform. Align and correct the section using an electric hoist. Continue installing subsequent sections until the cage reaches the borehole top.

- Temporary Support: Use 25 mm diameter rebars through the base of the reinforcing hoops for temporary stabilization at the pile top.

Concrete Pouring

- Concrete Type & Delivery: Use C35 ready-mix concrete delivered from a centralized batching plant. Transport concrete via dump trucks or pumps to the borehole. For long boreholes, use a series-connected chute system to ensure the free-fall height does not exceed 2 m.

- Layered Placement: Place concrete in layers of 40–60 cm thickness. Layer thickness must not exceed 1.25 times the effective depth of the vibrator. Use an internal-insertion vibrator for compaction.

- Vibration & Safety: Operators descend into the borehole with safety harnesses to vibrate concrete properly, ensuring uniform consolidation. Pour the pile top slightly above the design level (+10 cm) to prevent voids.

Construction Monitoring

- Vibration & Noise Monitoring: Low-headroom pile rigs produce high-frequency vibrations, which may affect surrounding structures. Continuous monitoring of vertical and horizontal displacements, vibration levels, and noise is essential.

- Baseline Measurement: Conduct initial measurements before excavation to establish reference points.

- Ongoing Monitoring: Track displacement and deformation during drilling and pile construction. Stop monitoring after vertical and horizontal displacements stabilize and converge, following project approval.

Construction Quality Assurance Measures

Ensuring high construction quality is essential when working in low-headroom pile environments, where restricted space and precision requirements pose unique challenges. Quality control begins during site preparation and continues throughout drilling, reinforcement installation, and concrete pouring.

Pre-Construction Preparation

- Pile Center Surveying: Use a total station to measure and mark pile center positions according to design requirements. The deviation of pile center positions must not exceed 30 mm.

- Equipment and Track Alignment: Based on the pile center, precisely position the low-headroom pile rig, crane, and full-casing rotary drilling rig tracks. Measurement accuracy should be within **10 mm**. Mark alignment lines clearly on the track base plates.

- Base Plate Installation: Lay the base plates according to track positioning dimensions and use leveling shims underneath to ensure stability. To prevent displacement during operations, anchor the plates on both sides using anchor rods. Weld the rods to the steel plates for additional stability, maintaining an anchor spacing of 2 m.

Low-Headroom Pile Drilling Stage

- Hammer and Drill Alignment: Center the cluster-type circumferential DTH hammer over the borehole with an alignment tolerance of within 20 mm.

- Equipment Connection and Testing: Lift the hammer to the rotary drilling rig using a low-headroom crane. Connect all air, lubrication, and control lines, and perform comprehensive functional tests for the entire system.

- Verticality Adjustment: Use the rotary rig leveling device to adjust drill verticality, then re-check with a plumb line to confirm precise alignment before starting drilling operations.

- Ongoing Monitoring During Drilling: During excavation, repeatedly measure borehole verticality, diameter, and depth. Protect the pile location reference points during measurement, ensuring all parameters meet design specifications and relevant construction standards.

Conclusion

Cluster-type circumferential DTH hammer technology offers significant efficiency advantages for pile driving in low-headroom or confined environments. Its compact design, high penetration capability, and precise borehole control make it ideally suited for projects where conventional drilling equipment cannot operate safely or effectively.

Beyond technical performance, selecting a reliable supplier is critical to ensure consistent equipment quality, technical support, and long-term operational reliability. High-quality manufacturing and responsive service reduce downtime, improve project outcomes, and enhance overall safety.

For contractors and engineers frequently working in restricted-height piling environments, adopting cluster-type circumferential DTH hammer systems can significantly improve drilling efficiency, reduce operational risks, and enhance the quality of pile construction.