Introduction

Choosing the right drill bit is one of the most important factors in achieving efficient and cost-effective rock drilling. Rocks vary widely in hardness, abrasiveness, and structural composition, so using the wrong bit type can lead to slow penetration rates, excessive wear, frequent replacements, and higher operational costs. On the other hand, selecting the correct drill bit ensures faster drilling, longer tool life, and improved overall productivity.

Rock hardness and drilling conditions significantly influence a drill bit‘s performance. Hard formations like granite or basalt require bits with high-strength carbide buttons or diamond cutting structures, while medium or soft formations may perform better with different bit designs or materials. Factors such as drilling method, hole depth, air pressure, and equipment compatibility also influence bit efficiency and lifespan.

Several specialized drill bit types are used in rock drilling depending on the application. These include Down-the-Hole (DTH) drill bits, Top Hammer drill bits, Tricone rotary bits, PDC bits, and diamond core bits. Each type is engineered for specific rock conditions and project requirements. Understanding their differences helps users choose the most suitable option for mining, construction, quarrying, or geological exploration.

What Makes Rock Drilling Different?

Drilling through rock is fundamentally different from drilling into softer materials like soil, wood, or concrete. Rock presents unique challenges due to its physical properties, requiring specialized drill bits designed to withstand extreme conditions.

Characteristics of Rock

Rock materials vary significantly, but most share three key characteristics that directly affect drilling performance:

- Hardness:

Rocks such as granite, basalt, and quartzite are tough, requiring drill bits with high-strength carbide buttons or diamond cutting structures. Softer rocks like limestone drill more easily but may still cause wear over time.

- Abrasiveness:

Many rocks contain hard mineral grains that can quickly wear down cutting edges. Highly abrasive formations demand bits made from wear-resistant materials and optimized face designs.

- Fracturing and Structure:

Rocks often contain natural fractures, joints, and layers. These structural variations can cause bit deviation, uneven wear, or even bit breakage if the bit is not properly matched to the formation.

Why Standard Bits Fail in Rock Applications

Drill bits designed for wood, metal, or light concrete are not built to handle the extreme impact, heat, and abrasion generated during rock drilling. Standard bits commonly fail because:

- They lack the impact resistance needed to penetrate hard formations.

- Their cutting edges wear out rapidly when exposed to abrasive minerals.

- They cannot withstand the high torque and vibration required for rock drilling.

- They usually overheat because they are not engineered for the cooling or flushing systems used in rock drilling (air or water circulation).

- Using standard bits on rock not only reduces efficiency but can also damage drilling equipment and increase operational costs.

Where Rock Drilling Takes Place

Rock drilling is essential across several heavy-industry sectors, each with unique requirements:

- Mining:

Used for blast hole drilling, core sampling, and exploration in both surface and underground mines.

- Construction:

Involved in foundation works, anchoring, tunneling, and infrastructure projects that require drilling through rock layers.

- Quarrying:

Employed to break solid rock for aggregate production and material extraction.

- Geotechnical Exploration:

Used for obtaining core samples to assess ground stability and geological conditions before major engineering projects.

These environments demand drill bits that maintain high penetration rates, stability, and durability, even under extreme working conditions.

Main Types of Drill Bits for Rock Drilling

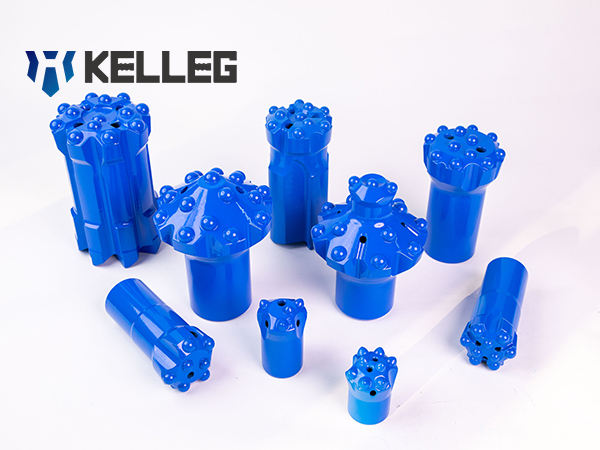

Top hammer rock drill bit

The top hammer rock drill bit is a tool component. The drill bit body is made of high-quality steel, with carbide buttons produced through specialized processing and welding techniques. These bits are widely used in various mining projects. The classifications include chisel bits, cross bits, three-edge drill bits, and button bits.

1. The chisel bit is suitable for light rock drills to drill rock formations with low hardness, which are easy to grind.

2. The cross-bit and X-bit are suitable for drilling fractured rock formations and abrasive rock formations under the conditions of rock drills with high impact power, and have strong resistance to radial abrasion.

3. The button bit is more suitable than the sheet insert drill bit for rock drills with high-impact power. It offers higher rock drilling speed, longer service life, and produces rounder hole types.

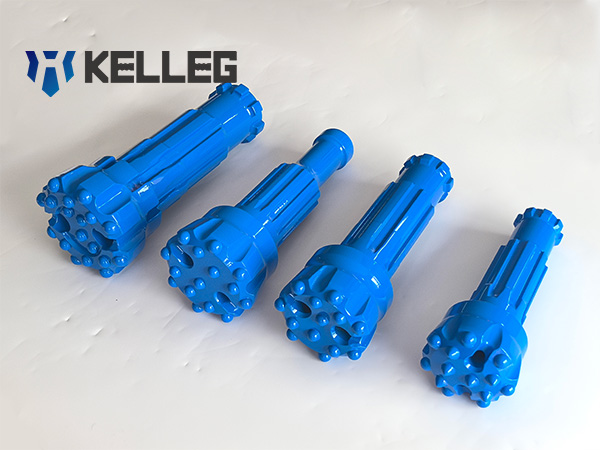

DTH drill bit

The DTH drill bit is a kind of drill tool connecting the impactor with the spline of the drill bit to guide and transmit the rotation for the impact, with the drill bit and the DTH hammer diving into the hole to break the rock. DTH drill bits include high, medium, and low wind pressure DTH drill bits. There are mainly four types of end-face designs: convex type, flat type, concave type, and deep concave center type.

- Convex type: It can maintain a high rock drilling rate when drilling medium-hard and hard abrasive rocks, but the straightness of the drilled hole is poor, which is not suitable for rock drilling projects with high requirements for blast hole straightness.

- Flat type: It is relatively strong and durable, suitable for drilling hard and ultra-hard rocks, and suitable for drilling medium-hard rocks and soft rocks with low requirements for blast hole straightness.

- Concave type: There is a conical concave part on the end face, which is a slight nucleation effect formed by the drill bit during the rock drilling process to maintain the centering performance of the drill bit. The drilled blast hole has good straightness. This drill bit has a good powder removal effect and a fast drilling speed.

- Deep concave center type: It is used for nucleation during rock drilling and ensures the straightness of the blast hole when drilling deep holes. It is only suitable for drilling soft rock and medium hard rock.

Rotary drill bits

When the rotary drill bit is working, the cutting teeth contact the bottom of the well alternately, the rock-breaking torque is small, the contact area between the cutting teeth and the bottom of the well is small, the specific pressure is high, and it is easy to eat into the formation; the total length of the working edge is long, so the wear is relatively reduced. Rotary drill bits can adapt to a wide range of formations, from soft to hard. According to the number of cones, there are single, double, triple, and multi-cone bits. The roller cone bit is the most widely used and common type domestically and internationally. Rotary drill bits are an essential and crucial component in the oil, earth, and various drilling industries.

PDC drill bit

PDC drill bit is a drill bit with a circular composite piece welded to a cylindrical cutting tool, and the cutting tool is mounted on the drill bit body. It includes PDC drill bits for geological exploration, PDC drill bits for coalfield drilling, and PDC drill bits for oil exploration.

PDC drill bits for geological exploration: Composite drill bits are primarily used for geological exploration and are suitable for soft to medium-hard rock formations. Recently, some manufacturers have developed new composite pieces that can be applied to rock formations with a hardness of up to ten levels.

PDC drill bits for coalfield drilling: mainly used for drilling and mining coal seams in coal mines. Generally speaking, the rock formations in coalfields are relatively soft, and composite drill bits are widely used, such as anchor drill bits and three-wing drill bits.

PDC drill bits for oil exploration: mainly used in drilling and using drill bits in oil and gas fields. Currently, composite drill bits for oilfields are the most expensive and demanding of all composite drill bits. It can be said to be the aristocrat among composite drill bits.

How to Choose the Right Drill Bit for Rock

Choosing Based on Rock Hardness

Rock hardness is one of the most important factors in bit selection. Matching the bit type to formation hardness improves drilling efficiency and prevents premature wear.

- Soft Rock (e.g., limestone, shale)

→ Recommended bits: Tricone bits, PDC bits

These bits cut efficiently through softer formations and provide long bit life.

- Medium-Hard Rock (e.g., sandstone, dolomite)

→ Recommended bits: DTH bits, Tricone bits

DTH bits offer stable penetration in moderately hard rock, while tricones perform well in mixed formations.

- Hard Rock (e.g., granite, basalt, quartzite)

→ Recommended bits: DTH bits, Top Hammer bits, Diamond bits

These bits feature strong carbide buttons or diamond structures designed to withstand extreme hardness and high impact.

Choosing Based on Drilling Method

Different drilling methods require specific bit designs to deliver optimal performance.

- Percussive Drilling (impact drilling)

Examples: Top hammer, DTH drilling

→ Best suited for hard and abrasive rock

→ Bits must handle repeated high-impact force.

- Rotary Drilling (continuous cutting without impact)

Examples: Tricone bits, PDC bits

→ Ideal for soft to medium-hard rock

→ Offers smoother, high-speed cutting.

When selecting a bit, consider whether the project requires:

- Deep-hole drilling (best with DTH or rotary systems)

- High-speed drilling (ideal with PDC or tricone bits)

- Precision drilling (diamond core bits recommended for accuracy and sample recovery)

Choosing Based on Hole Diameter and Depth

Hole size and depth influence bit selection.

- Small, Shallow Holes

→ Recommended bits: Taper bits

Common for construction, small anchors, and lightweight drilling.

- Deep, Large-Diameter Holes

→ Recommended bits: DTH bits, Tricone bits

These bits provide stability and efficient cutting removal at depth.

- Core Sampling or Geological Exploration

→ Recommended bits: Diamond core bits

Offer excellent accuracy and preserve the integrity of geological samples.

Selecting Bit Material and Button Shape

Material composition and button geometry significantly impact durability and penetration rate, especially in hard or abrasive formations.

Tungsten Carbide Grades

Carbide quality determines resistance to wear, heat, and impact.

- Tough grades → suitable for hard, fractured rock

- Wear-resistant grades → best for abrasive formations

Button Types

- Spherical Buttons

→ Perfect for very hard or abrasive rock

→ Offer superior durability and maintain shape under heavy load.

- Ballistic Buttons

→ Ideal for soft to medium-hard rock

→ Provide faster penetration but wear quickly in hard formations.

Bit Face Designs

- Flat Face

→ Good for hard, abrasive rock

- Concave Face

→ Helps with hole straightness, suitable for most conditions

- Convex Face

→ Best for fast penetration in soft formations

Choosing the right combination of button shape, carbide grade, and face design ensures the bit performs efficiently while maintaining long service life.

Key Factors That Affect Rock Drilling Efficiency

Achieving high rock drilling efficiency depends on more than just choosing the right drill bit. Several operational factors play a critical role in penetration rate, bit lifespan, and overall productivity. Understanding these factors helps operators improve performance and reduce operating costs.

Proper Air Pressure or Impact Power

Rock drilling requires sufficient force to break and remove material.

- In DTH drilling, consistent and adequate air pressure is essential to drive the hammer and clear cuttings from the hole. Low air pressure reduces impact power, increases friction, and slows penetration.

- In top hammer drilling, impact power must be matched to rock hardness. Too little power reduces drilling speed, while excessive power can cause bit breakage or rod failures.

- Maintaining optimal pressure and impact settings ensures smooth drilling and prevents unnecessary tool wear.

Matching the Bit to the Hammer or Drill Rig

Using a bit that is incompatible with the drill rig or hammer setup can significantly affect performance.

- Bit diameter must suit the hammer size and rig capability.

- Button configuration and face design should match operating conditions.

- The drill string, hammer, and bit must work as a coordinated system to maintain maximum energy transfer.

Correct matching results in higher penetration rates, reduced vibration, and longer tool life.

Cooling Requirements

Drilling generates extreme heat and friction, especially in hard or abrasive formations. Proper cooling extends the bit life and prevents overheating.

- In DTH and top hammer systems, compressed air is used to cool the bit and clean the borehole.

- Insufficient cooling can cause thermal damage, reduced penetration, and accelerated wear.

Wear Inspection and Bit Replacement Timing

Regular inspection is critical to maintaining drilling efficiency. Worn-out bits lead to slower drilling, increased energy consumption, and potential damage to the hammer.

Operators should routinely check for:

- Flattened or chipped carbide buttons

- Cracks in the bit body

- Excessive gauge wear

Replacing bits at the right time ensures consistent performance and minimizes unplanned downtime.

Common Problems When Drilling Rock (and How to Avoid Them)

Rock drilling often presents challenges that can reduce productivity, increase operational costs, and damage equipment. Understanding the most common issues—and how proper bit selection can prevent them—helps operators maintain efficient and stable drilling performance.

Bit Breakage

Bit breakage typically occurs when drilling in extremely hard, fractured, or abrasive formations.

Causes include:

- Using an incorrect bit type for rock hardness

- Excessive impact power or wrong drilling parameters

- Poor bit design for the rock structure

How to avoid it:

- Use DTH or top hammer bits with spherical carbide buttons for tough and abrasive formations.

- Match bit diameter and design to the hammer size and drilling conditions.

- Reduce impact power when drilling through fractured zones.

Premature Wear

Premature wear results in reduced drilling speed, poor hole quality, and frequent bit replacements.

Causes include:

- High abrasiveness of rock

- Insufficient cooling or air flushing

- Incorrect carbide grade or button shape

How to avoid it:

- Choose bits with high wear-resistant carbide grades for abrasive rock.

- Ensure proper air pressure and cooling to reduce heat buildup.

- Use the correct face design—flat or concave faces handle wear better in tough formations.

Slow Penetration Rate

A low penetration rate greatly impacts productivity and fuel consumption.

Causes include:

- Using the wrong bit type for rock hardness

- Dull or worn carbide buttons

- Low-impact power or improper drilling settings

How to avoid it:

Select bits optimized for the formation:

- Ballistic buttons for softer rock

- Spherical buttons for hard rock

- Maintain proper hammer pressure and energy transfer.

- Replace worn bits before they significantly reduce drilling speed.

Hole Deviation

Hole deviation occurs when the drill path drifts off the intended line, especially in fractured or layered rock.

Causes include:

- Incorrect bit face design

- Poor energy transfer from hammer to bit

- Geological changes such as cracks or voids

How to avoid it:

- Use bits with a concave or flat face for better hole straightness.

- Ensure proper alignment between the drill string and bit.

- Adjust drilling parameters when entering fractured zones.

By matching bit type, material, button shape, and face design to the specific rock conditions, operators can achieve efficient, stable, and reliable drilling performance.

Conclusion

Selecting the right drill bit is essential for achieving efficient, reliable, and cost-effective rock drilling. Matching the bit type with the drilling method, hole depth, and rock hardness ensures optimal penetration rates, longer service life, and reduced operational costs.

Beyond choosing the correct bit design, selecting a reliable and experienced manufacturer is critical to drilling success. High-quality materials, precise manufacturing, and advanced engineering ensure that the drill bits perform consistently even in the toughest drilling environments.

For the best results, customers should always choose drill bits that are engineered specifically for their project requirements. Whether the goal is faster penetration, improved durability, or accurate geological sampling, using the right bit ensures better performance and maximizes the value of every drilling operation.