Introduction

Pressure testing pipes is used to monitor and verify the stability, stress conditions, and sealing performance of underground structures, pipelines, and drilling systems. These pipes are installed into pre-drilled boreholes so that pressure, flow, or structural behavior can be accurately measured during construction or operation.

They are commonly used in industries such as:

- Mining and underground excavation

- Tunneling and metro construction

- Geotechnical and slope stabilization projects

- Oil and gas development

- Hydrogeology and groundwater monitoring

- Water well drilling and pipeline testing

Pain Points and Challenges of Traditional Pressure Testing Pipe Installation Methods

Before the widespread use of Down-the-Hole (DTH) hammer technology, pressure testing pipes was usually installed using conventional rotary drilling or top-hammer drilling methods. While these methods are still common in many projects, they often face several technical challenges — especially in hard rock, fractured formations, or deep drilling environments.

Borehole Deviation and Poor Directional Control

Traditional drilling methods transfer impact energy from the top of the drill string down to the bit. As the drill string becomes longer, vibration and bending increase, making it difficult to maintain a straight borehole.

This often results in:

- Borehole deviation

- Misalignment between the pipe and the intended testing position

- Increased difficulty in inserting and positioning the testing pipe

Even a small deviation can cause inaccurate sealing and unreliable monitoring results.

Unstable Borehole Walls and Collapse Risk

In fractured or soft formations, traditional drilling methods may cause strong lateral vibration. This increases the risk of:

- Hole wall collapse

- Enlargement of the borehole

- Irregular borehole shape

When this happens, pressure testing pipes cannot be firmly supported, and sealing becomes difficult, directly affecting testing accuracy.

Limited Depth and Efficiency in Hard Rock

In hard rock or abrasive formations, rotary drilling efficiency drops significantly. Problems include:

- Slow penetration rate

- Higher energy loss

- Faster bit wear

- Frequent tool replacement

These factors increase project time and cost while reducing overall productivity.

Difficulty Controlling Drilling Depth and Position

Traditional methods make depth control less precise, which may lead to:

- Over-drilling or under-drilling

- Incorrect installation depth

- Mispositioned monitoring points

This can compromise pressure testing data or require costly re-drilling.

Greater Risk of Pipe Damage During Installation

When boreholes are uneven or unstable, inserting the pipe can create:

- Scratching

- Bending

- Mechanical stress

- Seal damage

In serious cases, it may even cause pipe failure.

Higher Overall Cost and Project Risk

All of the above challenges lead to additional cost and uncertainty, including:

- Re-drilling and repair work

- Delays in project schedules

- Higher labor and equipment expenses

- Increased safety risks

- Unreliable monitoring data

For projects where accuracy and safety are non-negotiable, these limitations make traditional methods increasingly inadequate.

How DTH Hammers Solve These Challenges

Down-the-Hole (DTH) hammer drilling technology places the hammer directly behind the drill bit, meaning the impact energy is transferred almost at the bottom of the borehole instead of from the top of the drill string. This unique design significantly improves drilling accuracy, energy efficiency, and borehole stability — making it particularly well-suited for the precise installation of pressure testing pipes.

Straighter Boreholes with Excellent Directional Control

Because the hammer is located close to the drill bit, DTH technology minimizes bending and vibration along the drill string. The result is:

- Much better borehole straightness

- Reduced deviation even in deep or hard-rock drilling

- Highly controlled drilling trajectory

This ensures that pressure testing pipes can be placed exactly where required, improving alignment, sealing integrity, and test accuracy.

Stable Borehole Walls and Reduced Collapse Risk

DTH hammers deliver a steady, controlled impact with lower lateral vibration than top-hammer systems. This helps maintain:

- Consistent borehole diameter

- Smooth and stable wall conditions

- Lower risk of collapse or enlargement

Stable boreholes make pipe insertion easier and improve seal performance, which is essential for obtaining accurate pressure readings.

Higher Efficiency in Hard and Abrasive Rock

DTH technology is designed for demanding rock conditions. Key advantages include:

- Faster penetration rates

- Higher drilling productivity

- Less energy loss

- Longer bit service life

This allows contractors to achieve both precision and efficiency, especially in mining, tunneling, and geotechnical drilling projects.

Accurate Depth and Position Control

Because drilling deviation and vibration are greatly reduced, DTH systems allow operators to control:

- Exact drilling depth

- Borehole angle

- Final positioning of the pressure testing pipe

This improves repeatability and ensures the monitoring point is installed at the correct structural location — which is critical for reliable data collection.

Lower Risk of Damage During Pipe Installation

With straighter geometry and smoother walls, the borehole environment is much more suitable for pressure testing pipe placement. This reduces the risk of:

- Pipe bending

- Abrasion damage

- Seal failure

- Insertion resistance

This means fewer installation problems and a lower risk of equipment failure or monitoring error.

Greater Safety and Lower Project Cost

By improving drilling accuracy and reliability, DTH hammer helps reduce:

- Re-drilling work

- Material waste

- Installation errors

- Operational downtime

- Overall project cost

At the same time, reduced vibration and better control also contribute to safer on-site working conditions.

Recommended Drilling Setup for Precision Pressure Testing Pipe Installation

Successfully installing pressure testing pipes requires not only a high-quality DTH hammer but also the right drilling setup and configuration. The following recommendations help ensure borehole accuracy, pipe stability, and reliable monitoring results.

Drill Rig & DTH Hammer Selection

Selecting the appropriate drill rig and DTH hammer is critical to match the geological conditions and project requirements. Key considerations include:

- Hole Diameter: Ensure the rig and hammer can drill the required borehole size to accommodate the pressure testing pipe without excessive clearance, which could affect alignment and sealing.

- Rock Hardness: Choose a DTH hammer that provides sufficient impact energy to penetrate the target rock efficiently. Harder rock formations may require hammers with higher impact frequency and energy.

- Air Supply Requirements: Proper air pressure and volume are essential for optimal hammer performance and for clearing cuttings. Insufficient air can reduce drilling efficiency and accuracy.

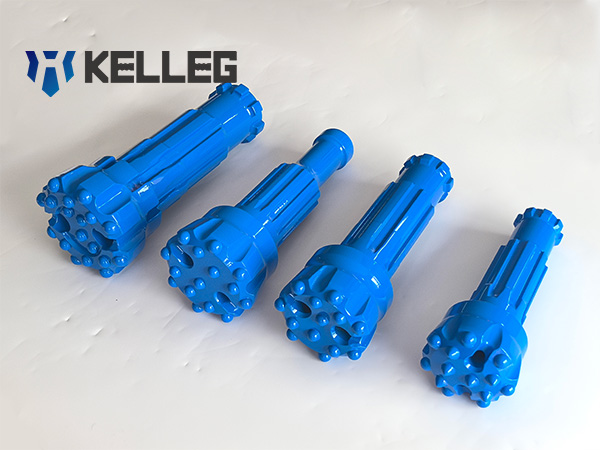

Drill Bit Selection

The drill bit design directly affects borehole stability, straightness, and penetration efficiency. Consider the following:

Bit Face Type

- Flat face bits are suitable for general drilling and provide good penetration.

- Concave bits improve debris removal in soft or fractured rock.

- Convex or dome-shaped bits are ideal for extremely hard rock and precision drilling.

Button Layout

A uniform button distribution ensures smooth rotation, minimizes deviation, and maintains borehole straightness — critical for accurate pipe placement.

Air and Dust Removal

Keeping the borehole clean is essential for both drilling performance and pipe installation:

- Ensure continuous air circulation to remove cuttings efficiently.

- Prevent accumulation of debris that may cause borehole blockage, deviation, or pipe misalignment.

- Proper flushing improves drilling speed and ensures a smooth borehole wall, facilitating easier pipe insertion.

Pipe Placement & Sealing Considerations

Even with precise drilling, careful handling during pipe installation is required:

- Prevent Pipe Deformation: Ensure borehole diameter matches pipe size and handle pipes carefully to avoid bending or damage.

- Maintain Measurement Accuracy: Use proper sealing materials and check alignment to guarantee reliable pressure readings. Misaligned or poorly sealed pipes can compromise monitoring data and system performance.

- Verify Position: Double-check pipe depth and alignment before final sealing to ensure installation meets design specifications.

Conclusion

The installation of pressure testing pipes demands high precision, stability, and reliability — all of which are achievable with the Down-the-Hole (DTH) hammer. By creating straighter, more stable boreholes, reducing deviation, and improving depth control, DTH hammers ensure that pipes are installed accurately and securely.

Accurate pipe placement is not just a technical requirement; it directly affects testing reliability, structural safety, and long-term project success. Even minor errors during installation can compromise monitoring data, damage equipment, or increase operational costs.

For projects where precision matters, investing in high-quality DTH hammers, drill bits, and proper drilling setups is essential. If you are planning a pressure testing pipe installation, consulting with experienced drilling experts can help select the right equipment and optimize your workflow — ensuring both accuracy and efficiency from start to finish.