Introduction

As drilling projects become more demanding, traditional drilling methods are increasingly challenged by high operating costs, low drilling efficiency, and limited adaptability to complex geological conditions. In hard, abrasive, or mixed formations, conventional techniques such as rotary or top hammer drilling often suffer from slow penetration rates, excessive tool wear, frequent downtime, and inconsistent borehole quality. These limitations make it difficult to meet modern project requirements for productivity, accuracy, and cost control.

In response to these challenges, pneumatic down-the-hole (DTH) hammers have emerged as a reliable and efficient drilling solution. By delivering high-impact energy directly behind the drill bit, pneumatic DTH hammers achieve strong penetration capability, maintain stable performance at greater depths, and adapt effectively to complex and variable rock formations. This design minimizes energy loss and significantly improves overall drilling efficiency.

Thanks to these advantages, pneumatic DTH hammers are widely used across a range of industries, including mining, geological exploration, infrastructure and foundation engineering, water well drilling, and geothermal projects. Their ability to combine efficiency, precision, and adaptability makes them an essential tool for modern drilling operations where performance and reliability are critical.

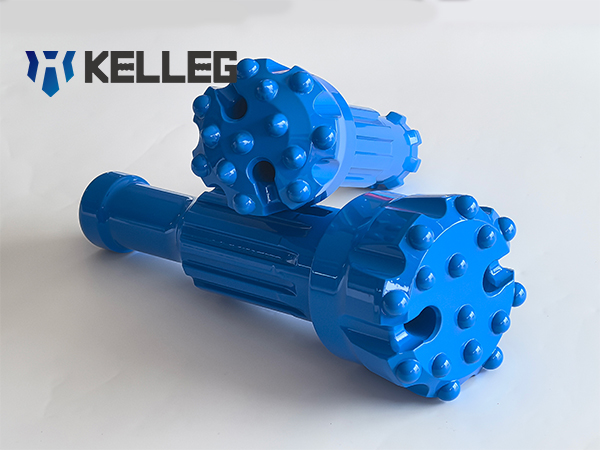

What Is a Down-the-Hole (DTH) Hammer?

A Down-the-Hole (DTH) hammer is a core component of a DTH drilling system. It is installed between the drill bit and the drill string, allowing impact energy to be generated directly at the bottom of the borehole. This design significantly improves drilling efficiency, accuracy, and performance—especially in hard and abrasive rock formations.

DTH hammers are typically classified according to their operating air pressure, including:

- Low-pressure DTH hammers

- Medium-pressure DTH hammers

- High-pressure DTH hammers

Each type is designed to match specific drilling conditions and compressor capacities.

Applications of DTH Hammers

DTH hammers are widely used across a broad range of engineering and industrial applications, including:

- Mining and quarrying

- Metallurgy and coal mining

- Geological exploration

- Water conservancy and hydropower projects

- Highway and railway construction

- Infrastructure and foundation engineering

- Defense and large-scale construction projects

Their ability to deliver high penetration rates, maintain borehole stability, and perform reliably in complex geological conditions makes DTH

hammers an essential tool in modern drilling operations.

How Does a DTH Hammer Work?

A DTH hammer operates using compressed air to drive a reciprocating piston that repeatedly strikes the drill bit. The working process can be summarized as follows:

At the start of the impact stroke, compressed air enters the upper chamber of the cylinder through air passages in the valve cover and valve seat. This high-pressure air pushes the piston downward at high speed, delivering a powerful impact directly to the drill bit.

As the piston moves downward, the pressure in the lower chamber gradually increases. When the piston reaches a specific position, the air pathways change, allowing compressed air to escape from the upper chamber. This pressure release marks the end of the impact stroke.

After the piston strikes the drill bit, the pressure difference between the upper and lower chambers causes the valve system to shift. The piston then moves upward, completing the return stroke. This cycle repeats continuously during drilling, producing consistent impacts that break the rock efficiently.

Key Factors That Enable Efficient Drilling with Pneumatic DTH Hammers

Pneumatic DTH hammers achieve high drilling efficiency by delivering impact energy directly to the rock face. Unlike conventional drilling systems, their performance remains stable as drilling depth increases, making them ideal for demanding geological conditions.

Superior Energy Transfer Efficiency

In pneumatic DTH drilling, compressed air drives the piston inside the hammer, generating impact energy directly at the bottom of the hole. This design minimizes energy loss during transmission.

Compared with top hammer drilling, where impact energy travels through long drill rods and dissipates with depth, pneumatic DTH hammers maintain consistent impact force regardless of hole depth. The result is:

- Higher effective energy utilization

- More stable drilling performance

- Reduced energy waste and operating costs

This depth-independent efficiency is a key reason why DTH hammers outperform traditional methods in deep and hard-rock drilling.

High Penetration Rates in Hard and Abrasive Rock

Pneumatic DTH hammers are specifically engineered for hard, abrasive, and fractured rock formations. By combining high-frequency impact with continuous rotation, they deliver fast and consistent penetration.

Typical formations where DTH hammers excel include:

- Granite

- Basalt

- Limestone

- Mixed and interbedded rock formations

In these conditions, traditional rotary or top hammer systems often experience rapid tool wear and declining penetration rates. Pneumatic DTH hammers, by contrast, maintain high penetration speed and longer service life, even under extreme drilling stress.

Improved Borehole Straightness and Stability

Because impact energy is applied directly behind the drill bit, pneumatic DTH hammers produce less vibration along the drill string. This significantly improves borehole control.

Key benefits include:

- Reduced hole deviation

- Improved borehole straightness

- Fewer corrective drilling actions

- Better accuracy for blasting, anchoring, and foundation work

Straighter boreholes not only improve drilling quality but also reduce time, rework, and material consumption—directly contributing to higher overall project efficiency.

Comparison: Pneumatic DTH vs Traditional Drilling Efficiency

| Performance Factor | DTH Hammer | Traditional Drilling Methods |

| Penetration Rate | High and consistent, especially in hard and abrasive rock | Decreases significantly in hard rock and with increasing depth |

| Energy Utilization | Direct impact at the bit results in minimal energy loss | Energy loss occurs through drill rods and the transmission system |

| Maximum Effective Depth | Excellent performance at greater depths; efficiency remains stable | Limited by energy dissipation and rod length |

| Hole Accuracy | High borehole straightness with minimal deviation | Higher deviation due to drill string bending and vibration |

| Downtime & Tool Wear | Lower downtime; optimized impact reduces bit and rod wear | Higher downtime due to frequent bit replacement and maintenance |

Key Conditions for Maximizing Drilling Efficiency with Pneumatic DTH Hammers

Achieving maximum drilling efficiency is not only about selecting a pneumatic DTH hammer—it requires proper system matching and operating conditions. The following factors have the greatest impact on performance, cost control, and drilling reliability.

1. Proper Air Pressure and Compressor Capacity

Compressed air is the driving force behind pneumatic DTH hammer performance.

- Insufficient air pressure reduces impact energy, penetration rate, and flushing efficiency

- Inadequate air volume (CFM) leads to poor cutting removal and premature tool wear

- Higher-pressure systems deliver stronger, more consistent blows, especially in hard rock

2. Correct DTH Hammer Size and Drill Bit Selection

Hammer and bit size directly affect drilling speed and hole quality. Drill bit diameter must be precisely matched to hammer specifications

3. Matching the Hammer to Rock Conditions

Rock formation characteristics play a decisive role in DTH performance.

- Hard and abrasive rock (granite, basalt): requires high-impact energy and wear-resistant materials

- Medium to soft rock (limestone, sandstone): benefits from optimized air distribution and stable impact frequency

- Mixed formations demand balanced energy output and robust internal components

4. Drill Rig Compatibility and System Integration

Even a high-performance DTH hammer cannot compensate for an incompatible drilling system.

- The drill rig must provide sufficient feed force and rotational torque

- Rod threads, shank design, and connection tolerances must align

- Stable mast alignment reduces vibration and hole deviation

Why Equipment Quality Matters for Efficient DTH Drilling

1. Material Selection and Heat Treatment

DTH hammers operate under extreme impact loads, high temperatures, and abrasive conditions.

- High-grade alloy steels provide superior fatigue resistance and impact strength

- Advanced heat treatment improves hardness without sacrificing toughness

- Optimized surface treatments reduce internal wear and corrosion

2. Precision Manufacturing and Tight Tolerances

- Accurate piston-to-cylinder clearance ensures smooth, powerful impacts

- Precision-machined air distribution systems improve energy efficiency

- Tight tolerances reduce air leakage and internal vibration

3. Consistent Performance Over Time

Efficiency is not just about peak performance—it’s about stability throughout the tool’s lifespan.

- High-quality DTH hammers maintain impact frequency and energy output

- Reduced performance degradation over long drilling cycles

- Predictable wear patterns simplify maintenance planning

4. Technical Support and Customization Capability

- Application-specific hammer and bit recommendations

- Custom configurations for pressure, depth, and formation conditions

- Technical guidance for setup, operation, and maintenance

Conclusion

Efficient drilling with pneumatic down-the-hole hammers is achieved through the optimal balance of energy efficiency, penetration capability, and operational stability. By delivering impact energy directly to the drill bit, DTH hammers minimize power loss, maintain consistent performance at greater depths, and achieve faster penetration in hard and complex formations.

When properly matched with air supply, drill rig, bit design, and rock conditions, pneumatic DTH systems provide reliable hole quality, reduced downtime, and lower cost per meter drilled. For modern drilling challenges, efficiency is not accidental—it is engineered through the right technology, quality equipment, and professional system configuration.

For best results, working with experienced DTH drilling tools specialists ensures maximum performance and long-term drilling reliability.