Introduction

Down-the-hole (DTH) drilling tools are a type of rock drilling system used to create deep, accurate holes in hard rock formations. Unlike top hammer drilling, where the impact energy is delivered from the surface, DTH drilling transfers the impact directly at the bottom of the hole through a DTH hammer and drill bit. This design allows the drilling energy to be fully utilized, resulting in higher penetration rates and better hole quality.

DTH drilling tools are widely used in mining, quarrying, tunneling, and foundation work because it offers consistent performance in challenging conditions. In mining and quarrying, DTH drilling tools are ideal for producing blast holes in hard, abrasive rock. In tunneling and foundation engineering, it provides precise hole accuracy and reliable drilling performance at depth. Its ability to maintain drilling efficiency even in deep holes makes it a preferred solution for many heavy-duty rock drilling applications.

What Are DTH Drilling Tools?

Definition of DTH (Down-The-Hole) Drilling

Down-the-hole (DTH) drilling is a method where the impact energy is delivered directly at the bottom of the hole through a DTH hammer and drill bit. The drilling system consists of a pneumatic hammer attached to the drill string, with the drill bit mounted at the front. Compressed air drives the DTH hammer piston, producing repeated impacts that break rock at the bottom of the hole.

Top hammer vs DTH drilling

- Top Hammer Drilling: Impact is delivered at the top of the drill string. Energy travels through drill rods, causing energy loss and reduced efficiency at greater depths.

- DTH Drilling: Impact occurs at the bottom of the hole, so the energy is applied directly to the rock, resulting in higher efficiency and better hole accuracy.

The key advantage of DTH drilling is that the impact energy is not lost during transmission, making it ideal for deep holes and hard rock formations.

Core Components of DTH Drilling Tools

DTH Hammer

The DTH hammer is the heart of the system. It converts compressed air into high-frequency impacts. The hammer contains a piston that moves back and forth inside a cylinder, striking the drill bit repeatedly. The hammer design determines impact energy, drilling speed, and service life.

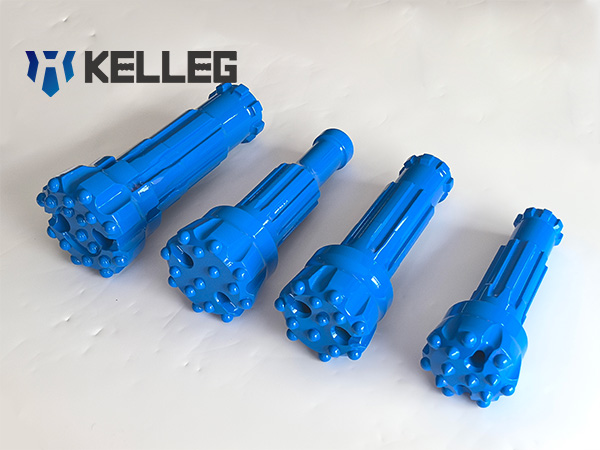

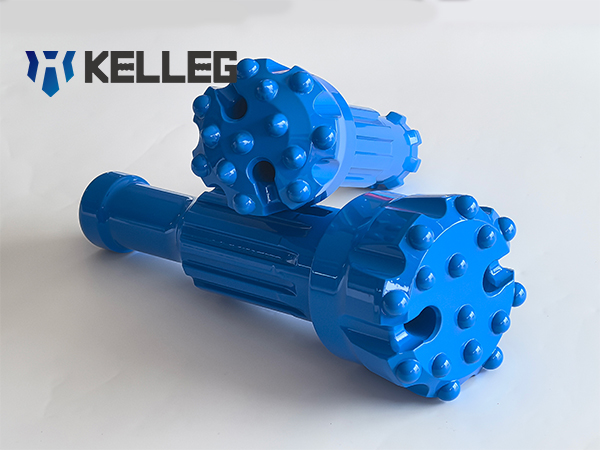

DTH Drill Bit

The drill bit is the part that directly contacts the rock. It is usually equipped with tungsten carbide buttons or inserts to resist wear and improve drilling performance. The bit face design (flat, convex, concave, etc.) affects the penetration rate, hole quality, and bit life.

Drill Pipe

Drill pipes connect the DTH hammer to the surface rig and transmit compressed air to the hammer. Drill pipes must be strong, wear-resistant, and compatible with the hammer’s connection system. They also provide stability and alignment for the drilling process.

DTH Drilling Tool Structure

DTH Hammer Structure

A DTH hammer is composed of multiple precision-engineered parts that work together under high-pressure air conditions. These components are designed to withstand intense impact and friction while maintaining stable performance over long drilling periods. The main parts of a DTH hammer include:

- Rear joint

- Front joint and transition joint

- Piston.

- Valve system

- Guide sleeve

- Spring and plug

- Rubber sealing rings

- Check valve

Each component must be manufactured with high precision and high wear resistance to ensure the hammer performs reliably in demanding drilling conditions.

DTH Drill Bit Structure

A DTH drill bit is the part that directly contacts and breaks rock at the bottom of the hole. Its structure determines drilling efficiency, hole quality, and tool life. The key components include:

- Skirt body: The main structure of the drill bit, usually made of high-strength steel. It supports the inserts and provides stability during drilling.

- Tungsten carbide buttons: Wear-resistant inserts placed on the bit face to crush and cut rock. The size, shape, and arrangement of buttons influence penetration rate and wear life.

- Bit face design: The shape and profile of the bit face (flat, concave, convex, or mixed designs) directly affect drilling performance, hole cleaning, and cuttings removal. Different face designs are optimized for different rock formations and drilling requirements.

Drill Pipe Structure

Drill pipes connect the DTH hammer to the drilling rig and deliver compressed air to the hammer. Their structure and material quality are critical for drilling stability and safety. The main structural aspects include:

- Thread type (API): The thread design determines compatibility between drill pipes, couplings, and hammer connections. API-standard threads are commonly used to ensure reliable and secure connections.

- Coupling design: Couplings connect two drill pipes and must be strong enough to withstand torque and bending forces during drilling. They also need to provide a stable and airtight seal.

- Material and fatigue resistance: Drill pipes must be made of high-strength alloy steel with excellent fatigue resistance to withstand repeated impacts, bending, and torsional stress over long drilling cycles.

How DTH Drilling Tools Work (Working Principle)

The Pneumatic Impact Mechanism

DTH drilling tools rely on a pneumatic impact mechanism to break rock efficiently. The process begins when compressed air is delivered from the surface through the drill pipe into the hammer body. Inside the hammer, the air pressure drives a piston back and forth. As the piston moves forward, it strikes the drill bit with high frequency and force.

Each piston impact transfers energy directly to the drill bit, which then crushes and fractures the rock at the bottom of the hole. This repeated impact action creates a stable drilling rhythm and allows the tool to penetrate hard rock formations with high efficiency. The key feature of DTH drilling is that the impact energy is applied directly at the drilling face, minimizing energy loss and maximizing penetration rate.

Air Flow and Energy Transfer

- Air flow plays a dual role in DTH drilling: it powers the impact mechanism and also clears cuttings from the hole.

- Air pressure vs impact force: Higher air pressure increases the piston’s impact force, resulting in stronger rock-breaking capability. However, pressure must be matched to the hammer design and bit size to avoid damage and reduce wear.

- Air volume vs flushing capacity: Air volume determines how effectively cuttings are removed from the hole. Higher airflow improves hole cleaning and prevents clogging, especially in deep drilling or highly fractured rock.

- Role of air in cooling and removing cuttings: The air stream not only carries cuttings out of the hole but also cools the bit. This reduces heat-related wear and maintains stable drilling performance.

A balanced air pressure and air volume combination is essential to achieve optimal drilling speed and tool service life.

How to Choose the Right DTH Drilling Tool

Choosing the right DTH drilling tool is crucial for achieving high drilling efficiency, lower operating costs, and longer service life. The correct selection depends on drilling objectives, rock formation, tool compatibility, and air supply.

Start with the Drilling Objective

Before selecting a DTH hammer or drill bit, define the purpose of the drilling project:

- Production drilling vs exploration drilling:

* Production drilling requires higher drilling speed, stable performance, and cost efficiency. It often involves long drilling cycles and large hole volumes.

* Exploration drilling focuses on accuracy and data collection. It may require smaller hole diameters and better hole straightness.

- Hole quality requirement (accuracy, straightness):

If your project requires precise hole alignment, such as for anchoring, foundation piles, or controlled blasting, you should choose a tool combination that offers better stability and bit guidance. Bit design and hammer balance significantly influence hole straightness.

Choose Based on Rock Formation

Rock type is one of the most important factors in selecting DTH tools. Different rock formations require different bit designs and hammer types:

- Soft rock: Soft formations usually require lower impact energy and a bit with a large cutting area. A lower-pressure hammer with a wide face bit can improve drilling speed and reduce wear.

- Medium hardness rock: For medium rock, choose a balanced DTH hammer and bit combination. A standard button bit with an optimized button layout can provide stable performance.

- Hard rock: Hard rock requires high impact energy and strong bit buttons. High-pressure DTH hammers paired with a bit designed for hard formations are preferred to achieve high penetration rates.

- Highly abrasive rock: In highly abrasive conditions, tool wear becomes the main issue. Select a bit with long-life tungsten carbide buttons and consider a DTH hammer designed for high wear resistance. Frequent bit replacement may still be required, so choosing a durable tool is essential for reducing cost per meter.

Match the DTH Hammer and Bit Correctly

Ensure the bit shank matches the hammer’s connection type. Different hammer models use different shank standards (e.g., threaded or special couplings). Using an incompatible bit can cause poor sealing, reduced impact efficiency, and accelerated wear.

Select Based on Air Compressor Capacity

Air supply is the power source of DTH drilling. If the air compressor cannot meet the required pressure and volume, drilling performance will drop significantly:

- Minimum air pressure requirements:

Each hammer model has a minimum operating air pressure. Operating below this pressure reduces impact force and penetration rate.

- Recommended air volume (CFM / m³/min):

Air volume determines flushing efficiency and cutting removal. Insufficient airflow will cause poor hole cleaning, bit clogging, and reduced drilling speed. Choose a compressor that can provide stable pressure and sufficient airflow for the selected hammer and bit size.

DTH Drilling vs Other Drilling Methods

| Feature | DTH Drilling | Top Hammer Drilling | Rotary Drilling |

| Depth | High | Limited | Variable |

| Hole quality | High | Medium | High |

| Energy loss | Low | High | Medium |

| Best for | Hard rock | Soft-medium rock | Mixed rock |

Conclusion

Down-the-hole (DTH) drilling tools are one of the most efficient solutions for deep-hole and hard rock drilling. By delivering impact energy directly at the bottom of the hole, DTH technology minimizes energy loss and maintains stable drilling performance even in challenging formations. This makes it the preferred choice for mining, quarrying, tunneling, and foundation projects that require high penetration rates and consistent hole quality.

However, achieving the best performance and lowest drilling cost depends on selecting the right tool combination. Correctly matching the DTH hammer, bit, and air supply to the rock conditions and drilling objectives is essential. With the right DTH drilling tools and proper system configuration, operators can significantly improve drilling efficiency, reduce tool wear, and lower overall operational costs.